Introduction

Logistics is evolving at an unprecedented pace, driven by increasing global supply chain complexity and rising customer expectations. To stay competitive, the industry is adopting artificial intelligence—a transformative technology that goes well beyond automation. AI is reshaping how logistics companies analyze data, predict trends, manage resources, and innovate operational models. Emerging use cases in logistics demonstrate how AI enables businesses to operate with greater agility and efficiency.

What is AI and Why Does It Matter in Logistics?

Definition of AI and Its Core Technologies

Artificial Intelligence (AI) refers to computer systems capable of performing tasks traditionally requiring human intelligence, such as learning, reasoning, and decision-making. Core AI technologies include machine learning (ML), natural language processing (NLP), and computer vision, enabling machines to analyze data, recognize patterns, and make predictions or decisions autonomously. According to IBM, AI involves a suite of technologies designed to sense, comprehend, act, and learn with human-like intelligence.

In logistics, AI applies these technologies to optimize complex operations, from demand forecasting and route planning to warehouse automation and real-time supply chain monitoring. By integrating AI, logistics companies can manage vast data streams, enhance operational precision, and adapt swiftly to disruptions, transforming traditional supply chains into intelligent networks.

The Growing Role of AI in Transforming Logistics

AI is rapidly changing logistics operations. Automated warehouses powered by robotics and AI-driven inventory management systems improve speed and accuracy while reducing errors and labor costs. Intelligent route optimization models analyze traffic, weather, and delivery windows to minimize fuel consumption and enhance on-time deliveries. Additionally, AI-enabled predictive analytics anticipates demand fluctuations, allowing proactive adjustments in inventory and transport resources.

Modern logistics also relies on AI for real-time visibility and risk mitigation. AI-driven platforms aggregate data from IoT sensors, GPS, and external sources to monitor shipment conditions and predict disruptions. This enables logistics managers to make informed decisions and communicate proactively with customers. Companies adopting AI see improvements not only in efficiency but also in customer satisfaction and competitive agility.

Key Statistics and Trends Highlighting AI Adoption in Logistics

AI adoption in logistics is accelerating. A 2024 Gartner report estimates that 70% of logistics providers will implement AI-driven solutions by 2026 to enhance supply chain resilience and reduce costs. Research by McKinsey highlights that AI can lower logistics operational expenses by up to 15%, while boosting delivery speed and accuracy. The global AI in logistics market is projected to grow at a compound annual growth rate (CAGR) of 35% from 2023 to 2030, reflecting strong demand for intelligent automation and analytics.

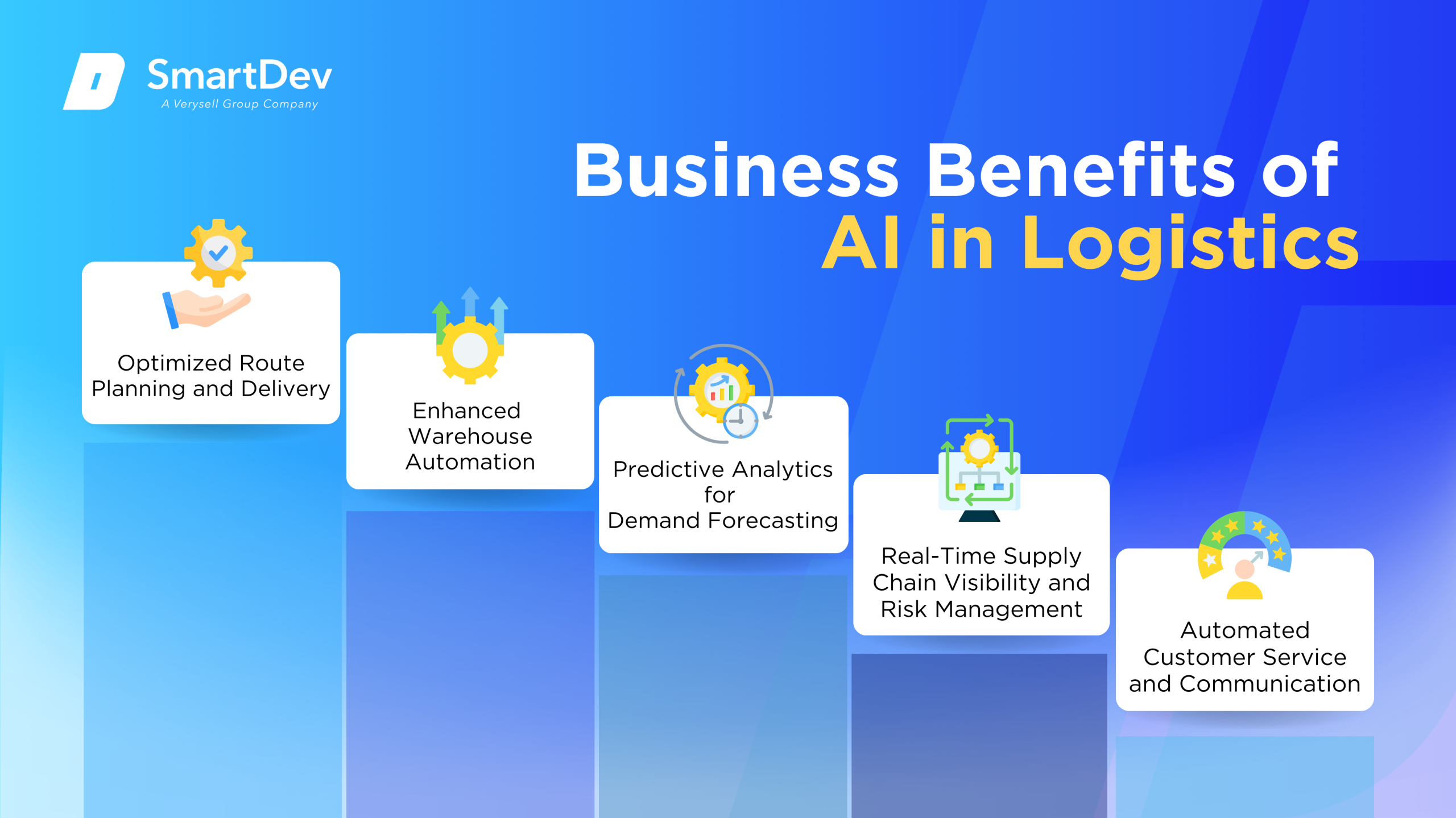

Business Benefits of AI in Logistics

AI tackles fundamental challenges in logistics by streamlining operations, lowering costs, and enhancing supply chain visibility. These improvements translate into measurable business value, enabling companies to operate more efficiently and respond faster to market demands.

1. Optimized Route Planning and Delivery

AI algorithms analyze traffic conditions, weather patterns, delivery windows, and vehicle capacities to design optimal routes that reduce fuel consumption and improve delivery times. Unlike traditional route planning, which struggles to incorporate multiple dynamic variables in real time, AI continuously adapts to changing conditions for maximum efficiency.

This capability lowers operational costs and carbon emissions while boosting customer satisfaction through more reliable deliveries.

2. Enhanced Warehouse Automation

Robotics combined with AI-powered vision systems automate picking, packing, and sorting processes in warehouses, reducing errors and labor costs. AI-driven inventory management predicts stock needs based on demand patterns and supply variability, preventing overstocking or stockouts.

This improves warehouse throughput and accuracy, enabling logistics providers to handle fluctuating demand efficiently.

3. Predictive Analytics for Demand Forecasting

AI leverages historical sales data, seasonality, market trends, and external factors to predict demand fluctuations with high accuracy. This insight allows logistics planners to optimize inventory levels, workforce allocation, and transportation resources proactively.

Accurate forecasting mitigates risks related to delays, shortages, or excess inventory.

4. Real-Time Supply Chain Visibility and Risk Management

AI platforms aggregate data from IoT sensors, GPS trackers, weather forecasts, and news sources to deliver real-time shipment tracking and risk alerts. This comprehensive visibility enables logistics managers to detect potential delays, damaged goods, or security threats before they escalate.

Proactive interventions facilitated by AI minimize disruptions, reduce costs linked to delays, and increase transparency for customers.

To see how AI-powered solutions can improve real-time visibility and traceability in logistics, check out our case study on building a secure, automated track & trace system.

5. Automated Customer Service and Communication

Natural Language Processing (NLP) powers AI chatbots and virtual assistants that handle routine customer inquiries, track shipments, and provide updates 24/7. These tools free human agents to address complex issues, improving response times and customer experience.

AI-enabled sentiment analysis also helps logistics providers gauge customer satisfaction and identify pain points for continuous service improvement.

Learn how AI enhances efficiency and productivity in real-world operations in our detailed guide on unlocking operational efficiency with AI.

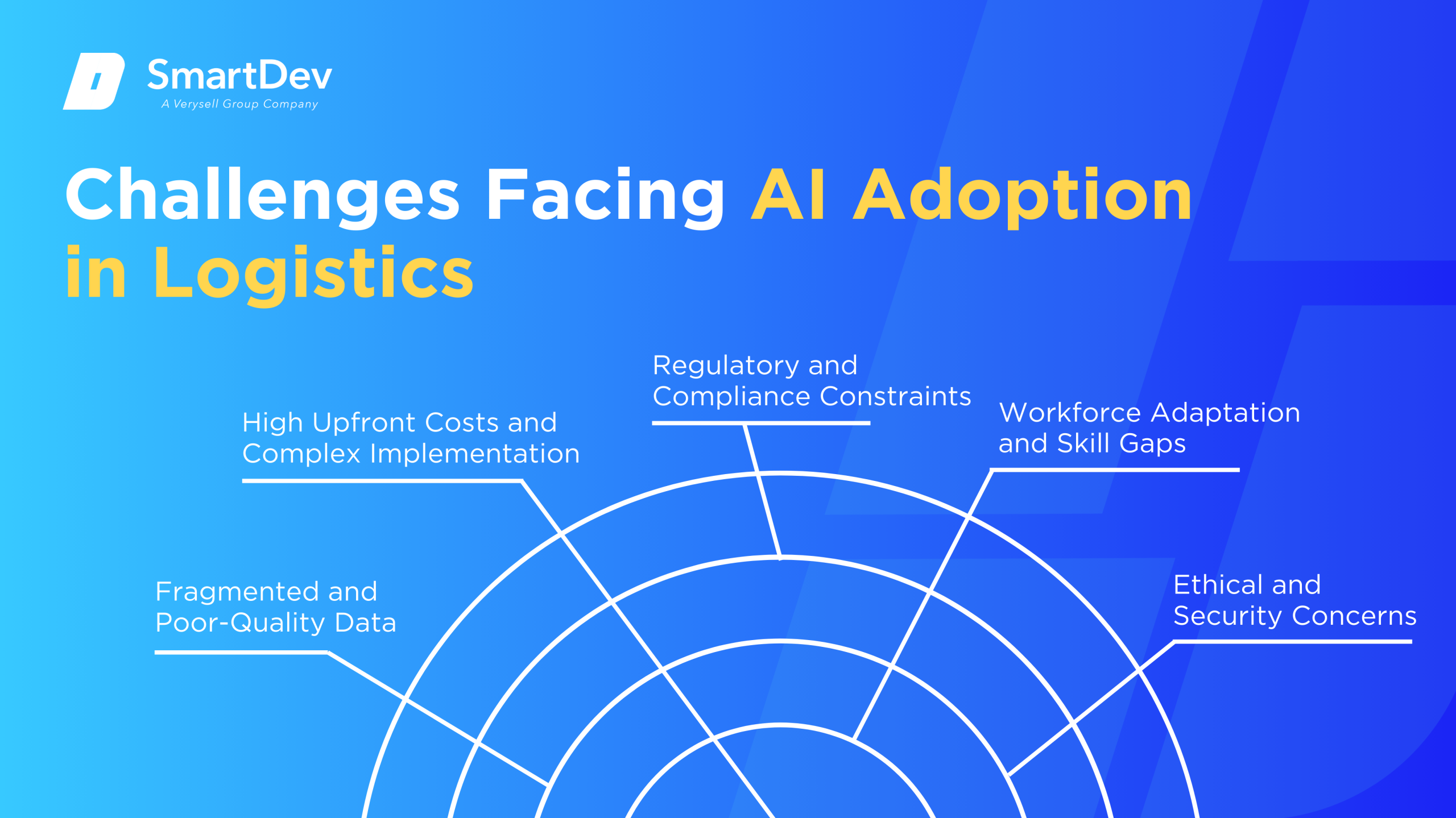

Challenges Facing AI Adoption in Logistics

While AI brings powerful capabilities to logistics, its implementation is often met with significant barriers. Issues like data fragmentation, high costs, and regulatory constraints can delay progress and reduce the impact of AI initiatives.

1. Fragmented and Poor-Quality Data

Logistics data often reside in disparate systems—transportation management, warehouse management, customer service—making integration difficult. Poor data quality and inconsistent formats undermine AI models’ accuracy and reliability.

Unifying these data silos requires significant investment in IT infrastructure, standardization, and ongoing governance, often slowing AI deployments.

2. High Upfront Costs and Complex Implementation

Deploying AI solutions, especially robotics or advanced analytics platforms, demands substantial capital expenditure and skilled personnel. Smaller logistics firms may struggle to justify or manage such investments without clear short-term ROI.

Additionally, integrating AI into existing legacy systems involves complex change management and can disrupt operations during the transition.

3. Regulatory and Compliance Constraints

Logistics is subject to numerous regulations concerning data privacy, cross-border shipments, and safety standards. AI systems must comply with these evolving regulations, adding complexity to solution design and deployment.

Non-compliance risks legal penalties and damages reputation, making firms cautious in AI adoption without robust governance frameworks.

4. Workforce Adaptation and Skill Gaps

AI automation shifts workforce roles, requiring new technical skills in data analysis, AI maintenance, and oversight. Logistics companies must invest in training and change management to reskill staff.

Resistance may arise if employees fear job displacement or lack understanding of AI benefits, impacting adoption speed.

5. Ethical and Security Concerns

AI systems rely heavily on data, raising concerns about data security, misuse, and algorithmic bias. Logistics companies must balance AI innovation with stringent data privacy and security requirements, avoiding legal risks and reputational damage.

Moreover, ensuring transparency in AI decision-making and addressing potential biases is critical to maintaining stakeholder trust and meeting ethical standards in logistics operations.

Specific Applications of AI in Logistics

1. Route Optimization and Transportation Management

Route optimization is a critical challenge in logistics, where inefficiencies translate directly into higher costs and longer delivery times. AI-powered route optimization leverages machine learning algorithms and real-time data to calculate the most efficient paths for fleets, considering factors like traffic, weather, vehicle capacity, and delivery windows. This reduces fuel consumption, speeds up deliveries, and improves overall fleet utilization.

The process typically uses predictive analytics and reinforcement learning models to continuously improve routing decisions based on historical and live data inputs. Data such as GPS coordinates, traffic sensor feeds, and customer orders feed into AI systems integrated with fleet management platforms, enabling dynamic route adjustments. This integration allows logistics providers to respond swiftly to disruptions, such as accidents or delays, maintaining delivery reliability.

The strategic value of AI route optimization lies in cost reduction and enhanced customer satisfaction. By minimizing mileage and travel time, companies can significantly cut operational expenses while meeting tighter delivery schedules. However, challenges such as data privacy and system scalability must be addressed, particularly when integrating with third-party navigation systems and diverse vehicle fleets.

Real-World Example:

DHL uses AI-based route optimization tools to streamline last-mile deliveries. By employing AI algorithms, DHL reported a reduction in delivery times by up to 20% and a notable decrease in fuel consumption, contributing to sustainability goals. Their platform incorporates traffic data and predictive models to reroute vehicles in real-time, optimizing resource allocation and improving customer experience.

2. Predictive Maintenance for Fleet Management

Unplanned vehicle breakdowns can cause costly delays and disrupt supply chains. Predictive maintenance uses AI to forecast when a vehicle or equipment will require servicing based on sensor data and historical maintenance records. This proactive approach helps logistics companies schedule maintenance efficiently, avoiding unexpected downtime.

AI models analyze data from IoT sensors monitoring engine performance, brake wear, tire pressure, and other critical parameters. Machine learning algorithms detect anomalies and predict failure patterns by comparing current data with historical benchmarks. This integration with fleet management systems enables automated alerts and optimized maintenance schedules.

The operational benefits include improved asset uptime, reduced maintenance costs, and extended equipment lifespan. Predictive maintenance also enhances safety by preventing catastrophic failures. However, deploying IoT infrastructure and ensuring data security are key technical considerations for large logistics networks.

Real-World Example:

UPS, for instance, has implemented predictive maintenance powered by AI across its delivery trucks. Their system analyzes vehicle sensor data to predict mechanical issues before failures occur, resulting in a 15% reduction in breakdowns and significant savings in maintenance costs. This AI-driven approach also supports UPS’s commitment to reliable and timely deliveries worldwide.

3. Warehouse Automation and Robotics

Warehouses are pivotal in logistics, where efficiency and accuracy determine overall supply chain performance. AI-driven warehouse automation combines robotics, computer vision, and machine learning to streamline inventory management, order picking, and packaging. This reduces human error and accelerates throughput.

AI-powered robots navigate warehouse floors using vision systems and spatial mapping, dynamically adjusting to changing inventory locations and operational demands. Machine learning algorithms forecast demand patterns and optimize stock placement for quicker retrieval. Integrating these systems with warehouse management software creates a seamless workflow from inventory receipt to dispatch.

Operational gains include faster order fulfillment, lower labor costs, and improved inventory accuracy. Ethical considerations arise around workforce displacement, necessitating thoughtful implementation strategies to balance automation with human roles. Data integrity and system interoperability are also vital to maintain smooth operations.

Real-World Example:

Amazon Robotics exemplifies this use case with its extensive deployment of AI-guided robots in fulfillment centers. These robots move shelves to human pickers, reducing travel time and increasing order processing speed. Amazon reports a 20% increase in warehouse productivity, enabling faster delivery times and handling peak season surges efficiently.

4. Demand Forecasting and Inventory Optimization

Accurate demand forecasting is essential for logistics to minimize stockouts and excess inventory. AI enhances forecasting by analyzing vast datasets, including historical sales, market trends, weather conditions, and social media signals. This enables logistics companies to predict product demand with higher precision.

Machine learning models process structured and unstructured data to identify patterns and correlations that traditional methods might miss. These forecasts integrate with inventory management systems to automate replenishment decisions and adjust safety stock levels dynamically. This alignment ensures that warehouses maintain optimal inventory levels tailored to fluctuating demand.

The strategic value lies in reducing holding costs, avoiding lost sales, and improving cash flow. However, challenges include data quality, model transparency, and adapting to sudden market disruptions such as global crises. Ethical AI use demands vigilance to avoid reinforcing biases present in historical data.

Real-World Example:

Maersk, a global logistics leader, employs AI-driven demand forecasting to optimize its container inventory across ports and terminals. By incorporating AI predictions, Maersk improved inventory turnover rates and reduced excess stock, resulting in cost savings and increased responsiveness to market demand fluctuations.

5. Intelligent Document Processing (IDP)

Logistics involves extensive paperwork, including invoices, bills of lading, customs forms, and delivery receipts. Intelligent Document Processing (IDP) leverages AI technologies like optical character recognition (OCR), natural language processing (NLP), and machine learning to automate the extraction, classification, and validation of data from these documents. This reduces manual effort and errors. IDP systems scan and interpret a wide variety of document formats, extracting key information and integrating it into enterprise resource planning (ERP) or transportation management systems (TMS). Machine learning models improve accuracy over time by learning from human corrections and new document types. Automation accelerates processing times and enhances data reliability.

The operational advantage is faster invoicing, improved compliance, and enhanced transparency across logistics workflows. Data security and privacy are paramount, especially when handling sensitive customs and financial information. Scalability challenges arise with the diverse document types and languages in global logistics.

Real-World Example:

FedEx has implemented IDP solutions to automate invoice processing and customs documentation. Using AI platforms, FedEx reduced manual processing time by 70%, increased data accuracy, and accelerated customs clearance, resulting in smoother cross-border shipments and better customer satisfaction.

6. Supply Chain Risk Management

Supply chain disruptions, whether from geopolitical events, natural disasters, or supplier failures, can severely impact logistics operations. AI-powered risk management tools analyze diverse data sources to identify vulnerabilities and forecast potential disruptions in the supply chain. This enables proactive mitigation strategies.

These tools use machine learning models to monitor supplier performance, geopolitical news, weather patterns, and transportation conditions. AI integrates this data with existing supply chain management platforms, providing real-time risk alerts and scenario simulations. Decision-makers gain actionable insights to reroute shipments or source alternative suppliers promptly.

The strategic benefit is enhanced resilience, reduced downtime, and improved risk response times. Ethical considerations include transparency in AI-driven decisions and avoiding bias that may unfairly affect suppliers or regions. Maintaining updated and accurate data inputs is crucial for reliability.

Real-World Example:

IBM’s Supply Chain Insights platform uses AI to help logistics providers anticipate and manage risks. By analyzing global data, IBM clients have reduced disruption-related delays by 30% and improved supply chain visibility, allowing for more agile and informed decision-making.

Examples of AI in Logistics

Real-World Case Studies

Moving beyond individual AI applications, real-world examples in logistics demonstrate the tangible impact of AI technologies. These case studies highlight how AI is reshaping logistics by delivering significant efficiency gains and operational improvements.

1. Amazon: AI-Driven Supply Chain Optimization

Amazon employs AI across its supply chain to enhance efficiency and customer satisfaction. The company utilizes AI for demand forecasting, warehouse automation, and dynamic route planning.

By integrating AI into its operations, Amazon has achieved faster delivery times, reduced operational costs, and improved inventory management. The use of AI-driven robots in warehouses has significantly increased order fulfillment speed.

2. Uber Freight: Optimizing Truck Routes

Uber Freight leverages AI to optimize truck routing and reduce inefficiencies in the freight industry. The platform uses machine learning algorithms to match truckers with continuous loads, minimizing empty miles.

Since its launch, Uber Freight has managed over $20 billion in freight and served numerous Fortune 500 companies. The AI-driven system has helped reduce empty miles by 10–15%, enhancing operational efficiency.

3. Port of Corpus Christi: AI-Powered Digital Twin

The Port of Corpus Christi implemented an AI-powered digital replica system called OPTICS to improve real-time tracking and safety. The system creates a digital twin of the port using live and historical data for effective oversight.

OPTICS employs machine learning to predict ship positions and generative AI for emergency response training. This has enhanced navigation safety and emergency preparedness at the port.

Innovative AI Solutions

The logistics industry is continuously evolving with emerging AI technologies that push the boundaries of operational excellence. Innovations such as autonomous delivery vehicles, blockchain-integrated AI for secure transactions, and advanced computer vision for real-time package tracking are gaining traction. These technologies promise to redefine logistics workflows, making them more autonomous, transparent, and efficient.

Learn how the fusion of AI and blockchain is reshaping logistics with greater trust and traceability in our guide on integrating AI with blockchain technology.

For example, autonomous drones and self-driving trucks powered by AI are beginning pilot deployments, aiming to reduce labor costs and expedite deliveries in challenging environments. Blockchain combined with AI ensures secure and immutable shipment records, enhancing trust among supply chain partners. These innovations signal a future where AI’s role in logistics expands beyond optimization to reshaping the entire ecosystem.

AI-Driven Innovations Transforming Logistics

Emerging Technologies in AI for Logistics

Artificial Intelligence (AI) is revolutionizing logistics by introducing technologies like digital twins that enhance real-time visibility and operational safety. These AI-powered replicas use live and historical data to fill tracking gaps, predict movement with precision, and support safer navigation across supply chains. Generative AI also plays a key role in training scenarios, enabling realistic simulations that prepare teams for emergency situations.

Computer vision is another transformative AI tool in logistics, particularly within warehouse and yard environments. By analyzing visual data in real time, it helps identify inefficiencies, improve ergonomics, and enhance overall workplace safety. Heatmap analysis generated through computer vision enables smarter layout planning, reducing bottlenecks and optimizing resource placement.

AI’s Role in Sustainability Efforts

AI helps reduce waste by improving demand forecasting accuracy, which lowers overproduction and excess inventory. This leads to more efficient resource use and less environmental impact. Additionally, AI-powered smart systems optimize energy consumption in warehouses and transport fleets, cutting carbon emissions.

By analyzing real-time data, AI adjusts lighting, heating, and route plans to save energy and costs. This not only benefits the environment but also improves operational profitability. Sustainability efforts driven by AI position logistics companies as responsible and forward-thinking.

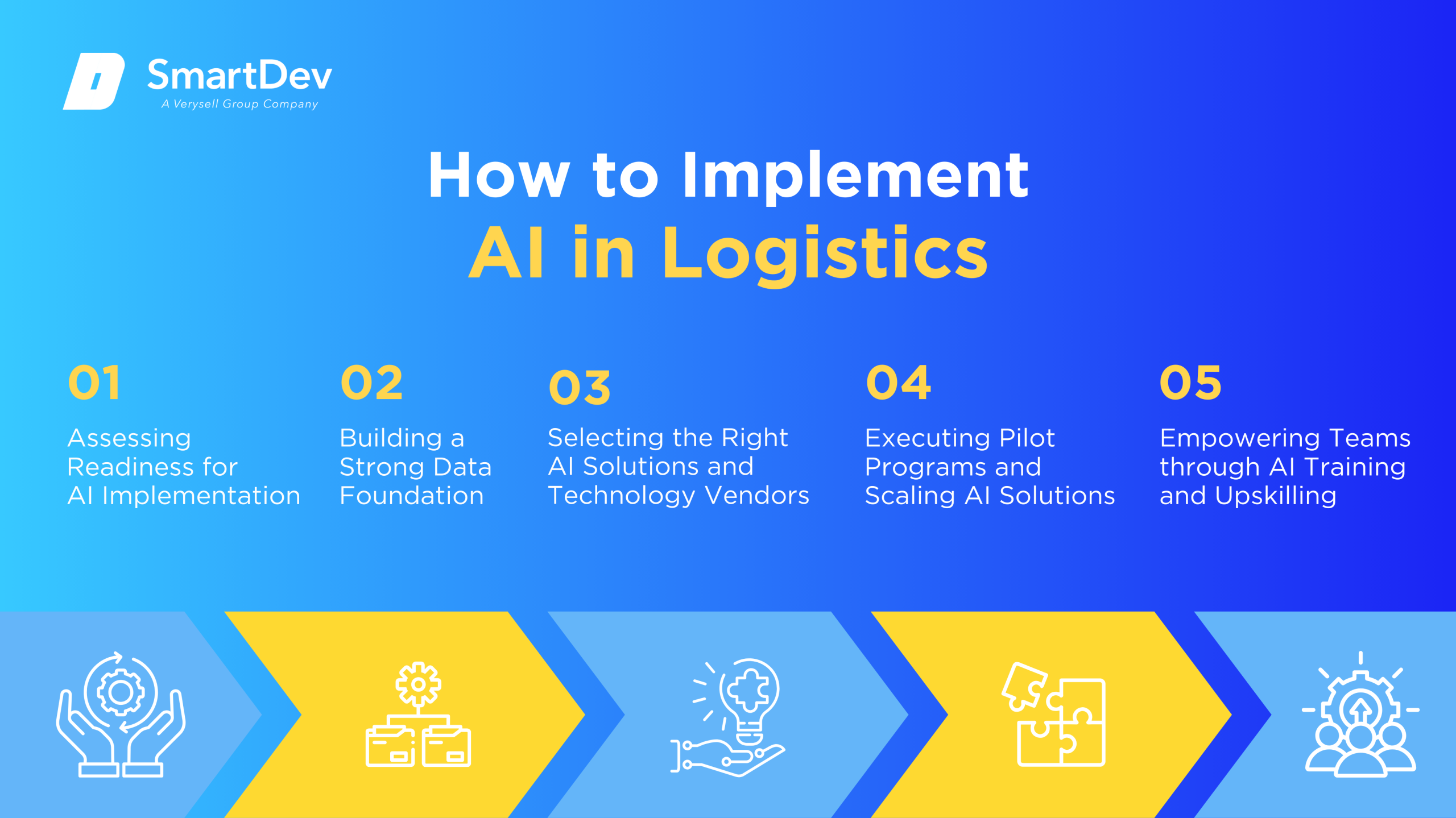

How to Implement AI in Logistics

Step 1. Assessing Readiness for AI Adoption

Before you implement AI, it’s vital to evaluate your current capabilities and pinpoint where AI can truly add value. This means assessing the quality of your data, the strength of your technological infrastructure, and your team’s readiness to embrace new tools. For instance, ensure you have reliable data collection processes, and a workforce equipped to manage and interpret AI-driven insights.

Step 2. Building a Strong Data Foundation

AI thrives on quality data, so establishing a robust data foundation is non-negotiable. This involves gathering accurate, relevant data from across your logistics operations, cleaning it to eliminate errors and inconsistencies, and managing it within a centralized system. With well-prepared data, your AI models can generate precise predictions and actionable insights that drive smarter decisions.

Step 3. Choosing the Right Tools and Vendors

Selecting the right AI platforms and partners plays a critical role in your success. Evaluate options based on how well they align with your specific logistics needs, their scalability, and compatibility with your existing systems. Partnering with vendors who have deep logistics expertise can offer tailored support and smoother integration.

Step 4. Pilot Testing and Scaling Up

Start your AI journey with small pilot projects to validate the technology’s impact and work out any kinks. These focused trials help uncover challenges early, giving you room to refine your approach before wider adoption. Once pilots prove successful, you can confidently scale AI solutions across your operations for maximum effect.

Step 5. Training Teams for Successful Implementation

Your investment in AI will only pay off if your people are ready to work alongside it. Provide targeted training that equips employees with the skills to use AI tools, analyze data, and make informed decisions. Encouraging ongoing learning keeps your workforce agile and prepared for continuous AI advancements.

Measuring the ROI of AI in Logistics

Key Metrics to Track Success

To accurately evaluate the return on investment of AI in logistics, it is essential to monitor productivity improvements as a primary metric. AI streamlines and automates complex, time-intensive tasks, thereby increasing operational throughput and reducing the incidence of human error. Quantifying these enhancements in efficiency provides a clear measure of AI’s contribution to overall business performance.

Equally important is the measurement of cost savings resulting from AI deployment. By automating routine processes, optimizing asset utilization, and minimizing waste, AI drives significant reductions in operational expenditures. Analyzing the balance between implementation costs and realized savings enables organizations to assess the financial viability and long-term benefits of their AI investments.

Case Studies Demonstrating ROI

Real-world case studies offer tangible proof of AI’s ROI in operations. For instance, Amazon’s extensive use of AI-driven robotics in its warehouses has significantly lowered order fulfillment costs. By deploying over 750,000 mobile robots, the company has improved efficiency and expects to save billions annually by 2030. This investment showcases how AI can scale operations while reducing expenses.

Similarly, Uber Freight leverages AI to optimize truck routing, cutting down on empty miles by 10 to 15 percent. This improvement not only reduces fuel consumption but also enhances delivery speed and customer satisfaction. Their success illustrates how AI-driven logistics can create both environmental and financial value.

Common Pitfalls and How to Avoid Them

While AI offers significant benefits for logistics, organizations often fall into common traps that hinder success. One major pitfall is relying too heavily on AI without sufficient human oversight. Balancing AI automation with expert human judgment is essential to manage complex decisions and unexpected challenges effectively.

Another frequent issue is implementing AI without clear alignment to business goals. To maximize ROI, AI solutions must directly support objectives such as cost reduction, quality improvement, or enhanced supply chain visibility. Establishing clear communication and a well-defined strategy ensures AI initiatives deliver measurable and lasting value.

Future Trends of AI in Logistics

Predictions for the Next Decade

Over the next decade, AI is poised to transform supply chains into largely autonomous systems. These smart supply chains will self-configure, optimize operations, and even self-heal with minimal human involvement. This shift promises to increase efficiency while reducing operational risks.

AI’s predictive capabilities are also expected to advance significantly, delivering more precise and actionable forecasts. Businesses will be able to anticipate market fluctuations and adjust their strategies with greater agility. This proactive approach will help companies stay competitive in an increasingly dynamic environment.

Additionally, AI-powered robotics will expand beyond traditional warehouse automation. Autonomous vehicles will become more prevalent in transportation and last-mile delivery, enhancing speed and reliability. The integration of these technologies will further streamline logistics operations and reduce costs.

How Businesses Can Stay Ahead of the Curve

To remain at the forefront of the logistics industry, businesses must prioritize sustained investment in research and development to continuously monitor and adopt emerging AI technologies. Such a strategic focus ensures access to innovative solutions that enhance operational efficiency and competitive advantage. Cultivating a culture that encourages creativity, and experimentation further enables the identification and implementation of novel AI applications.

Moreover, forming strategic partnerships with industry leaders and AI specialists provides critical expertise and accelerates technology integration. Collaborating with experienced vendors facilitates smoother adoption and optimizes the impact of AI initiatives. By employing these approaches, organizations can position themselves as leaders in the evolving landscape of AI-driven logistics.

Conclusion

Key Takeaways

AI is revolutionizing logistics by driving efficiency, agility, and resilience across the supply chain. Through advanced automation, predictive analytics, and intelligent optimization, logistics companies can reduce costs, accelerate delivery times, and improve transparency. Moreover, AI’s role in enhancing sustainability and risk management positions the industry for long-term growth amid evolving market challenges.

To succeed in this dynamic landscape, logistics businesses must adopt a strategic, data-driven approach to AI: building robust data foundations, piloting targeted solutions, and investing in workforce training. Embracing these principles will enable organizations to harness AI’s full potential and maintain a competitive edge.

Moving Forward: A Path to Progress

As AI advances, the logistics industry has a unique opportunity to boost efficiency, cut costs, and strengthen supply chain resilience. To stay ahead, logistics companies must strategically adopt AI and foster continuous innovation. Building strong data foundations and integrating AI into core operations enables smarter routing, better forecasting, and streamlined warehouse management.

At SmartDev, we specialize in delivering tailored AI solutions that transform logistics operations and deliver measurable results. Whether optimizing routes, automating warehouses, or enabling predictive maintenance, our expert team helps you unlock new efficiencies and adapt swiftly to market demands.

Contact us today to discover how AI can elevate your capabilities, optimize resource utilization, and position your business for sustainable growth. Partner with us to build a smarter, more agile future powered by the latest AI innovations.

—

References:

- What is artificial intelligence (AI)? | IBM

- The True Role Of AI In Logistics | Forbes

- Supply chain trends 2024: The digital shake-up | KPMG

- Succeeding in the AI supply-chain revolution | McKinsey & Company

- AI in Logistics and Supply Chain Management | SSRN Electronic Journal

- AI in Logistics and Last-Mile Delivery | DHL

- Top 8 Gen AI Use Cases in Logistics | Medium

- How UPS Uses AI to Predict Maintenance Needs for Its Delivery Fleet | Redress Compliance

- Amazon unveils the next generation of fulfillment centers powered by AI and 10 times more robotics | Amazon

- Eye on the future – AI in supply chains and logistics | Maersk