Introduction

The engineering industry is under increasing pressure to improve efficiency, reduce costs, and innovate faster. Traditional methods are no longer sufficient to meet the rising demand for precision, speed, and sustainability in engineering projects.

Artificial Intelligence (AI) is emerging as a transformative force, offering solutions that enhance design, manufacturing, and maintenance processes. In this guide, we explore how AI is revolutionizing engineering, from optimizing product design to predictive maintenance and automated quality control, unlocking substantial value for businesses.

What is AI and Why Does It Matter in Engineering?

Definition of AI and Its Core Technologies

AI involves the use of computer systems to simulate human-like intelligence, such as learning, problem-solving, and decision-making. The core technologies driving AI in engineering include machine learning (ML), computer vision, and natural language processing (NLP). These technologies empower machines to analyze vast datasets, recognize patterns, and make decisions that traditionally required human expertise.

In the context of engineering, AI can be applied in various ways, from automating repetitive design tasks to optimizing production processes and enabling predictive maintenance of complex machinery. AI helps engineers tackle the increasing complexity of modern projects while improving accuracy, efficiency, and overall performance.

The Growing Role of AI in Transforming Engineering

AI is gradually reshaping engineering by automating time-consuming tasks and enabling more sophisticated design, manufacturing, and maintenance processes. In product design, AI accelerates innovation by using generative design, where algorithms create multiple design alternatives that meet predefined constraints, allowing engineers to explore new possibilities and reduce material costs. This can drastically shorten product development timelines and create more efficient designs.

In manufacturing, AI integrates into smart factories, using data from sensors and machines to optimize production lines and prevent bottlenecks. AI models analyze production data in real-time to predict failures before they happen, making it possible to reduce downtime and improve operational efficiency.

For maintenance, AI is enabling predictive maintenance, where AI systems monitor the health of equipment, predict failures, and recommend the most optimal maintenance schedule. This helps organizations avoid costly repairs, extend equipment life, and improve the reliability of critical systems.

Key Statistics and Trends in AI Adoption in Engineering

AI adoption in engineering is rapidly increasing as companies seek to optimize operations, reduce costs, and foster innovation. According to a 2023 report from McKinsey & Company, 70% of engineering firms have already integrated AI into their operations, with manufacturing being the leading sector for AI applications. This adoption is expected to rise, with 90% of firms planning to use AI-driven tools by 2027.

The 2024 Industry 4.0 report by PwC highlights that AI-powered predictive maintenance solutions have already helped reduce downtime by 30-40% in industries like oil and gas and automotive manufacturing. Additionally, AI-based quality control systems are reducing defect rates by 20%, improving both production efficiency and product quality.

AI in engineering design is also growing, with a 2023 Deloitte survey finding that 60% of engineers in the aerospace sector are utilizing AI-powered generative design tools to reduce design time by 40% and material costs by 15%. This trend is expected to continue, as generative design is becoming a core component of innovation in engineering processes.

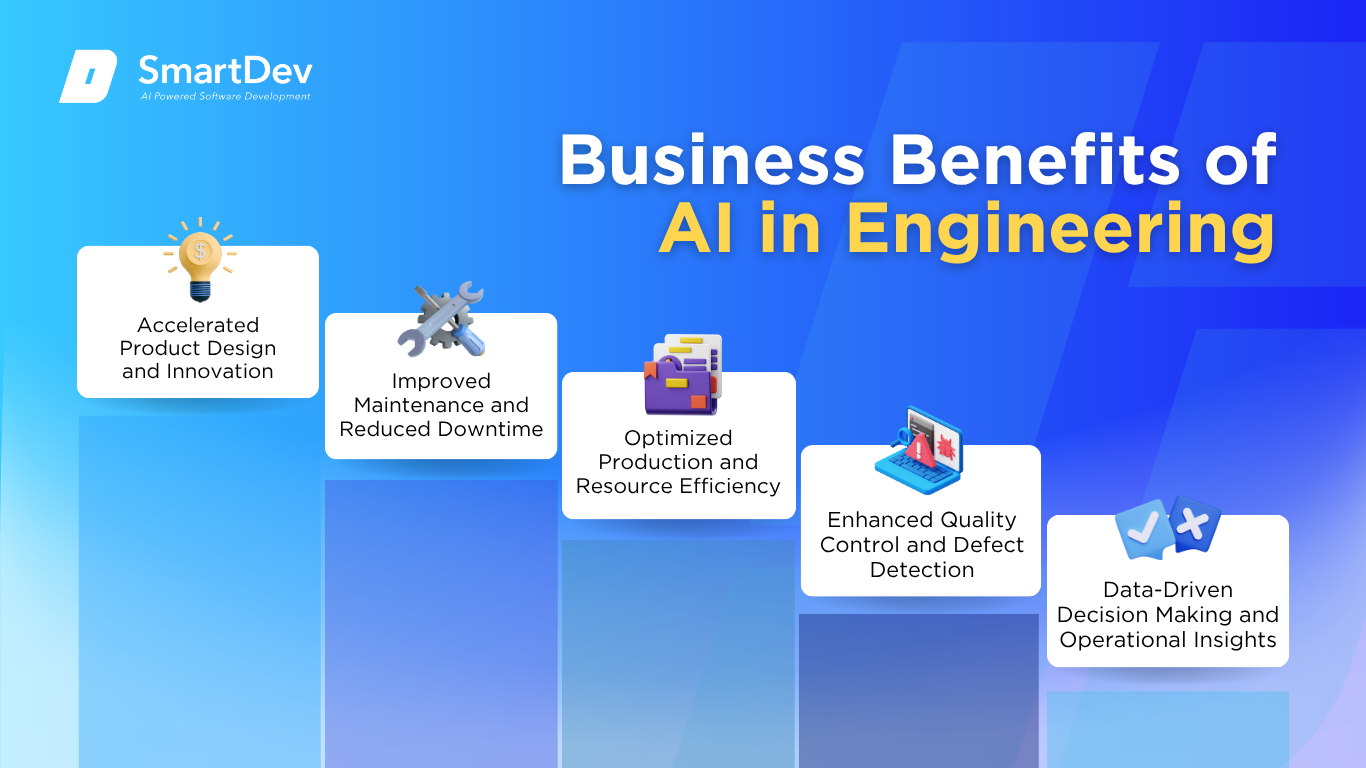

Business Benefits of AI in Engineering

AI is delivering measurable value in the engineering industry by solving key challenges such as inefficiencies in design, high operational costs, equipment downtime, and slow innovation cycles. Below are five key benefits that demonstrate how AI is creating tangible improvements across various engineering functions.

1. Accelerated Product Design and Innovation

AI significantly accelerates the product design process. Traditional design methods can be time-consuming, requiring multiple iterations and manual adjustments. AI, particularly through generative design algorithms, allows engineers to input design parameters (such as materials, weight, strength, and budget), and then generate a multitude of optimized design alternatives in a fraction of the time.

This shift from a manual to an AI-driven design process promotes faster iteration and encourages more innovative solutions. With generative design, engineers can explore unconventional and highly optimized designs that they might not have considered using traditional methods. This leads to faster time-to-market and the development of products that are not only cost-efficient but also innovative in terms of functionality and performance.

2. Improved Maintenance and Reduced Downtime

AI-powered predictive maintenance transforms how engineering teams approach the maintenance of machinery and equipment. In traditional setups, maintenance is often reactive, equipment is serviced only after a failure or breakdown occurs. AI shifts this model to a predictive approach, where machine performance is continuously monitored, and potential failures are identified before they occur.

Through the analysis of real-time data from sensors embedded in machines, AI can detect subtle patterns or anomalies that might indicate an impending issue. By acting proactively, companies can reduce unplanned downtime, avoid costly repairs, and extend the lifespan of their equipment. Predictive maintenance not only reduces operational costs but also enhances productivity by ensuring that equipment runs optimally without unexpected interruptions.

3. Optimized Production and Resource Efficiency

AI plays a critical role in optimizing production schedules and resource allocation within engineering and manufacturing environments. Traditional production systems rely on historical data and human input to determine workflows, but AI goes a step further by analyzing real-time production data and identifying inefficiencies or bottlenecks in the system.

By leveraging machine learning and optimization algorithms, AI can recommend adjustments to workflows, predict demand, and ensure that resources such as raw materials, labor, and machinery are allocated where they’re needed most. This dynamic optimization helps businesses reduce waste, maximize the use of resources, and enhance the overall efficiency of their production lines. As a result, engineering firms can lower costs, speed up production, and improve their ability to meet customer demand.

4. Enhanced Quality Control and Defect Detection

AI’s ability to monitor and inspect production processes in real time provides a significant advantage in quality control. Traditional manual inspection methods can be slow, error-prone, and inconsistent, especially when dealing with high volumes of products or intricate designs. AI, particularly computer vision systems, can rapidly analyze images and sensor data, detecting defects or inconsistencies with high accuracy.

By automatically identifying faulty products or deviations from quality standards, AI improves the consistency and precision of quality control processes. This results in fewer defective products reaching customers, reducing scrap rates, and minimizing the need for rework. Enhanced quality control through AI also reduces operational costs and strengthens customer satisfaction by ensuring that only products of the highest quality are delivered.

5. Data-Driven Decision Making and Operational Insights

AI empowers engineers with actionable insights drawn from vast amounts of data, which they can use to make more informed decisions. In engineering projects, there is often an overwhelming amount of data coming from multiple sources, such as performance metrics, sensor data, market trends, and historical performance. AI algorithms can process and analyze this data at scale, revealing patterns, correlations, and insights that might otherwise go unnoticed.

This data-driven approach allows engineering teams to make decisions based on real-time information rather than relying solely on intuition or past experience. AI helps engineers optimize designs, predict potential issues, and identify opportunities for process improvements. Ultimately, this leads to more effective decision-making, reducing errors, enhancing operational efficiency, and driving better business outcomes.

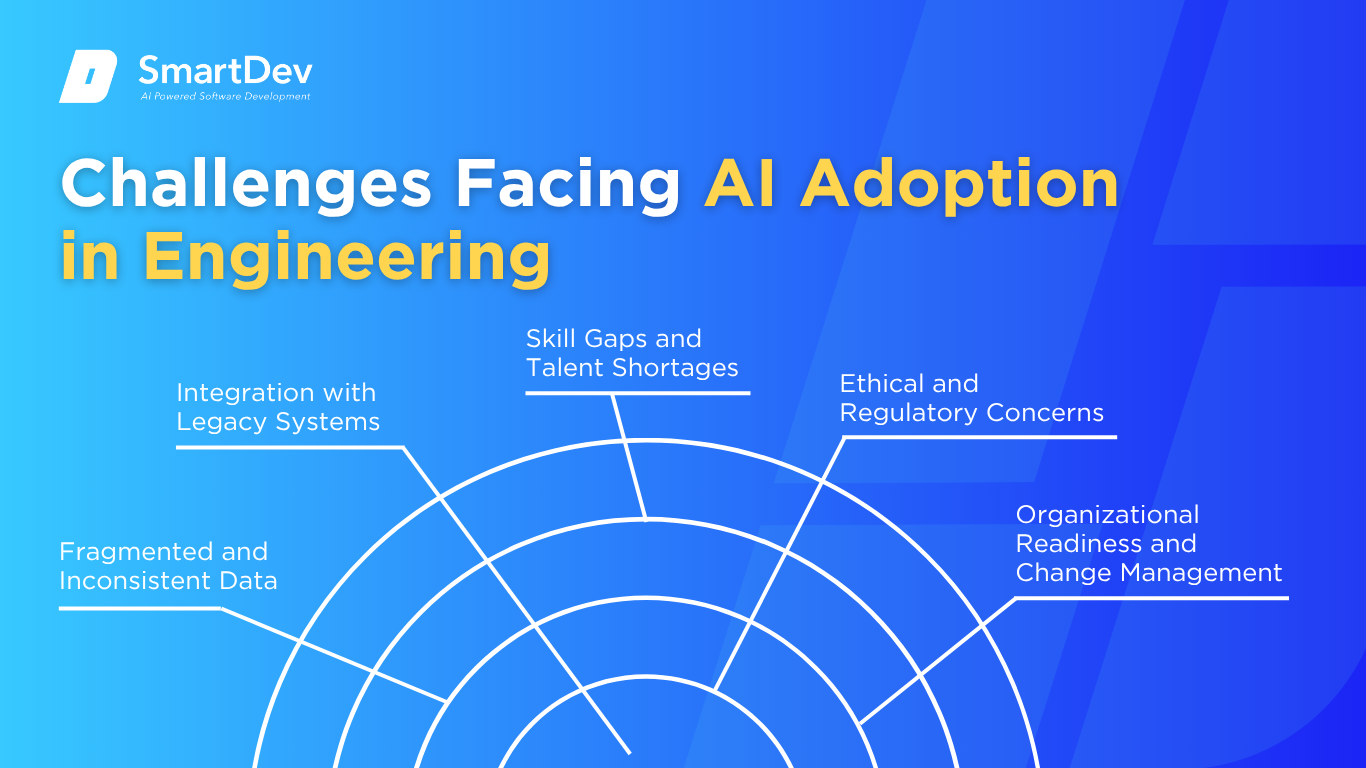

Challenges Facing AI Adoption in Engineering

While AI offers immense benefits to the engineering sector, its adoption comes with several challenges that organizations must overcome to successfully integrate this technology. From data integration issues to the complexities of changing organizational structures, these barriers can impact the seamless implementation of AI solutions.

1. Fragmented and Inconsistent Data

AI systems rely on unified, high-quality data to function effectively. However, many engineering firms have data spread across various systems, making it difficult for AI to create a complete picture. Fragmented data reduces the accuracy and effectiveness of AI models, hindering their ability to generate reliable insights.

To address this, organizations must invest in data centralization and ensure that departments collaborate and share consistent information. Building a unified data infrastructure is key to enabling AI to operate effectively across all systems. This requires a commitment to improving data management practices across the business.

2. Integration with Legacy Systems

Many engineering companies rely on legacy systems that aren’t compatible with AI technologies. Integrating AI with outdated systems can be complex, expensive, and disruptive to operations. This makes it challenging to leverage AI’s full potential within established infrastructures.

To overcome this challenge, firms need to modernize legacy systems or ensure that new AI tools can be integrated seamlessly. Upgrading systems and implementing clear integration strategies will ensure that AI can work effectively with existing tools. Careful planning is essential to avoid disrupting ongoing projects.

3. Skill Gaps and Talent Shortages

AI in engineering requires expertise in data science, machine learning, and AI technologies. However, there is a shortage of skilled professionals in these areas, which makes AI implementation difficult. Engineering firms must compete to attract and retain the necessary talent to drive AI initiatives forward.

Addressing this requires a focus on upskilling existing employees and investing in training programs. Companies may also need to partner with educational institutions or hire external experts to fill the skill gap. Building a talent pipeline is crucial for sustaining long-term AI adoption.

4. Ethical and Regulatory Concerns

AI’s role in decision-making can raise ethical questions, particularly regarding worker safety, product design, and environmental impact. Additionally, AI adoption in engineering must comply with industry regulations, which are often evolving. Missteps in addressing these concerns can result in legal issues or damage to a company’s reputation.

To mitigate these risks, firms must ensure transparency and ethical decision-making in AI systems. Implementing governance frameworks and staying up-to-date with regulations will help organizations navigate potential challenges. Ethical AI practices are critical for maintaining trust and compliance.

5. Organizational Readiness and Change Management

Introducing AI requires significant organizational change, which can be met with resistance from employees. Concerns about job displacement or unfamiliar technologies can hinder AI adoption. Overcoming resistance requires effective change management, clear communication, and ongoing support.

Companies must focus on creating a culture that embraces AI and offers training to help staff adapt. Engaging employees early and addressing their concerns can lead to smoother implementation. Successful AI adoption relies on strong leadership and commitment to workforce development.

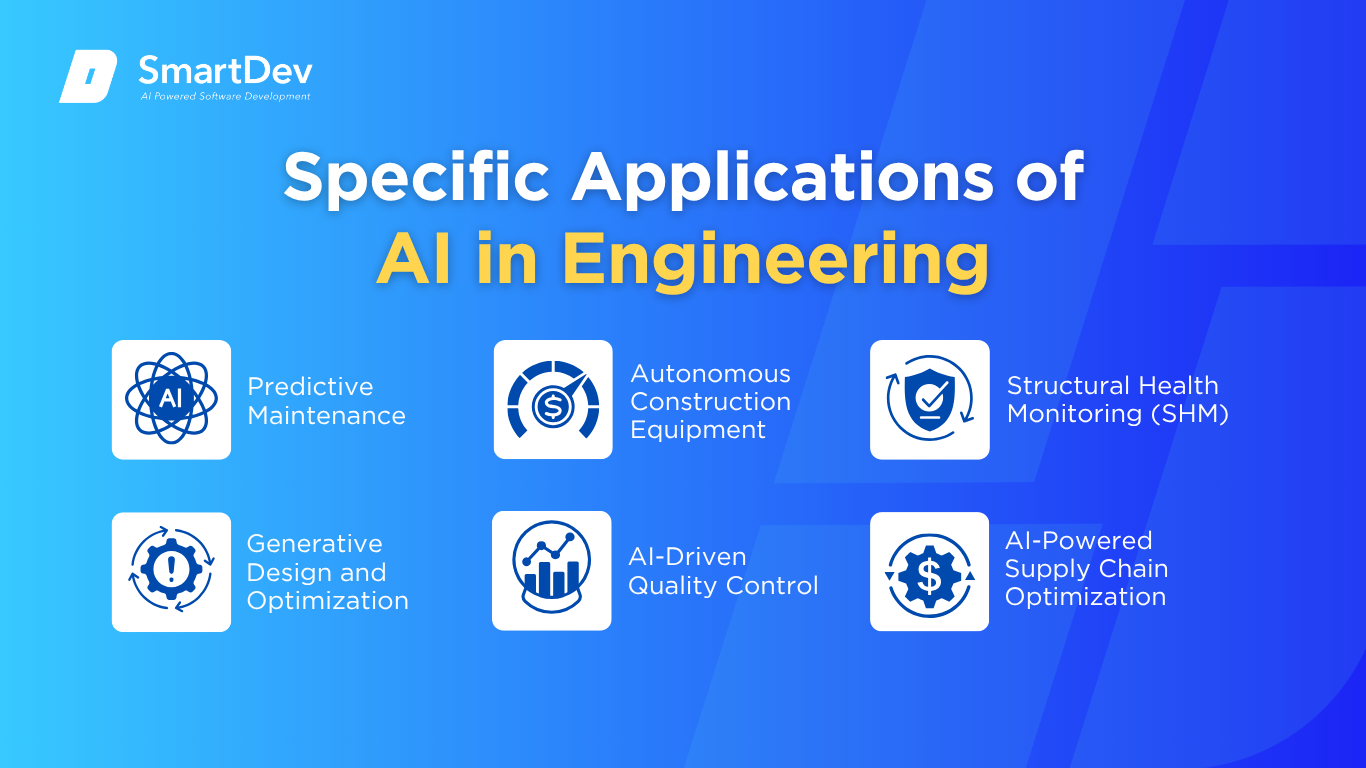

Specific Applications of AI in Engineering

1. Predictive Maintenance

Predictive maintenance uses AI algorithms to analyze real-time data from sensors embedded in machines, equipment, or structures to predict when a failure might occur. In engineering, this application helps avoid the costly and disruptive impact of unexpected machine downtime. The AI model processes historical performance data, usage patterns, and environmental conditions to identify patterns that suggest imminent failures.

The machine learning models used in predictive maintenance are typically trained on large datasets that include sensor data, equipment performance records, and environmental conditions. Once deployed, these models can continually analyze data streams and flag potential issues before they become critical. As a result, predictive maintenance can extend equipment lifespans, reduce maintenance costs, and optimize the scheduling of repairs.

General Electric (GE) employs AI for predictive maintenance in its aviation and energy sectors. By analyzing sensor data from turbines and other machinery, GE predicts potential malfunctions before they happen, improving equipment reliability. This predictive approach has led to a reduction in maintenance costs by 10-15% and increased machine availability for critical applications.

2. Generative Design and Optimization

Generative design powered by AI is revolutionizing how engineering companies approach the design process. Instead of manually designing parts or structures, engineers input design goals and constraints into an AI system, which then generates numerous design alternatives. These designs are optimized for performance, material use, and manufacturability, resulting in faster design cycles and more efficient products.

AI-driven generative design uses algorithms like topology optimization and evolutionary design to explore design spaces that would be time-prohibitive for humans to manually investigate. The AI models optimize every element of the design, from shape to material usage, considering factors like weight, strength, and environmental impact. This approach has been widely adopted in aerospace, automotive, and construction industries, where performance and material efficiency are critical.

Tesla uses AI-powered generative design to create lightweight, high-performance vehicle components. By using AI to optimize parts like chassis and brackets, Tesla reduces both material waste and manufacturing time. This approach has led to reduced production costs and a faster time-to-market for new vehicle models.

3. Autonomous Construction Equipment

Autonomous construction equipment is changing the way heavy machinery operates on construction sites. AI-powered machines such as bulldozers, excavators, and cranes use sensors, cameras, and GPS to navigate and perform tasks without human intervention. These machines are designed to increase efficiency, reduce the risk of human error, and enhance safety by operating in hazardous or hard-to-reach areas.

Autonomous construction equipment relies on AI systems that combine computer vision, machine learning, and sensor fusion to understand the environment and make real-time decisions. These systems help the equipment adapt to changing construction site conditions, like uneven terrain or shifting weather patterns. The machines can operate continuously, without needing breaks, which significantly improves project timelines.

Caterpillar has deployed autonomous mining trucks equipped with AI to transport materials without human drivers. The trucks use GPS and sensor data to navigate and deliver materials autonomously, improving safety and productivity on mining sites. This has resulted in a 15% increase in productivity and a 30% reduction in fuel consumption.

4. AI-Driven Quality Control

AI-powered quality control solutions are enhancing the manufacturing and production processes within engineering. Traditional manual inspections are often time-consuming and prone to human error, but AI systems can analyze visual data and identify defects more accurately and rapidly. This technology utilizes computer vision, deep learning, and neural networks to detect defects in materials or products during the production process.

These AI systems can be integrated into production lines, using cameras and sensors to continuously monitor products as they move through the assembly process. The AI models are trained to identify specific types of defects, such as surface cracks, dimensional inconsistencies, or material flaws. Once a defect is detected, the system can trigger automated responses, such as halting the production line or marking a product for further inspection.

BMW employs AI-powered visual inspection systems in its production lines to detect defects in car parts. Using high-resolution cameras and deep learning algorithms, the system inspects thousands of parts during production, ensuring high-quality standards are met. This has resulted in a reduction in defect rates and improved overall product quality.

5. Structural Health Monitoring (SHM)

Structural health monitoring (SHM) involves using AI to continuously monitor the condition of infrastructure such as bridges, buildings, and dams. AI systems process data from sensors embedded in these structures to identify signs of wear, stress, or potential failure. This proactive approach allows engineers to intervene before catastrophic failures occur, ensuring safety and extending the lifespan of critical infrastructure.

Machine learning and data analytics are employed to detect patterns in the sensor data, such as vibrations or stress, that indicate a decline in structural integrity. The AI model can generate real-time alerts, helping engineers to identify specific areas that require maintenance or further inspection. SHM is particularly valuable for aging infrastructure or in locations prone to natural disasters, where early detection can prevent major damage.

The San Francisco-Oakland Bay Bridge uses an AI-powered SHM system to monitor the health of its structure in real-time. Sensors track various indicators, such as vibrations and stress levels, and AI analyzes the data to predict maintenance needs. This system has helped extend the bridge’s lifespan and reduced the risk of unexpected failures.

6. AI-Powered Supply Chain Optimization

AI plays a pivotal role in optimizing supply chain operations, especially in complex engineering industries. AI-driven systems use machine learning algorithms to analyze demand patterns, production schedules, and inventory levels to ensure that materials are sourced and delivered efficiently. By predicting demand fluctuations and optimizing routes, AI can reduce costs, improve delivery timelines, and enhance resource management.

Machine learning models trained on historical data forecast demand, enabling engineers to make better decisions about inventory management, procurement, and production. These AI systems can also detect inefficiencies or bottlenecks in the supply chain, providing actionable insights for process improvement. The strategic benefits include reduced operational costs, more accurate forecasting, and improved customer satisfaction.

Siemens uses AI to optimize its global supply chain, predicting demand fluctuations and adjusting production schedules accordingly. The AI-powered system helps minimize stockouts and ensures more efficient use of resources. This has led to improved lead times and product availability across Siemens’ operations.

Need Expert Help Turning Ideas Into Scalable Products?

Partner with SmartDev to accelerate your software development journey — from MVPs to enterprise systems.

Book a free consultation with our tech experts today.

Let’s Build TogetherExamples of AI in Engineering

In the engineering sector, AI is not just transforming processes but redefining what’s possible. Below are three additional, well-known examples of AI applications that showcase its diverse potential across different engineering domains, from construction to energy to manufacturing.

Real-World Case Studies

1. Bechtel: AI-Powered Construction Project Management

Bechtel, one of the largest construction and engineering companies in the world, has leveraged AI to improve project management efficiency and reduce costs. Construction projects, especially large-scale ones, are notoriously complex, with multiple moving parts, tight deadlines, and risks associated with cost overruns and delays. Bechtel sought a way to streamline its project management and improve its ability to predict potential delays or cost overruns.

By incorporating AI into their project management processes, Bechtel uses machine learning models to analyze historical project data and monitor real-time progress. AI systems track variables like labor, materials, and environmental factors, offering actionable insights to project managers on potential risks. The system also suggests adjustments to ensure projects stay on track. As a result, Bechtel has significantly reduced delays and cost overruns, increasing efficiency across their projects.

Bechtel utilized AI tools to optimize scheduling and resource allocation for major infrastructure projects like the $1.4 billion Qatar Gas Expansion Project. The AI system identified potential delays early, allowing for corrective actions to be taken swiftly. This proactive approach resulted in the successful completion of projects on time and within budget.

2. ArcelorMittal: AI for Steel Production Optimization

ArcelorMittal, the world’s leading steel producer, has integrated AI to optimize the steel manufacturing process, particularly in improving efficiency and quality control. Steel production involves various complex processes, including melting, alloying, and casting, with stringent quality standards that must be met at every step. The company sought to improve its quality control measures and reduce energy consumption in its production plants.

ArcelorMittal applied AI-driven systems to monitor production data and detect anomalies that could affect product quality. By using machine learning algorithms to process real-time data from the production line, AI helps operators identify minor irregularities in the steel and make adjustments instantly. This reduces material waste, increases energy efficiency, and ensures that the steel produced meets the required standards.

ArcelorMittal implemented AI to optimize its production in the steel plant in Ghent, Belgium. The AI system detected variations in the steel quality early on, reducing defects in the final product. This led to a 10% improvement in production efficiency and a reduction in energy consumption, helping ArcelorMittal decrease operational costs while maintaining high-quality output.

3. Shell: AI for Predictive Maintenance in Oil and Gas

Shell, a global leader in the oil and gas industry, has been using AI to improve its operations, particularly in predictive maintenance and optimizing asset management in its offshore drilling platforms. The oil and gas sector is highly dependent on equipment reliability, and unplanned maintenance or system failure can result in costly downtime and environmental risks. Shell sought to implement a system that could predict equipment failure before it happened, reducing maintenance costs and increasing operational efficiency.

Shell uses AI algorithms that analyze sensor data from offshore drilling rigs and other equipment. These algorithms monitor factors like temperature, pressure, and vibration, using historical performance data to predict potential issues with machinery or infrastructure. The AI system can notify operators of potential failures, allowing maintenance to be performed proactively.

Shell implemented AI-powered predictive maintenance at its offshore platforms in the North Sea. By analyzing real-time sensor data, Shell was able to predict mechanical failures in pumps and turbines, resulting in more efficient maintenance scheduling and avoiding unnecessary repairs. This initiative led to a significant reduction in downtime and a 20% decrease in maintenance costs.

Innovative AI Solutions

Emerging AI technologies are driving significant innovation in engineering, enhancing processes such as design, production, and supply chain management. AI-powered generative design is enabling engineers to generate optimized solutions by inputting goals and constraints, vastly improving the speed and efficiency of product development. Similarly, AI-driven robotics are automating tasks like assembly and quality control, increasing precision and reducing human error in manufacturing environments.

AI in supply chain optimization is also revolutionizing logistics, where machine learning algorithms predict demand, optimize routes, and manage inventory in real time. These AI solutions enable companies to reduce costs, improve efficiency, and handle unforeseen disruptions more effectively, ensuring smoother operations and faster delivery times across engineering projects.

AI-Driven Innovations Transforming Engineering

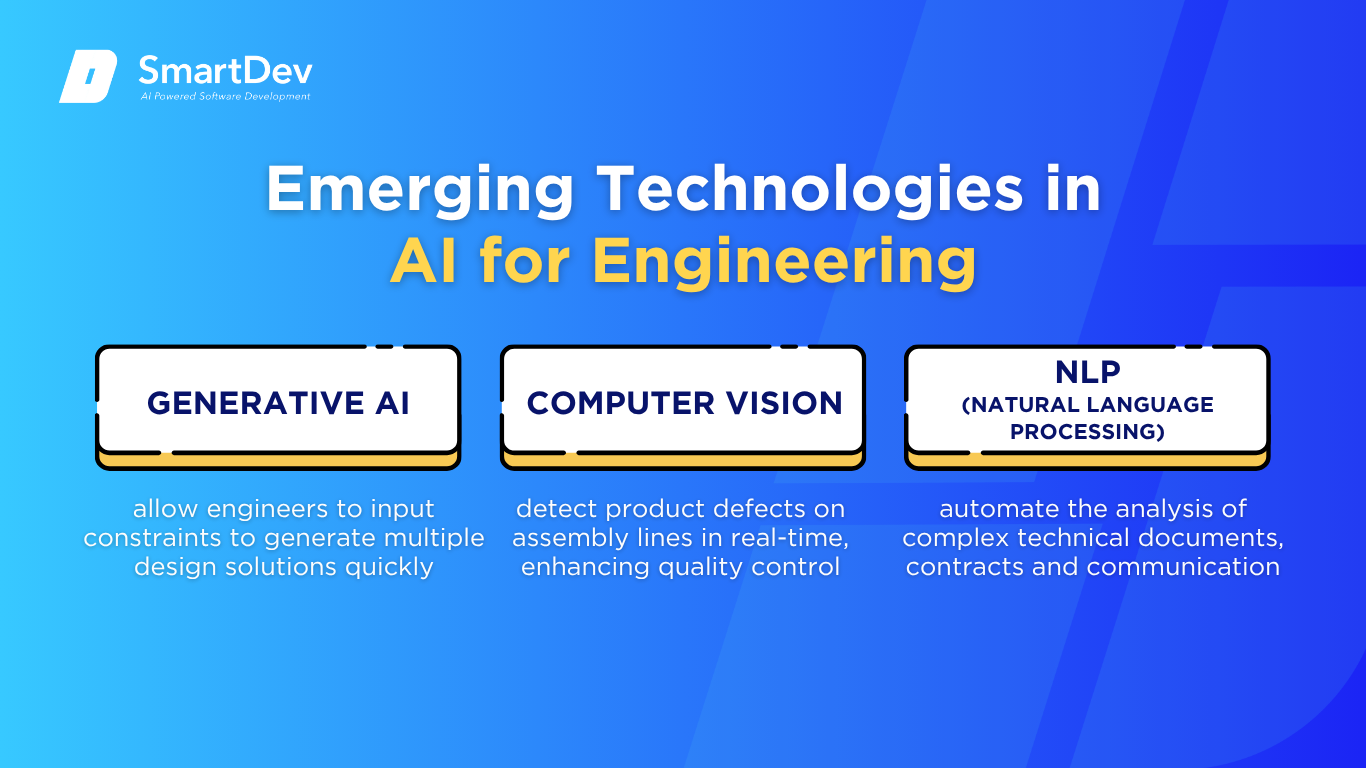

Emerging Technologies in AI for Engineering

AI is reshaping engineering through powerful technologies like generative design and machine learning. Generative AI allows engineers to input constraints like material types and performance criteria to generate multiple design solutions quickly. This approach accelerates design cycles and helps create optimized solutions that might not have been discovered through traditional methods.

Computer Vision also plays a significant role in engineering by enabling machines to “see” and interpret visual data. In manufacturing, AI-powered vision systems detect product defects on assembly lines in real-time, enhancing quality control. Similarly, drones equipped with computer vision are used in construction to monitor project progress, inspect structures, and ensure compliance with safety protocols. This improves both efficiency and accuracy while reducing errors.

Natural Language Processing (NLP) is helping engineers by automating the analysis of complex technical documents, contracts, and communication. This technology extracts relevant information and streamlines processes, allowing engineers to focus on solving technical problems instead of dealing with administrative tasks.

AI’s Role in Sustainability Efforts

AI is supporting sustainability in engineering by improving resource management and reducing waste. Predictive AI tools forecast demand more accurately, helping businesses optimize material use and cut down on overproduction. In manufacturing, AI-powered systems monitor machinery and predict when maintenance is needed, preventing waste due to unexpected breakdowns and keeping production on track.

In construction, AI is used to reduce a building’s environmental impact. Smart systems powered by AI optimize energy consumption in real-time, adjusting heating, cooling, and lighting to reduce overall energy usage. AI also helps in selecting sustainable materials by analyzing their impact on energy efficiency and lifespan, contributing to greener, more sustainable infrastructure.

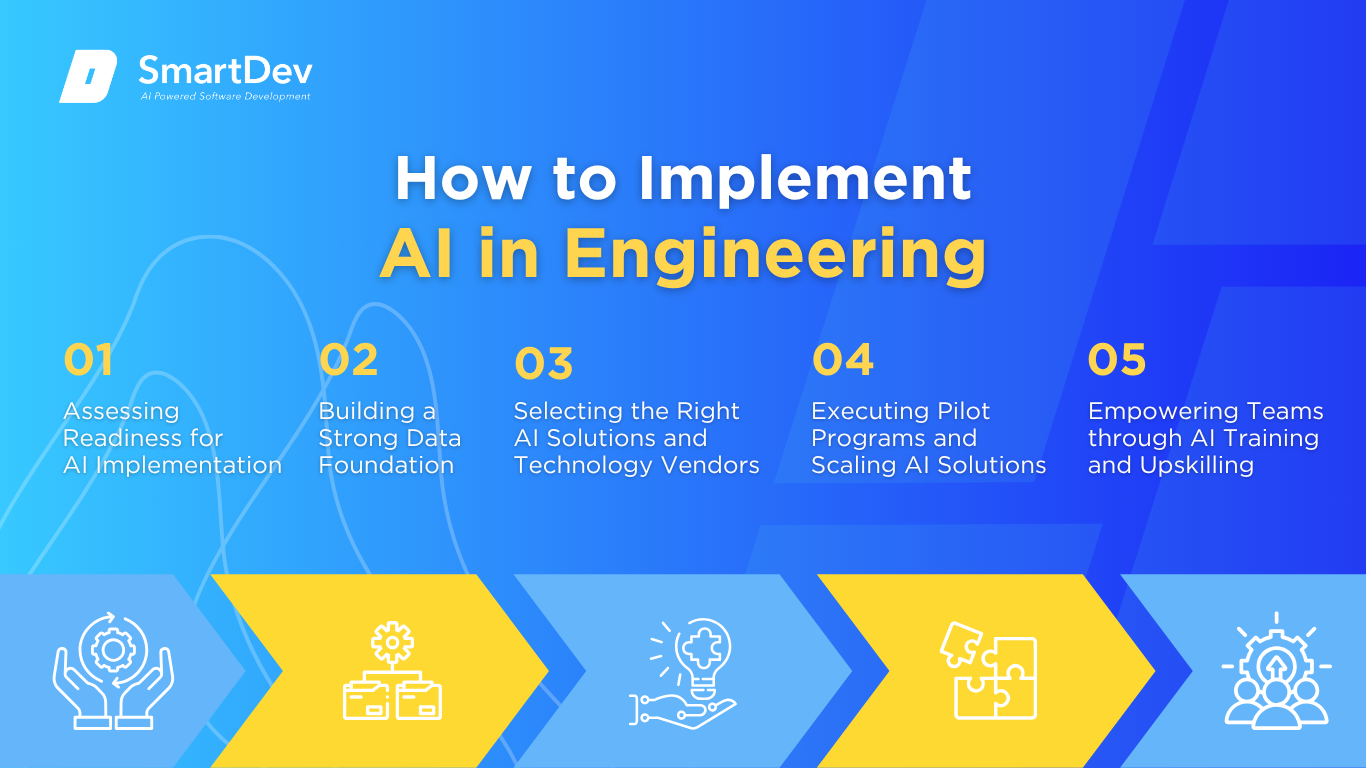

How to Implement AI in Engineering

Step 1: Assessing Readiness for AI Adoption

Before integrating AI, it’s essential to assess readiness. Identify areas where AI can add value, such as automating repetitive tasks or enhancing predictive maintenance. Evaluate your current systems and infrastructure to determine if they support AI, as these tools require high-performance computing and reliable data.

It’s also critical to ensure your team is ready for AI integration. Companies should assess their employees’ technical skills and provide the necessary training to help them adapt to AI tools effectively. This step will help ensure a smooth transition and maximize the impact of AI.

Step 2: Building a Strong Data Foundation

A solid data foundation is crucial for successful AI adoption. Collecting accurate, high-quality data from sources like machinery sensors, production lines, and design models is essential for AI models to generate reliable insights. Ensuring that this data is organized and cleaned is equally important, as AI systems can only make accurate predictions if the data is consistent.

Data security and governance are also key considerations. Protecting your data and ensuring it meets industry regulations will ensure that AI systems can function effectively and compliantly.

Step 3: Choosing the Right Tools and Vendors

When selecting AI tools, ensure they align with your specific engineering needs. Choose platforms that are scalable and integrate well with your existing systems. Look for vendors that have experience in the engineering sector and provide strong customer support to help with integration and troubleshooting.

Work with vendors who understand the unique challenges of engineering to ensure your AI tools are designed to address those challenges. A strong partnership will help ensure you’re getting the most value from your AI solutions.

Step 4: Pilot Testing and Scaling Up

Start with a pilot project to test AI solutions in real-world scenarios. This allows you to assess performance, identify issues, and fine-tune systems before a full-scale deployment. Tracking key metrics during the pilot phase will help you determine the success of the AI integration.

Once the pilot is successful, scaling up becomes easier. Gradually expand AI use across departments, ensuring smooth integration and addressing any issues along the way. This step-by-step approach minimizes risks and ensures that AI is deployed effectively.

Step 5: Training Teams for Successful Implementation

Training is essential for the successful integration of AI. Provide engineers with the skills needed to use AI tools effectively, and ensure they understand how to interpret AI-generated insights. Offering continuous learning opportunities will keep teams up to date on the latest AI developments and foster collaboration between humans and AI systems.

Encouraging a mindset of collaboration between engineers and AI will help ensure the long-term success of AI adoption. This approach helps employees feel more confident and capable of working alongside AI technologies.

Measuring the ROI of AI in Engineering

Key Metrics to Track Success

To measure the ROI of AI in engineering, track productivity improvements, such as time saved through automation and the efficiency gains from predictive maintenance. For instance, AI can help reduce downtime by predicting machinery failures before they happen. Additionally, measuring cost savings from optimized resource usage, energy consumption, and waste reduction will give a clear picture of AI’s impact on your bottom line.

Another critical metric for ROI is error reduction. AI-powered quality control systems continuously monitor production processes, catching defects and inconsistencies early. In engineering, even small defects can lead to costly repairs, delays, or failures. AI ensures these issues are identified and addressed before they escalate, reducing the need for rework or costly repairs. As a result, AI not only minimizes errors but also builds greater trust with clients, driving long-term value through higher-quality deliverables and more satisfied customers.

Case Studies Demonstrating ROI

A telecommunications firm implemented AI-based sentiment analysis and chat support to reduce customer churn. Within six months, response times fell by 40%, and customer satisfaction rose by 25%, leading to measurable retention improvements. The solution centralized insights and allowed agents to focus on complex escalations.

An international apparel brand deployed AI recommendation engines on its e-commerce site to guide shoppers based on real-time browsing and purchase data. This resulted in a 35% increase in average order value and a 28% boost in conversion rates. Personalization based on AI-driven insights helped streamline the buying journey and improve customer loyalty.

Common Pitfalls and How to Avoid Them

One common pitfall in AI adoption is underestimating the complexity of implementation. It’s crucial to have a clear strategy and realistic expectations about what AI can achieve. Don’t rush into adoption without fully understanding the technical requirements and challenges involved.

Another issue is neglecting employee buy-in. If employees feel threatened by AI or aren’t properly trained, the technology won’t be embraced. Providing thorough training and fostering a collaborative environment between AI systems and engineers is essential for long-term success.

Future Trends of AI in Engineering

Predictions for the Next Decade

Looking ahead, AI will continue to shape the future of engineering. In the next decade, expect a deeper integration of AI in design, manufacturing, and operations. AI-powered robots will play a significant role in automating complex tasks, especially in high-risk or hazardous environments. The rise of autonomous systems, particularly in construction and heavy industry, will redefine how engineering projects are managed and executed.

Additionally, advancements in AI algorithms will lead to more personalized and adaptive engineering processes. Engineers will be able to use AI to create highly tailored solutions that meet specific client needs while optimizing for efficiency and sustainability. With the continued growth of AI, the engineering industry will become increasingly data-driven, with real-time analytics driving decision-making across all phases of projects.

How Businesses Can Stay Ahead of the Curve

To stay ahead, engineering companies must foster a culture of continuous learning and innovation. Embrace emerging technologies early, invest in AI research and development, and keep teams updated on the latest advancements in AI. Collaborating with AI startups, universities, and research organizations will give businesses access to cutting-edge technologies and help them remain competitive.

Furthermore, it’s essential to adopt a flexible approach to AI integration. As AI evolves, new tools and technologies will emerge, offering even greater potential for optimization. By staying agile and adaptable, engineering companies can future-proof their operations and continue to reap the benefits of AI well into the future.

Conclusion

Key Takeaways

AI is revolutionizing the engineering industry by enhancing productivity, improving design processes, and reducing operational costs. From predictive maintenance and generative design to AI-powered quality control, AI technologies are transforming how engineering companies approach their projects.

By integrating AI into their operations, businesses can achieve greater efficiency, sustainability, and cost-effectiveness. Companies that invest in the right tools, data management practices, and employee training will reap the rewards of AI, ensuring long-term growth and innovation.

Emerging AI technologies, such as advanced machine learning algorithms and autonomous systems, will continue to shape the future of engineering. Those who embrace these innovations early, focus on strategic implementation, and collaborate with technology partners will maintain a competitive edge and set new standards for operational excellence in the years ahead.

Moving Forward: A Strategic Approach to AI in Engineering

If your organization is ready to harness the power of AI in engineering, now is the time to act strategically. Begin by assessing your current engineering processes and identifying areas where AI can provide the most value, whether in design optimization, predictive maintenance, or resource management. Collaborate with AI experts to ensure that you’re choosing the right solutions and effectively integrating them into your existing systems.

By partnering SmartDev, you can minimize implementation risks and speed up the time-to-value through expert advice and tailored strategies. Don’t wait for your competitors to take the lead, embrace AI now to enhance productivity, improve quality, and achieve greater operational efficiency.

Reach out to us to explore AI-driven solutions designed specifically for engineering transformation. Together, we’ll help you create scalable, data-driven strategies that drive measurable impact and position your business as a leader in innovation.

—

References:

- Aerospace and Defense Industry Outlook | Deloitte

- State of Design and Make Report: Growing Confidence in Resilience and AI | Autodesk

- The State of AI | McKinsey

- Artificial Intelligence in Engineering | National Academy of Engineering

- How GE Uses AI to Implement Predictive Maintenance | Redress Compliance

- Challenges in Generative Design for Automotive EV Industry | Neural Concept

- Tesla AI | Tesla

- Caterpillar Bets on Self-Driving Machines | Reuters

- Artificial Intelligence in BMW Group Production | BMW Group Press

- How Siemens Utilizes AI to Optimize Supply Chain Management | Redress Compliance