Introduction

Product Lifecycle Management (PLM) lies at the heart of innovation – and yet many organizations struggle with siloed data, sluggish development cycles, and escalating complexity across product lifespans. AI is proving to be a game-changer, streamlining workflows, accelerating design, and enabling smarter decision-making across PLM. This guide explores how AI is transforming PLM across industries, from automating routine tasks to powering predictive insights and generative design.

What is AI and Why Does It Matter in PLM?

Definition of AI and Its Core Technologies

Artificial Intelligence enables machines to perform tasks that typically require human intelligence, such as learning, reasoning, and decision-making. It relies on technologies like machine learning, natural language processing, computer vision, and generative AI. These tools allow systems to process data, identify patterns, and automate complex decisions.

In the context of PLM (Product Lifecycle Management), AI helps automate labor-intensive tasks and interpret vast volumes of engineering and operational data. It enables smarter collaboration across teams by linking design, manufacturing, and supply chain insights. This leads to faster development cycles, fewer errors, and stronger alignment between product design and business strategy.

The Growing Role of AI in Transforming PLM

AI is becoming a critical driver in how organizations manage the product lifecycle, from initial concept through end-of-life. It enables teams to analyze complex datasets, automate time-consuming processes, and generate insights that support better decision-making. This leads to more agile, responsive product development across departments.

In PLM, AI powers generative tools that create multiple design alternatives based on defined goals and constraints. These tools allow teams to explore, evaluate, and refine concepts earlier in the process. The result is reduced reliance on physical prototyping and faster time to market.

AI also strengthens risk management by identifying potential failures or supply chain issues before they escalate. By analyzing historical data alongside real-time inputs, AI can suggest preventative actions and optimize planning. This helps ensure greater resilience and operational continuity throughout the lifecycle.

Key Statistics and Trends Highlighting AI Adoption in PLM

Recent survey data shows that companies with PLM systems have 28% higher AI adoption in product development compared to their peers. Additionally, 59% of firms cite greater use of AI as a critical success factor in product development, alongside IT modernization (47%) and digitalization (45%). Top AI use cases in PLM include process optimization and design concept development, both at 40%, as well as market forecasting at 39%.

Beyond industry-specific adoption metrics, McKinsey estimates that AI could generate up to $4.4 trillion in productivity gains across enterprise systems, with PLM optimization playing a key role. This underscores AI’s transformative potential not only in engineering processes but across organizational productivity at scale.

On the operational front, AI-powered Bill of Materials (BOM) management tools have delivered striking efficiency improvements, reducing part classification errors by 78% and improving supplier-selection accuracy by 63%.

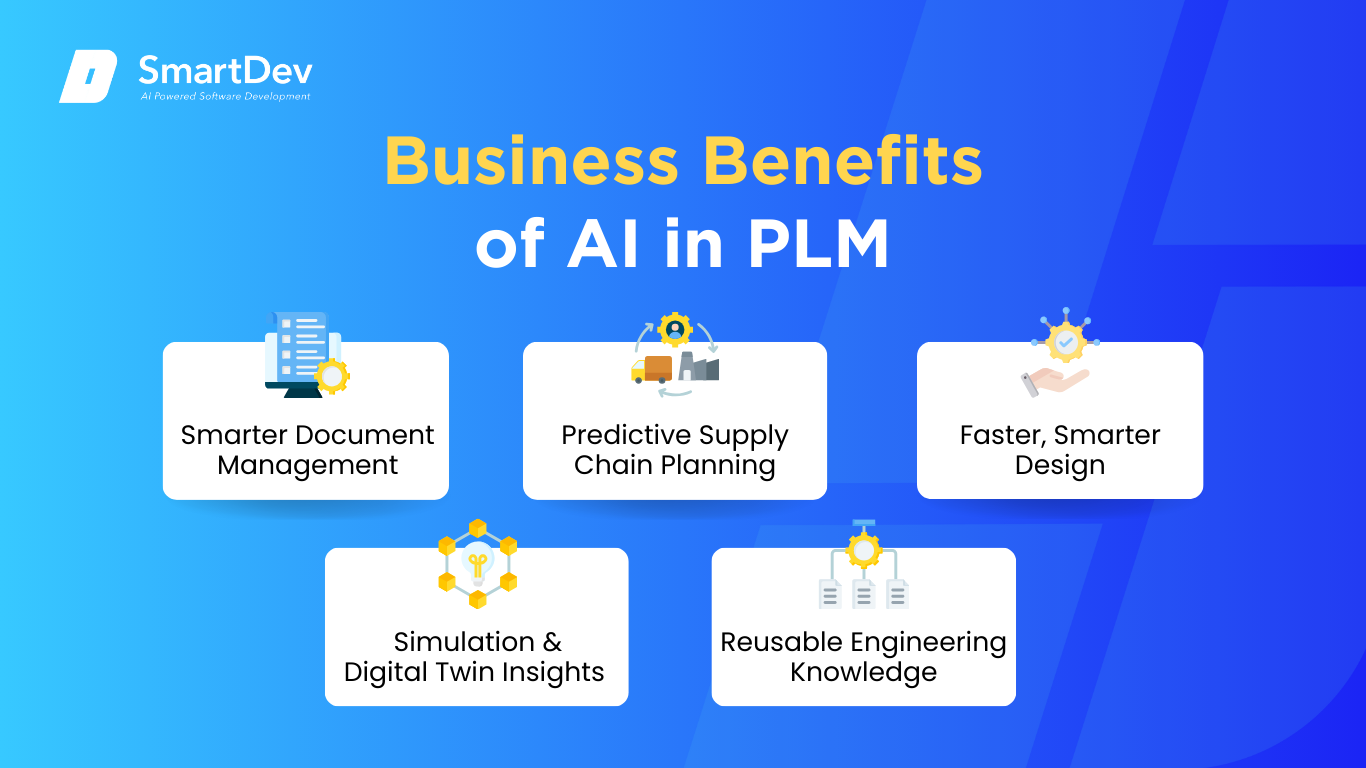

Business Benefits of AI in PLM

AI is driving measurable improvements across every phase of the product lifecycle. From faster design cycles to smarter risk management, it enables PLM teams to work more efficiently, make better decisions, and bring higher-quality products to market faster.

1. Smarter Document Management

AI improves how PLM systems handle unstructured documents like specifications and compliance records. Natural language processing extracts key information and makes it searchable across product versions. This reduces manual work and speeds up access to critical data.

Tools like retrieval-augmented generation (RAG) allow teams to query documents using everyday language. Engineers and compliance teams can quickly find what they need without digging through files. Faster access helps resolve issues and improve response times.

2. Predictive Supply Chain Planning

AI analyzes supplier data, historical trends, and external risks to forecast disruptions before they occur. This enables proactive planning and fewer delays in production. It supports more stable, resilient supply chains.

Generative tools also recommend alternative suppliers or materials in real time. These suggestions help teams adapt quickly during disruptions. As a result, businesses maintain continuity and reduce the impact of unforeseen events.

3. Faster, Smarter Design

AI generates optimized design options based on cost, performance, or sustainability goals. Teams can test ideas earlier and reduce the need for physical prototypes. This speeds up development and encourages innovation.

With generative design tools built into PLM, engineers catch flaws sooner and align outputs with product goals. Simulation helps validate choices before production begins. The result is fewer errors and faster time to market.

4. Simulation and Digital Twin Insights

AI supports predictive simulations that show how products perform under real-world conditions. This helps engineers detect risks early and refine designs before physical testing. It improves quality and reduces rework.

Digital twins create a live model of the product throughout its lifecycle. Real-time data feeds back into design and maintenance strategies. This continuous loop drives better performance and ongoing optimization.

5. Reusable Engineering Knowledge

AI-enabled PLM systems embed engineering logic and best practices into templates and rules. This allows teams to reuse validated components across projects. It reduces design time and ensures consistency.

Knowledge-Based Engineering also automates routine tasks and supports standard compliance. It preserves institutional knowledge and speeds up onboarding for new teams. The result is better scalability and fewer design mistakes.

Challenges Facing AI Adoption in PLM

Despite its promise, integrating AI into PLM comes with real barriers that organizations must address. These challenges range from technical constraints to organizational readiness, and they often determine whether AI delivers real value or remains underutilized.

1. Unstructured and Inconsistent Data

PLM systems often manage large volumes of unstructured data from CAD models, specifications, and historical documents. Without consistent formats and clean metadata, AI tools struggle to extract useful insights. Poor data quality leads to inaccurate outputs and limited automation value.

To make AI effective, organizations must invest in data cleansing, standardization, and governance. This includes aligning engineering, manufacturing, and IT teams around a shared data strategy. Without that foundation, AI adoption remains limited to narrow use cases.

To learn how unstructured data can be effectively leveraged in AI applications, check out our detailed guide on how AI unlocks the power of unstructured data.

2. Complex System Integration

PLM spans multiple tools – CAD, ERP, simulation, and more – each with its own data formats and workflows. Integrating AI across these systems requires custom connectors, strong APIs, and unified data models. Fragmentation slows adoption and adds technical debt.

Organizations need scalable platforms that support modular AI integration across disciplines. Without seamless interoperability, AI insights get trapped in silos. This prevents teams from realizing full lifecycle visibility and collaboration.

3. High Simulation and Validation Costs

AI-enabled simulations and predictive models need accurate data, advanced tools, and substantial computing power. Building these models requires time, resources, and expert oversight. For many companies, the upfront cost outweighs immediate benefits.

Balancing speed, accuracy, and cost is a constant challenge. Lightweight simulations may lack precision, while high-fidelity models slow down processes. Finding the right trade-off is critical to success.

4. Difficulty Scaling from Pilots to Enterprise

AI adoption often begins with small-scale pilots in isolated teams or departments. Scaling those solutions organization-wide involves process redesign, user training, and platform upgrades. Many initiatives stall due to lack of strategic alignment or IT readiness.

Enterprise-wide adoption also demands robust change management and clear governance. Without clear ownership and KPIs, AI projects risk becoming disconnected experiments. Scaling requires leadership support and a long-term roadmap.

5. Shortage of Cross-Functional Expertise

Effective AI in PLM requires collaboration between engineers, data scientists, and IT professionals. These skill sets are rarely found in a single team, making cross-functional alignment difficult. Miscommunication between roles can delay or derail projects.

Companies must invest in talent development and foster integrated teams that understand both domain expertise and AI capabilities. Building this bridge is essential for successful implementation. Without it, even well-designed AI tools may go unused.

Specific Applications of AI in PLM

1. Predictive Analytics for Risk and Failure Forecasting

AI-powered predictive analytics identifies risks and failures across the product lifecycle by analyzing historical and real-time data. These systems apply machine learning algorithms to detect deviations in sensor readings, maintenance logs, and usage trends, anticipating breakdowns before they occur. When integrated into PLM, this foresight reduces costly disruptions and improves product quality and reliability.

Predictive models use supervised learning techniques trained on labeled failure data, feeding into dashboards or alerts within PLM workflows. These alerts guide proactive maintenance, redesign decisions, or supplier adjustments based on predicted risks. The value lies in minimizing downtime, reducing warranty claims, and streamlining design iterations.

Operationally, this helps manufacturers shift from reactive maintenance to condition-based or predictive strategies. However, building such systems requires well-labeled data, real-time connectivity, and vigilance against model bias and false positives. Human validation ensures that predictions are contextually relevant and actionable.

Real-World Example

Tesla uses AI-based predictive analytics to optimize its vehicle and manufacturing maintenance schedules, using sensor data to forecast failures. This approach has reduced downtime and reactive repair costs while improving production efficiency by over 30%.

2. Generative Design and BOM Optimization

Generative design uses AI algorithms like topology optimization and genetic algorithms to automatically generate product designs based on user-defined constraints. This replaces manual CAD iterations with AI-generated design alternatives optimized for cost, performance, weight, or material. When tied to BOM data in PLM, the system can recommend not just what to design, but how to source it effectively.

Design teams input parameters like load capacity, dimensions, and material preferences. The AI evaluates thousands of potential designs and refines them against real-world constraints, producing models that integrate directly into PLM workflows. This drastically accelerates development time and ensures designs are production-ready and cost-effective.

Benefits include faster prototyping, reduced material waste, and superior structural performance. However, implementation demands advanced simulation tools, accurate material data, and compliance validation to avoid manufacturing mismatches. Generative design also requires cultural shifts in engineering workflows to embrace AI suggestions.

Real-World Example

NASA’s Evolved Structures project applied AI-based generative design to spacecraft components, achieving 10x faster development and 3x stronger structural outcomes. The project used Autodesk Fusion 360 and Siemens NX to simulate and evaluate configurations before production.

3. Natural Language Interaction and Search in PLM

Natural Language Processing (NLP) enables engineers and non-technical users to query PLM systems using conversational language instead of complex filters. AI models interpret user intent and retrieve relevant design files, compliance records, or supplier details instantly. This simplifies system navigation and improves data accessibility across departments.

PLM platforms equipped with LLMs understand queries like “Show the most recent version of Product X” or “List all parts that failed inspection last quarter.” These models connect to structured data tables, documents, and metadata to deliver contextually accurate answers. This removes the need for advanced system training and speeds up collaboration.

By making PLM data more accessible, companies reduce bottlenecks and improve operational agility. However, such systems must be carefully trained with domain-specific vocabulary and governed for data access control. Explainability and trust in AI-generated answers remain critical for enterprise adoption.

Real-World Example

Aras Innovator and other next-gen PLM platforms now include AI-driven natural language search, enabling users to ask questions like “What components are non-compliant with RoHS?” These queries return structured results across documents, version control, and BOMs in seconds.

4. Digital Twins and Simulation for Lifecycle Insights

Digital twins are real-time virtual models of physical products that mirror behavior across the lifecycle using sensor feedback and operational data. AI enhances digital twins by simulating how changes in design, usage, or environment will impact performance over time. These insights feed directly into PLM systems to refine future product versions.

Simulation data from twins enables iterative design without physical prototypes, reducing development costs and speeding up innovation. Machine learning continuously adjusts the twin based on new inputs, creating a feedback loop that links design, manufacturing, and service. This closed-loop improves product quality, reliability, and lifecycle cost forecasting.

Digital twins also aid predictive maintenance, product personalization, and sustainability planning. Challenges include high integration costs, data standardization, and real-time synchronization across systems. Security and IP protection are also essential when modeling sensitive products.

Real-World Example

Rolls-Royce uses digital twins to monitor aircraft engine health, feeding data into PLM for ongoing design optimization. This AI-enhanced twin system enables predictive service planning, reducing unscheduled maintenance by 30% and improving engine uptime.

5. Automated Document Processing and Data Extraction

AI automates the ingestion of engineering documents, like specs, supplier sheets, or compliance records, by extracting structured data using NLP and computer vision. These tools convert PDFs, scans, and text into usable PLM entries, reducing manual data entry and associated errors. This speeds up onboarding and supports faster project initiation.

Optical Character Recognition (OCR) combined with natural language models reads technical documents, identifies key fields (e.g., material type, certification date), and maps them into predefined PLM schemas. Integrations with email systems or supplier portals further streamline input flows. Companies benefit from fewer data gaps, increased documentation consistency, and improved auditability.

Challenges include variable document quality, inconsistent templates, and domain-specific terminology. Models must be fine-tuned to each use case and validated against regulatory requirements. Human QA may still be required for critical entries.

Real-World Example

Trace One implemented AI-based document processing to ingest and categorize supplier specifications across its PLM platform. They achieved faster onboarding, reduced manual input by 60%, and improved regulatory document completeness by over 30%.

6. Knowledge Graph–Based Traceability and Reuse

Knowledge graphs map relationships among requirements, components, tests, and processes, creating a web of traceable links within PLM systems. AI uses these graphs to surface insights, such as component lineage, dependency chains, or regulatory impact, based on real-time context. This promotes transparency, reuse, and design integrity across complex systems.

Unlike traditional linear databases, graph-based PLM allows engineers to explore cause-and-effect across multiple dimensions of a product. Changes in one part automatically propagate through the graph, alerting teams to risks or required updates. AI-driven validation ensures that reused parts meet current specifications and compliance.

Traceability via knowledge graphs accelerates audits, ensures version alignment, and reduces rework. However, creating and maintaining the graph layer requires deep domain modeling and robust metadata tagging. Graph security and scalability are key considerations in enterprise deployments.

Real-World Example

Siemens applies graph-based PLM in its smart manufacturing operations to dynamically trace component connections and manufacturing capabilities. This graph-driven approach improves configuration accuracy and enables AI explainability in engineering decisions.

Need Expert Help Turning Ideas Into Scalable Products?

Partner with SmartDev to accelerate your software development journey — from MVPs to enterprise systems.

Book a free consultation with our tech experts today.

Let’s Build TogetherExamples of AI in PLM

Real-world applications of AI in PLM highlight how leading companies are transforming their product development and lifecycle strategies. The following case studies demonstrate measurable business outcomes driven by AI adoption across aerospace, manufacturing, and engineering sectors.

Real-World Case Studies

1. Rolls-Royce: Digital Twins for Predictive Maintenance

Rolls-Royce pioneered the use of AI-enhanced digital twins to monitor the lifecycle performance of its aircraft engines. By continuously feeding operational sensor data into AI models, Rolls-Royce predicts maintenance needs before failures occur, reducing costly downtime. This system also helps engineers refine future designs based on real-world usage patterns.

As a result, Rolls-Royce reduced unscheduled maintenance by 30%, increased engine uptime, and improved customer satisfaction. The company partnered with IFS and Microsoft to scale its AI and PLM infrastructure across global operations.

2. Airbus: Generative Design for Lightweight Aircraft Structures

Airbus collaborated with Autodesk to redesign the A320’s cabin partition using generative design and AI modeling. Inspired by biological structures, the AI created a “bionic partition” that is 45% lighter and equally strong compared to traditional designs. The component was 3D-printed using Scalmalloy, a high-performance aerospace material.

The weight savings contribute to fuel efficiency and reduce emissions – projected to save up to 465,000 metric tons of CO₂ annually if applied across the fleet. This project showcases how AI-driven design integrated with PLM can meet strict aerospace regulations while improving sustainability.

3. Eaton: Accelerated Product Development with Generative AI

Eaton, a global power management company, implemented AI-based generative design with aPriori to improve the early stages of product development. By automatically generating and evaluating multiple design variants based on manufacturability and cost constraints, the team drastically shortened design cycles. The system also integrated with PLM platforms to track revisions and compliance.

This AI implementation led to an 87% reduction in development time, with higher design quality and faster transition to manufacturing. It highlights how companies can embed AI early in the product lifecycle to drive efficiency, scalability, and innovation.

Innovative AI Solutions

AI is redefining PLM by enabling predictive design, automated compliance checks, and intelligent design assistance. It acts as a co-pilot for engineers, proposing solutions and automating repetitive tasks across workflows. As product cycles accelerate, AI ensures faster, more accurate, and sustainable innovation.

The convergence of digital twins and generative AI is creating adaptive, simulation-driven design environments. These AI-powered twins model real-world behavior and generate optimized design alternatives within PLM systems. This reduces prototyping costs, enhances accuracy, and creates a self-improving development loop.

Explore how AI streamlines workflows and drives performance improvements in our guide to unlocking operational efficiency with AI.

AI-Driven Innovations Transforming PLM

Emerging Technologies in AI for PLM

AI is transforming product lifecycle management through predictive analytics, multimodal data integration, and digital twin technologies. These innovations allow PLM systems to forecast design issues, unify data from documents, images, and models, and simulate product behavior across its lifecycle. The result is faster iteration, better cross-functional collaboration, and reduced reliance on costly physical prototypes.

Advancements like predictive engineering analytics and virtual product development push PLM further into proactive, simulation-led design. Predictive analytics enables teams to test systems earlier, reducing errors and improving quality from the start. Digital environments also let engineers explore form and function virtually, streamlining decisions before physical production begins.

AI’s Role in Sustainability Efforts

AI enhances sustainability in PLM by streamlining life-cycle assessments and optimizing material, energy, and waste decisions. It enables real-time tracking of emissions and environmental impacts across the product journey, allowing companies to target high-impact areas with precision. This visibility supports better design decisions and aligns PLM strategies with circular economy goals.

Digital prototyping powered by AI reduces the need for physical samples, cutting both material waste and emissions from transportation. Predictive analytics also helps teams refine products early, ensuring sustainable performance before production begins. These capabilities drive greener operations while maintaining cost-efficiency and regulatory compliance.

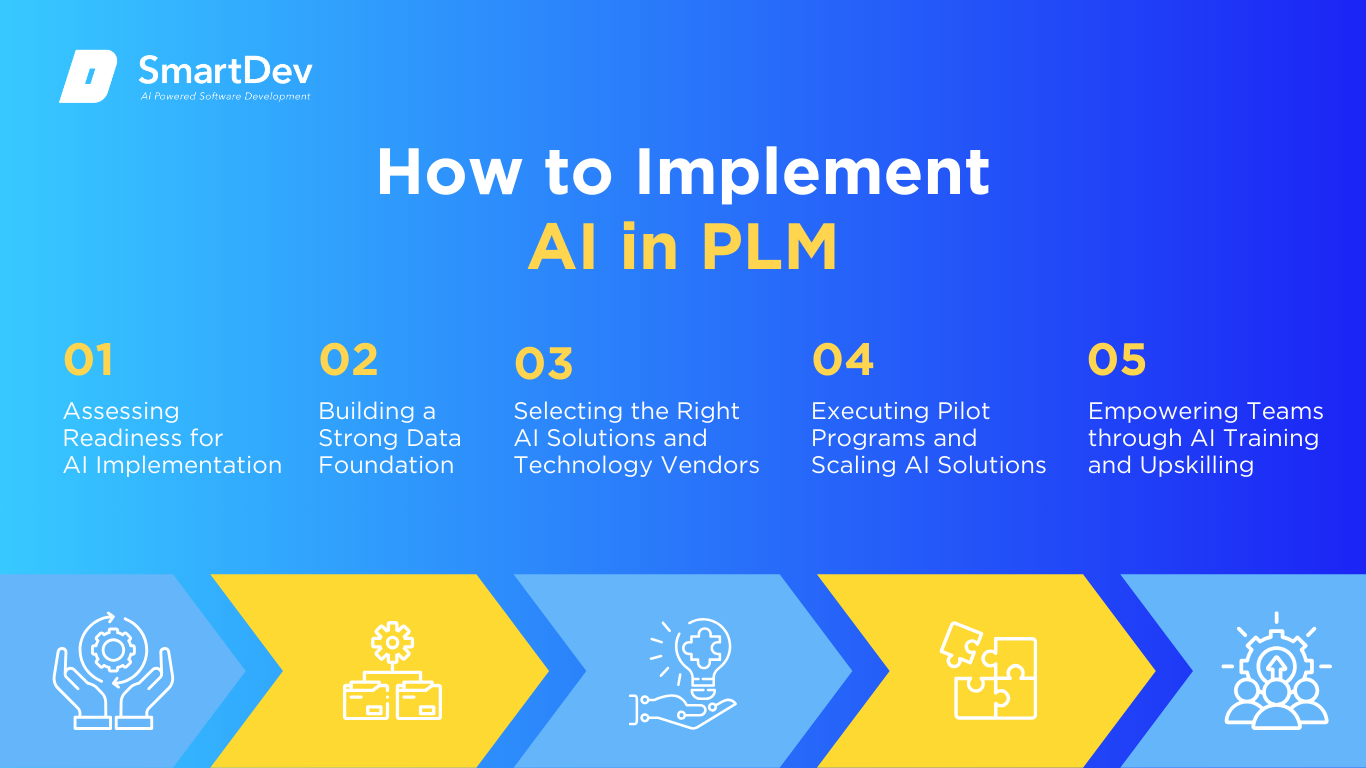

How to Implement AI in PLM

Implementing AI in PLM isn’t just a technology upgrade, it’s a strategic transformation that touches data, processes, and people. To do it right, you need a phased approach that ensures alignment, minimizes disruption, and builds long-term value.

Step 1: Assessing Readiness for AI Adoption

Before introducing AI into your PLM strategy, take time to evaluate your organization’s digital maturity. Focus on areas where teams are burdened by manual tasks like data entry, compliance tracking, or BOM updates. These functions are often ideal for AI because they’re repetitive, measurable, and less likely to disrupt core workflows.

You’ll also need to gauge leadership support and how receptive teams are to change. AI adoption often shifts how engineering and operations collaborate, which can challenge long-standing habits. Without alignment from key stakeholders, even well-designed pilots can stall or fail to scale.

Explore our data analytics services to see how we help businesses implement AI solutions that scale.

Step 2: Building a Strong Data Foundation

AI in PLM depends on a steady stream of high-quality, well-structured data. That includes everything from product specs and CAD files to supplier documentation and change logs. Consistent, accessible data is what allows AI models to generate reliable predictions and insights.

Establishing centralized data systems is key to unifying siloed teams and ensuring traceability. Invest in data governance practices to manage accuracy, version control, and compliance across the product lifecycle. The stronger your data foundation, the more scalable and effective your AI initiatives will be.

Explore why clean, well-governed data is the foundation of successful AI adoption in our data management guide.

Step 3: Choosing the Right Tools and Vendors

The right AI tools for PLM go beyond features, they must align with your engineering and product goals. Look for vendors who understand complex development cycles and can provide solutions tailored to your industry. The best tools fit into existing PLM workflows without requiring costly system overhauls.

Make sure integration is seamless and supports long-term scalability. It’s also important to review how vendors handle your IP and engineering data, especially when third-party AI models are involved. A transparent, security-conscious partner can make or break your AI deployment success.

Step 4: Pilot Testing and Scaling Up

Start small by piloting AI in a low-risk part of your product lifecycle, like automating document validation or speeding up design reviews. These early experiments help your teams understand how AI behaves in real-world conditions and reveal friction points in your workflows. A successful pilot builds credibility and clears the path for broader implementation.

Use pilot outcomes to refine both the technology and your internal processes. Measure the impact on productivity, speed, and quality, then iterate before scaling. Once value is proven, you can expand with greater confidence and less resistance.

Step 5: Training Teams for Successful Implementation

AI tools are only as effective as the teams using them. Invest in upskilling engineers, product managers, and support teams on how AI enhances – not replaces – their expertise. Emphasize how AI can handle the heavy lifting while people focus on innovation and oversight.

Foster collaboration between technical and operational roles to integrate AI smoothly into daily routines. When users trust the tools and understand their function, adoption becomes more natural. A well-trained team ensures consistent, high-value use of AI across your PLM environment.

To ensure successful AI integration, institutions should start with a clear roadmap. Our guide for tech leads outlines how to assess readiness and align stakeholders from the start.

Measuring the ROI of AI in PLM

Key Metrics to Track Success

Tracking ROI begins with clear operational metrics – like reduction in engineering change orders, faster design approvals, and shortened product development cycles. These improvements signal that AI is streamlining processes and removing friction from cross-functional collaboration. They’re often the first indicators of value before hard financial gains appear.

Over time, you can measure more direct returns through cost reductions in prototyping, fewer compliance penalties, and increased design reuse. AI also improves early error detection, lowering the cost of late-stage corrections and improving product quality. These gains contribute to higher margin and better product performance across the lifecycle.

Case Studies Demonstrating ROI

Breg, a medical device company, reported a 186% ROI and full payback in just over a year after adopting Propel’s AI-enabled PLM and QMS platform. Engineering time dropped by 77%, and quality document control was cut in half through centralized data and automation.

A Forrester study of Siemens’ Teamcenter X found that cloud-based PLM with AI capabilities helped reduce IT overhead while accelerating product development. These tools improved process consistency and supported faster innovation cycles, leading to measurable business value.

Common Pitfalls and How to Avoid Them

Many companies fail to realize AI’s full ROI because they focus too heavily on short-term gains or lack a strong data foundation. When data is fragmented or incomplete, AI tools produce inconsistent results that erode user trust. Building a clean, centralized data system should be a foundational step before measuring returns.

Another common misstep is treating AI use cases in isolation. Piloting a single AI tool without considering its role across the full product lifecycle can limit its impact. The most successful companies scale AI across multiple PLM touchpoints to unlock cumulative, long-term value.

Learn how to evaluate AI model effectiveness and ROI with our practical guide on AI performance metrics.

Future Trends of AI in PLM

Predictions for the Next Decade

AI-enhanced digital twins are poised to revolutionize PLM by creating continuously updated, high-fidelity virtual models that incorporate real-time operational data for predictive insights and performance optimization. These models will reduce prototyping costs and accelerate decision-making across the product lifecycle.

Moreover, the rise of agentic and multimodal AI capabilities will transform PLM software into proactive collaborators capable of analyzing text, images, CAD files, and field data to autonomously suggest optimizations or enhancements. This shift will make AI a core driver of innovation, moving PLM from data storage to active design collaboration.

To see which emerging technologies are shaping AI adoption in the next decade, our IT landscape trends recap and guide for business to intergrating AI in 2025 breaks down the must-watch shifts for business leaders.

How Businesses Can Stay Ahead of the Curve

To stay competitive, companies must prioritize building AI-ready infrastructure – starting with clean, centralized PLM data and scalable cloud platforms. Businesses that invest early in data governance and model transparency will be better positioned to adopt AI responsibly and efficiently as the technology matures.

Equally important is fostering a culture that embraces AI as a partner in innovation, not just a productivity tool. Upskilling teams, encouraging experimentation, and aligning AI initiatives with business strategy will help organizations adapt quickly and lead in a rapidly evolving product development landscape.

Conclusion

Key Takeaways

AI is redefining product lifecycle management by streamlining repetitive processes, enhancing decision-making, and accelerating time-to-market. From predictive analytics and digital twins to sustainability optimization and smart automation, AI is reshaping how products are designed, built, and managed. These innovations are already delivering measurable ROI through cost savings, improved quality, and operational efficiency.

Successful adoption hinges on clean data, thoughtful implementation, and strong team alignment. Companies that start with targeted use cases and scale AI strategically are seeing the biggest gains. As AI technologies evolve, PLM will continue shifting from a static system of record to a dynamic engine of innovation.

Moving Forward: A Strategic Approach to AI-Driven Transformation

As AI continues to reshape product development, now is the time to rethink how your organization manages the full lifecycle – from design to delivery. With benefits like faster iterations, reduced rework, and smarter decision-making, AI is no longer a futuristic concept, it’s a strategic advantage in today’s competitive market.

At SmartDev, we help businesses integrate AI into their PLM systems to streamline operations and accelerate innovation. Whether you’re automating compliance checks, optimizing BOMs, or enabling predictive design, our team builds tailored solutions that deliver measurable ROI and long-term value.

Explore our AI-powered software development services to see how we create custom PLM solutions for product data integration, predictive lifecycle analytics, and real-time engineering insights.

Contact us today to learn how AI can power your next-generation PLM transformation and keep you ahead of the curve.

—

References:

- The PLM Advantage: Global Survey Reveals Edge in AI Adoption, Compliance, and More | aras.com

- AI in PLM: Transforming Product Lifecycle Management for the Digital Age | RFID Journal

- Leveraging AI for Enhanced Product Life Cycle Management (PLM) Transformation | ResearchGate

- Planning and Product Lifecycle Management (PLM) solution | EY

- How Tesla and BMW Use AI-Driven Predictive Maintenance to Reduce Downtime | Cleverance software

- Generative Design and Digital Manufacturing: Using AI and robots to build lightweight instruments | NASA (.gov)

- Cognitive Product Design: Empowering Non-Technical Users Through Natural Language Interaction With AI-Native PLM | AiThority

- Digital twins: The art of the possible in product development and beyond | McKinsey & Company

- Autodesk and Airbus Demonstrate the Impact of Generative Design on Making and Building | Autodesk News

- Revolutionizing Manufacturing with AI: Real-World Case Studies Across the Industry | getstellar.ai

- Discover the ROI of cloud-based PLM | Siemens Blog Network

- State-of-the-Art Review: The Use of Digital Twins to Support Artificial Intelligence-Guided Predictive Maintenance | arXiv