Introduction

Distribution networks today face increasing pressure to operate faster, smarter, and leaner. Supply chain disruptions, labor shortages, shifting demand patterns, and rising customer expectations are testing the limits of traditional systems. Artificial Intelligence (AI) is emerging as a strategic lever, helping distributors overcome inefficiencies, enhance agility, and drive bottom-line results.

This guide unpacks how AI is reshaping the distribution sector from intelligent inventory management to last-mile optimization while highlighting tangible benefits and adoption challenges.

What is AI and Why Does It Matter in Distribution?

Definition of AI and Its Core Technologies

Definition of AI and Its Core Technologies

Artificial Intelligence (AI) refers to computer systems capable of performing tasks that typically require human intelligence, such as learning from data, recognizing patterns, and making decisions. It draws on technologies such as machine learning, natural language processing (NLP), and computer vision to analyze large datasets and derive actionable insights (IBM).

In the context of distribution, AI enables systems to dynamically optimize warehouse operations, forecast inventory needs with greater accuracy, and predict supply chain risks before they disrupt fulfillment. These tools are transforming the way distribution centers operate, not just by automating routine tasks but by turning logistics into a competitive advantage.

Want to explore how AI can transform your sector? Discover real-world strategies for deploying smart technologies in airline systems. Visit How to Integrate AI into Your Business in 2025 to get started today and unlock the full potential of AI for your business!

The Growing Role of AI in Transforming Distribution

Distribution has traditionally relied on static forecasts, manual scheduling, and human-driven decision-making. Today, AI systems bring real-time adaptability to those processes. Machine learning models ingest sales history, market signals, and supplier data to generate demand forecasts that evolve continuously. This reduces inventory waste and prevents stockouts.

Warehouse automation, powered by AI, streamlines picking and packing by optimizing the movement of goods based on item popularity and order timing. AI also assists in labor allocation by analyzing past performance and seasonal spikes, ensuring optimal staffing without overcommitting.

Beyond the warehouse, AI transforms transportation and delivery. Route optimization algorithms analyze traffic, weather, and delivery windows to cut fuel costs and improve customer experience. In an industry where timing is everything, AI delivers precision.

Key Statistics or Trends in AI Adoption

AI adoption is accelerating in distribution and supply chain. According to a 2023 McKinsey survey, 40% of supply chain leaders are actively scaling AI-driven demand planning solutions, with projected cost reductions of up to 15% and service level improvements by 35% (McKinsey).

A Deloitte study revealed that 45% of distribution and logistics firms have implemented AI to support warehouse automation or predictive maintenance—highlighting a clear shift from experimentation to operational integration (Deloitte).

The market for AI in logistics and distribution is expected to grow at a CAGR of 23.5%, reaching $12 billion by 2030, according to Allied Market Research. These trends underscore the urgency for decision-makers to adopt AI or risk falling behind.

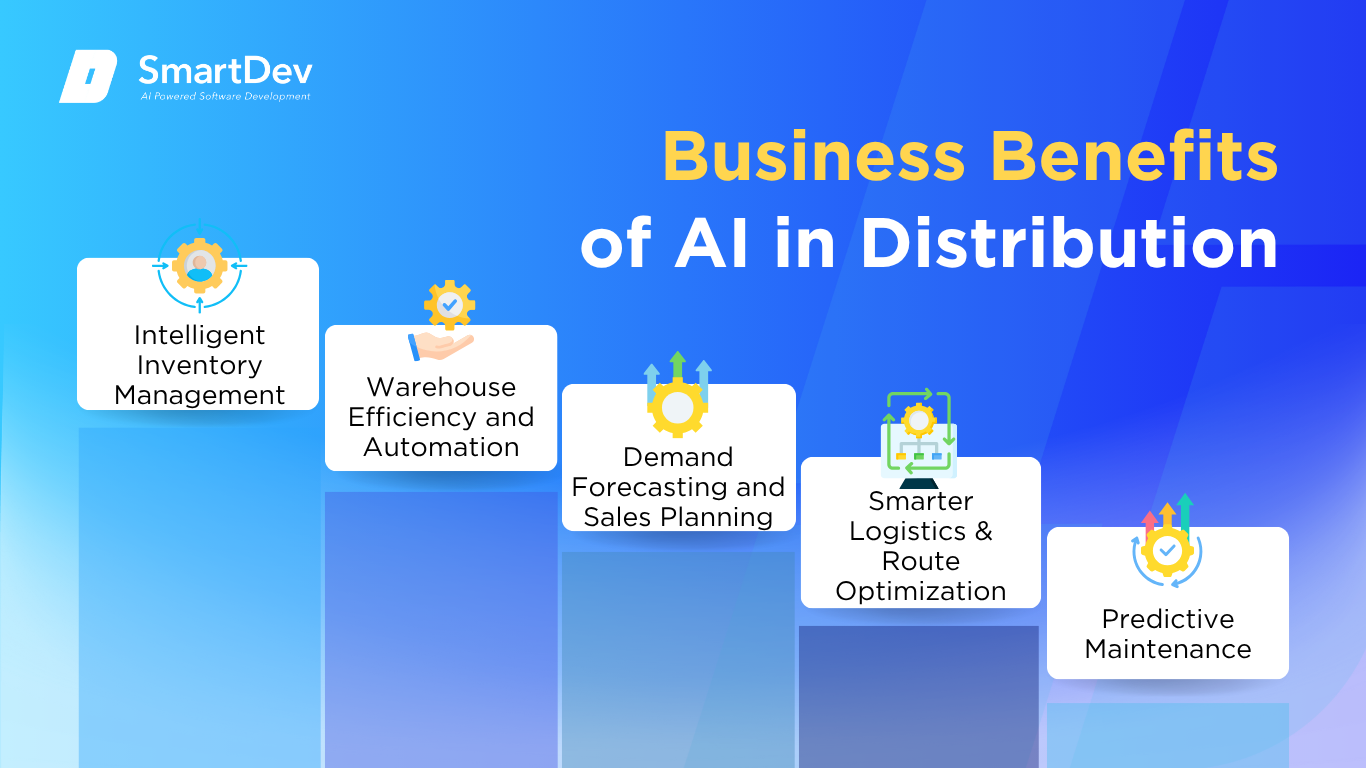

Business Benefits of AI in Distribution

AI in distribution isn’t just about future potential—it’s solving pressing operational challenges today. Below are five key benefits that highlight its real-world value.

1. Intelligent Inventory Management

1. Intelligent Inventory Management

Inventory mismanagement leads to either excess stock or costly shortages. AI solves this by analyzing sales velocity, seasonality, and supplier lead times to create more accurate, dynamic forecasts. This reduces both overstocking and understocking risks.

For example, AI-driven inventory platforms adjust reorder points in real-time based on changes in demand patterns, market disruptions, or promotional campaigns. Distributors using such systems report inventory cost reductions of up to 30%.

2. Warehouse Efficiency and Automation

Manual warehouse operations are time-consuming and error-prone. AI enhances warehouse execution by optimizing the placement of goods and directing autonomous mobile robots (AMRs) for picking tasks.

Advanced vision systems powered by AI also improve quality control by detecting damaged items or incorrect packaging. This increases throughput and reduces costly returns or reshipments.

3. Demand Forecasting and Sales Planning

Traditional forecasting relies on historical averages. AI models, on the other hand, consider hundreds of variables—like customer behavior, macroeconomic shifts, and even weather—to produce more accurate predictions.

This has a direct impact on cash flow and customer satisfaction. Distributors can align procurement, production, and promotions more effectively, reducing waste and improving on-time fulfillment.

4. Smarter Logistics and Route Optimization

Fuel costs and delivery delays are major pain points. AI-driven logistics systems analyze traffic conditions, delivery time windows, and real-time constraints to optimize delivery routes.

This not only lowers transportation costs but also increases the predictability of deliveries. Companies like DHL and UPS have reduced miles driven by over 10% through AI-powered route planning systems (UPS).

5. Predictive Maintenance and Asset Health Monitoring

Equipment downtime can cripple distribution operations. AI enables predictive maintenance by analyzing machine data to detect anomalies before they lead to failures.

This reduces unplanned downtime and extends equipment lifespan. For example, AI solutions that monitor conveyor belts and forklifts have helped facilities reduce maintenance costs by 20% while improving safety and uptime.

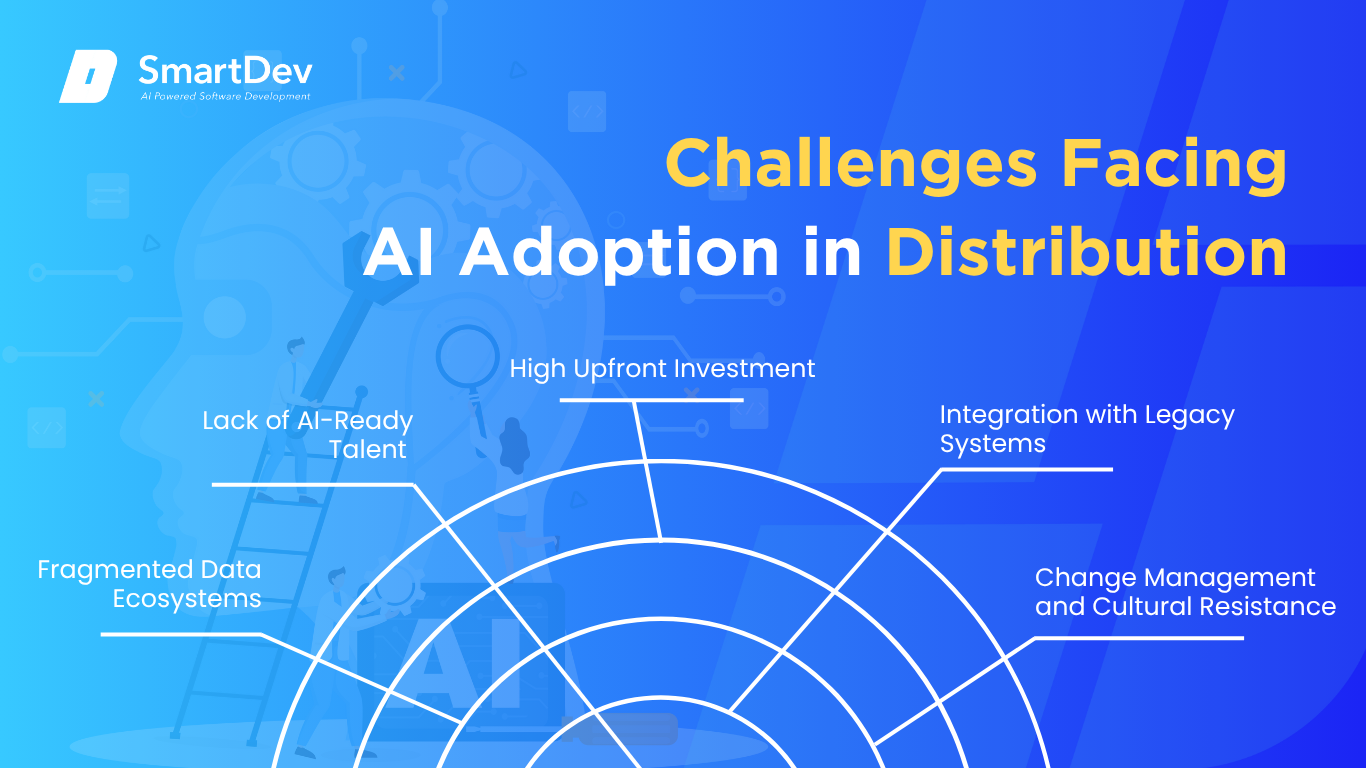

Challenges Facing AI Adoption in Distribution

Despite the benefits, adopting AI in distribution isn’t without challenges. These obstacles often stem from data issues, organizational resistance, and system complexity. Here’s a closer look at five key barriers.

1. Fragmented Data Ecosystems

1. Fragmented Data Ecosystems

Distribution data is often spread across ERP systems, WMS platforms, supplier emails, and legacy spreadsheets. Without centralized, structured data, AI tools cannot function effectively.

To overcome this, companies must invest in data integration frameworks and ensure consistent governance across departments—a resource-heavy but essential step for AI readiness.

Building responsible AI starts with awareness. Learn how to tackle real-world bias in our guide on AI fairness and ethical strategies.

2. Lack of AI-Ready Talent

Even when tools are available, a shortage of data scientists and AI engineers can slow implementation. Many distribution companies struggle to recruit or upskill staff who can translate operational needs into AI use cases.

Partnerships with AI solution providers or third-party integrators can help bridge this gap temporarily, but long-term strategies must include internal capability building.

3. High Upfront Investment

AI projects often require significant upfront costs in software, sensors, cloud infrastructure, and training. For cost-sensitive operations, this can be a deterrent.

To mitigate risk, companies can start with pilot projects in high-impact areas like inventory or demand planning—demonstrating quick wins to justify broader investments.

4. Integration with Legacy Systems

Many distributors rely on aging WMS, TMS, or ERP platforms that aren’t designed for AI integration. This creates friction when trying to embed intelligent features into daily workflows.

API-driven middleware or modular AI layers can enable gradual integration without full system overhauls. Still, this requires strategic planning and alignment between IT and operations.

For those navigating these complex waters, a business-oriented guide to responsible AI and ethics offers practical insights on deploying AI responsibly and transparently, especially when public trust is at stake.

5. Change Management and Cultural Resistance

Employees accustomed to manual processes may see AI as a threat rather than a tool. Without clear communication and involvement in the rollout, even the best technology can face adoption pushback.

Successful change management includes training, transparency, and highlighting how AI enhances—not replaces—human work. Leaders must frame AI as a co-pilot, not a competitor.

Specific Applications of AI in Distribution

AI is revolutionizing the distribution sector by automating core functions, enhancing accuracy, and enabling real-time decision-making. In this section, we explore six high-impact AI applications transforming modern distribution, from warehouses to last-mile delivery.

1. Demand Forecasting and Inventory Optimization

1. Demand Forecasting and Inventory Optimization

Demand forecasting is one of the most critical components in distribution. Overestimating demand results in excess inventory and wasted storage, while underestimating leads to lost sales and supply chain disruptions. AI-driven forecasting models solve this by identifying complex, non-linear patterns in historical sales, weather, promotional campaigns, and economic signals.

These models use machine learning algorithms such as Random Forests and Recurrent Neural Networks (RNNs) to process structured and unstructured data from multiple sources. AI integrates with ERP and WMS systems to adjust inventory levels in real-time based on anticipated changes in demand. This improves planning accuracy and reduces costly overstocking or understocking.

The strategic value is clear: better demand forecasts translate into more efficient procurement, storage, and fulfillment. It also improves supplier coordination and customer satisfaction. While accuracy improves with more data, early-stage adoption requires sufficient data governance and quality controls.

Real-World Example: Walmart leverages AI and machine learning to forecast demand across its global network of distribution centers. Using proprietary tools that combine internal sales data with external market signals, Walmart has reduced inventory carrying costs by 10% and improved in-stock rates, enhancing both profitability and customer experience.

2. Warehouse Automation and Robotics Optimization

Distribution centers face intense pressure to fulfill more orders faster and with greater accuracy. AI-powered warehouse automation addresses these challenges by directing robotic systems to optimize picking, sorting, and movement of goods. These systems enhance productivity while reducing human error.

At the core of warehouse AI is computer vision and reinforcement learning. AI enables real-time spatial mapping, determines optimal product placement, and continuously refines robot pathing to minimize travel distance. Integrations with WMS and IoT sensors ensure synchronized operations across robotic and human workflows.

Operational value includes faster throughput, reduced picking errors, and lower labor costs. However, integrating robotics into legacy systems can be costly and requires robust IT support. Ethical concerns also arise around workforce displacement and retraining.

Real-World Example: Ocado, a UK-based online grocer, uses AI-powered robotics to automate picking in its distribution centers. Its proprietary “Hive” system coordinates thousands of robots using real-time AI optimization. As a result, Ocado achieved a 99.9% order accuracy rate and increased throughput by 50%, becoming one of the most efficient grocery distributors globally.

3. Route Optimization and Last-Mile Logistics

Last-mile delivery is often the most expensive and unpredictable part of the distribution chain. AI addresses this through intelligent route optimization—analyzing real-time traffic, weather, package size, and customer preferences to reduce delays and fuel consumption.

The technology relies on predictive algorithms, geospatial analytics, and dynamic scheduling. By integrating with TMS (Transportation Management Systems), AI platforms adjust delivery plans in real-time based on current conditions, ensuring packages reach destinations faster and with minimal disruption.

This not only reduces logistics costs but also enhances customer satisfaction through accurate ETAs and proactive communication. Data privacy and geolocation accuracy are critical considerations, especially in densely populated urban areas.

Real-World Example: FedEx uses AI through its Dynamic Route Optimization (DRO) platform, which integrates driver data, traffic patterns, and delivery timelines. The result: improved route efficiency by 12%, reduced fuel costs, and enhanced on-time delivery rates, helping FedEx stay competitive in the e-commerce era.

4. Predictive Maintenance of Distribution Equipment

Unexpected equipment failures can stall operations in high-volume distribution centers. AI-powered predictive maintenance uses sensor data to forecast mechanical issues before they occur, preventing costly downtime and repairs.

These systems analyze telemetry data from conveyor belts, forklifts, and HVAC units using machine learning models trained to recognize signs of wear, abnormal vibration, or overheating. Alerts are sent to maintenance teams well before a breakdown happens, enabling proactive servicing.

Strategically, this reduces unplanned downtime and extends the lifespan of critical assets. It also improves workplace safety. The main implementation challenge lies in installing and integrating IoT sensors into older, analog equipment.

Real-World Example: DHL uses AI-driven predictive maintenance across its global logistics hubs. By integrating IoT sensors with analytics tools, DHL has reduced downtime by 15% and maintenance costs by 20%, boosting operational continuity and employee safety.

5. Fraud Detection and Supply Chain Risk Monitoring

The complexity of global supply chains makes them vulnerable to fraud, theft, and compliance breaches. AI enhances security by detecting anomalies in financial transactions, shipment data, and supplier records.

AI models trained on historical fraud patterns identify suspicious behaviors, such as invoice manipulation or unusual routing. Natural language processing (NLP) tools also scan contracts and communications to flag compliance risks. These systems integrate with enterprise security platforms and supplier management software.

AI enables faster, more accurate risk assessments and reduces financial and reputational exposure. However, data integrity and bias in anomaly detection must be carefully managed to avoid false positives or discrimination.

Real-World Example: Maersk, the global shipping giant, uses AI to detect procurement fraud and manage risk across its distribution operations. Its AI tools flag duplicate invoices and supplier anomalies, saving the company an estimated $7 million annually in potential fraud losses.

6. Intelligent Customer Service and Order Tracking

In today’s “on-demand” world, customers expect real-time visibility into their orders. AI-powered chatbots and tracking systems enhance customer experience by delivering instant updates, answering queries, and providing proactive notifications.

These solutions leverage NLP, AI assistants, and backend integrations with inventory and logistics systems. AI bots learn from historical interactions to improve future responses and resolve issues without human intervention.

Operational benefits include reduced call volumes, faster resolution times, and improved customer loyalty. Ethical concerns around transparency and chatbot bias must be addressed through human oversight and regular auditing.

Real-World Example: Amazon uses AI-driven chatbots and real-time order tracking to handle millions of support requests monthly. Its virtual assistant, Alexa, can now provide order status updates and delivery ETA. This automation contributes to Amazon’s industry-leading customer satisfaction and reduced support costs.

Need Expert Help Turning Ideas Into Scalable Products?

Partner with SmartDev to accelerate your software development journey — from MVPs to enterprise systems.

Book a free consultation with our tech experts today.

Let’s Build TogetherExamples of AI in Distribution

Real-world examples highlight how AI is driving measurable improvements in distribution. These case studies provide insight into successful strategies, outcomes, and lessons learned.

Real-World Case Studies

1. Amazon: Robotics for Hyper-Efficient Fulfillment

1. Amazon: Robotics for Hyper-Efficient Fulfillment

Amazon’s use of AI-powered robotics in its fulfillment centers has transformed distribution at scale. Over 750,000 robots powered by computer vision and optimization algorithms handle item retrieval and order prep. Human workers are guided by AI to ensure precise packing and dispatch.

This system has improved efficiency by 25% and reduced fulfillment time from hours to minutes. Amazon now ships millions of packages daily with minimal errors, illustrating the scalability of AI in large distribution networks.

2. PepsiCo: AI-Powered Demand Forecasting

PepsiCo adopted AI to forecast demand across multiple SKUs and global distribution channels. Machine learning models analyze POS data, weather, and historical trends to inform production and inventory planning. AI also adjusts forecasts in real-time based on promotions or market shifts.

As a result, PepsiCo reduced out-of-stock incidents by 30% and cut inventory carrying costs. Their AI solution enabled faster, data-backed decision-making across its supply chain.

3. XPO Logistics: Dynamic Delivery Optimization

XPO Logistics implemented AI-powered route optimization across its last-mile delivery network. By analyzing live traffic, driver schedules, and package dimensions, the system adjusts routes on the fly for maximum efficiency. AI also helps pre-empt delivery delays.

This led to a 20% improvement in delivery accuracy and a 15% reduction in fuel consumption. XPO’s customer satisfaction scores also improved due to accurate delivery ETAs and proactive updates.

These examples reflect the value of working with technology partners who understand both the technical and policy implications. If you’re considering a similar digital transformation, don’t hesitate to connect with AI implementation experts to explore what’s possible in your context.

Innovative AI Solutions

New AI solutions are pushing the boundaries of what’s possible in distribution. These innovations are transforming how companies operate, optimize, and serve customers.

Emerging technologies like digital twins are enabling real-time simulation of warehouse and transportation networks. Companies can test different layouts, policies, or delivery flows virtually before making changes in the real world. These AI-driven simulations reduce planning errors and improve strategic agility.

AI-powered vision systems are also evolving rapidly. Cameras integrated with AI can identify package damage, verify label accuracy, and track inventory levels in real time. These systems replace manual inspections, accelerating throughput and reducing costly errors.

Another rising trend is AI orchestration platforms, which act as central intelligence for all distribution activities. They connect demand planning, warehouse execution, transportation, and customer service. This end-to-end integration breaks down silos and enhances supply chain responsiveness.

AI‑Driven Innovations Transforming Distribution

Emerging Technologies in AI for Distribution

You’re operating in a world where digital speed and operational agility define success. Generative AI and computer‑vision are no longer experimental—they’re core tools driving distribution excellence. Generative AI systems can create demand forecasts, simulation scenarios, and even smart routing patterns. They leverage pattern recognition across sales data, weather trends, and logistics constraints to propose optimized strategies in human‑readable form. Early adopters across wholesale distribution report improvements in forecast accuracy and planning speed thanks to these tools—even in volatile markets.

On the visual front, computer vision is enabling real‑time quality control, inventory stock checks, and automated package sorting. AI‑driven cameras paired with deep‑learning models scan pallets, detect damaged goods, verify labels, and flag missing items. This reduces manual audits, speeds up throughput, and lowers error rates—even in sprawling warehouses collecting millions of scan events per day. Leading retailers and logistics hubs now rely on vision systems to sustain accuracy across high volume operations.

AI’s Role in Sustainability Efforts

Sustainability isn’t just good for the planet—it’s urgent for profitability. AI predictive analytics help you reduce waste by forecasting inventory demand more sharply, so overstock is minimized and spoilage avoided. In cold‑chain distribution, for example, Unilever credits a 10 % improvement in forecast precision in Sweden—aligning stock with demand and cutting markdown losses in perishables.

Smart systems are also optimizing energy usage across warehouses and trailers. AI algorithms adjust lighting, conveyor speeds, and refrigeration cycles based on throughput patterns and temperature sensors. This delivers tangible reductions in electricity and fuel usage, especially in cold storage environments where energy costs are high and efficiency directly supports margins.

These technological gains pair operational resilience with ESG strategy: lower carbon emissions, less waste, and smarter use of resources—all visible in measurable KPIs that appeal to eco-conscious partners and boards.

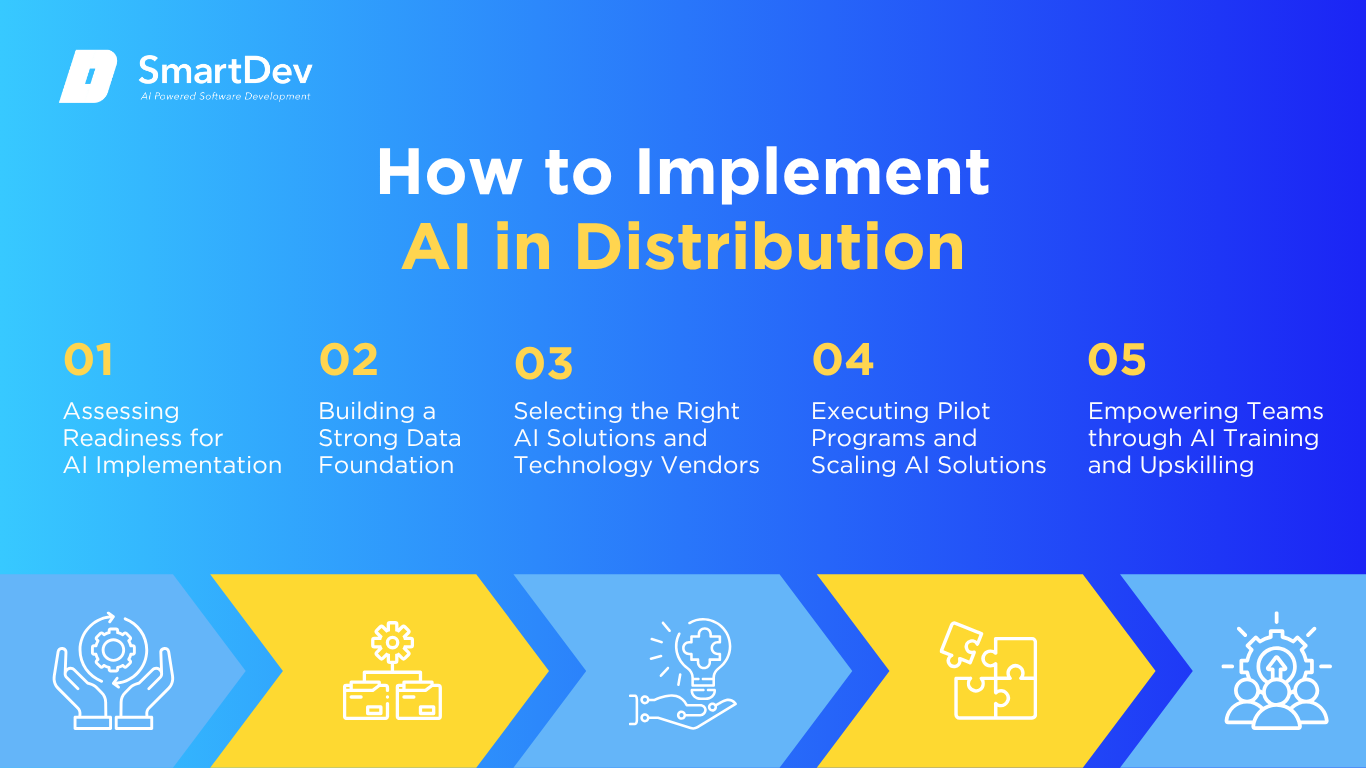

How to Implement AI in Distribution

Step 1: Assessing Readiness for AI Adoption

Step 1: Assessing Readiness for AI Adoption

To succeed, you first need clarity on whether your organization is AI‑ready. That starts with identifying high-impact areas—like demand planning, warehouse execution, or freight routing—where data volume is sufficient and business pain is acute. Look for workflows dominated by repetitive decisions, untapped data silos, or outdated planning tools. Selecting the right use cases helps you avoid the trap of chasing shiny solutions without measurable ROI.

Once areas are identified, assess your organizational maturity: Is data centralized? Do you have visibility across ERP, WMS, and TMS systems? How mature is your executive sponsorship and do you have leaders empowered to drive AI projects? Answering these questions gives you a clear roadmap on readiness—and helps you avoid investing in tools without infrastructure or strategic backing.

Step 2: Building a Strong Data Foundation

High-quality data is the lifeblood of AI. You’ll need to systematically collect, clean, and unify sources: transactional sales history, supplier lead times, vehicle telematics, temperature logs, customer support records—potentially millions of records across systems. Data governance is essential: defining ownership, standardizing formats, and setting access controls to ensure consistency and security as AI integrations launch.

Once data is cleansed and harmonized, you’ll integrate batches into AI platforms via ETL pipelines. Training machine‑learning models depends on clean, labeled data—e.g. past delivery success rates, inventory turn times, or device telemetry. You should build feedback loops: operational teams reviewing AI predictions, enhancing data understanding, and iterating models over time.

Step 3: Choosing the Right Tools and Vendors

The AI vendor landscape spans broad offerings and niche specialists. Some platforms deliver all-in-one solutions—demand forecasting, warehouse optimization, route planning—while others focus on one domain. When evaluating vendors, prioritize those with proven industry track records, transparent performance metrics, and integration capabilities with ERP/WMS/TMS.

Look for AI providers that support your scale, data volume, and cloud/on-prem balance. Strong vendor partnerships will offer pilot support, change management, and ongoing model refinement. Be wary of one-size-fits-all tools—you need customization to your unique distribution operations.

Step 4: Pilot Testing and Scaling Up

Start small. Pilot your chosen use case in a controlled environment—perhaps a single warehouse, route region, or product line with high volume and measurable outcomes. Design the test with clear success criteria: forecast accuracy uplift, error reduction rate, delivery time improvements, or inventory turns increased.

As you validate the ROI and operational impact, expand the models across sites and workflows. Use a gradual rollout to manage risk and maintain control. Feedback from early adopters should feed into each successive expansion—refining interfaces, adjusting thresholds, and improving predictions.

Step 5: Training Teams for Successful Implementation

AI implementation succeeds or fails at the human layer. You’ll need to invest in upskilling: train planners, warehouse operators, logistics teams, and customer service agents to understand outputs, challenge predictions, and feed real experiences back into models.

Develop change champions across functions—people who can bridge AI insights with day-to-day decisions. Executive support is essential: leaders must communicate how AI augments—not replaces—roles, fostering trust and engagement. When teams understand AI as a performance-enhancing tool, adoption accelerates and yields compound returns.

Whether you’re exploring your first pilot or scaling an enterprise-wide solution, our team is here to help. Get in touch with SmartDev and let’s turn your supply chain challenges into opportunities.

Measuring the ROI of AI in Distribution

Key Metrics to Track Success

When you adopt AI use cases in distribution, you’ll transform key performance indicators across operations. Productivity improvements emerge from faster decision cycles, fewer manual interventions, and better planning accuracy. Cost savings derive from reduced inventory holding, lower logistics overhead, and fewer service disruptions.

Keep a close eye on order fill rate improvements, year-over-year reductions in logistics spend, labor productivity gains per warehouse operator, and percentage reductions in emergency stockouts. Track changes in delivery accuracy, route cost per mile, and damage or return rates. These metrics enable evidence-based evaluation of AI’s impact across your organization—turning abstract value into boardroom-ready data.

Case Studies Demonstrating ROI

Consider McKinsey’s analysis of distributors embedding AI: they report inventory reductions of 20–30 %, logistics cost cuts between 5–20 %, and procurement savings of 5–15 %. That scale of impact translates into millions in capital efficiency gains for enterprises managing hundreds of millions in annual turnover. Demonstrated ROI helps justify investment.

Another case: a major building‑products distributor implemented a generative AI chatbot in their supply‑chain control tower to manage inventory across multiple warehouses. As a result, they improved fill rates by 5–8 % and significantly reduced analyst hours spent on manual reconciliation. That freed up teams to focus on supplier collaboration and strategic planning.

Uber Freight, leveraging AI-driven match and route optimization, reduced empty miles by 10–15 % and cut customer service wait times from five minutes to just 30 seconds through AI agentic service systems. This combination of operational efficiency and customer experience uplift drove measurable ROI in fuel savings and service quality.

Understanding ROI is possibly a challenge to many businesses and institutions as different in background, cost. So, if you need to dig deep about this problem, you can read AI Return on Investment (ROI): Unlocking the True Value of Artificial Intelligence for Your Business

Common Pitfalls and How to Avoid Them

Too often, AI investments flounder when businesses treat AI as a magic box rather than a structured initiative. One common pitfall is failing to align AI implementation with clear business goals—resulting in models that do not address real operational pain points. Avoid this by defining ROI metrics before you begin and choosing use cases tied to measurable improvements.

Another frequent issue is overreliance on under-cleaned or siloed data. Poor data quality leads to faulty predictions, undermining trust among users. Mitigate this risk by investing upfront in data cleansing, governance, and iterative data refinement.

Finally, many AI projects stall because organizations underestimate change management. Without engaged teams and a culture open to AI-augmented workflows, even high-performing systems can sit unused. Embedding executive sponsorship, transparent communication, and co-creation with frontline staff is essential to avoid this trap.

Future Trends of AI in Distribution

Predictions for the Next Decade

Predictions for the Next Decade

Over the next ten years, AI in distribution will evolve from operational optimization to strategic innovation. Expect widespread adoption of autonomous vehicles and drones for long-haul and last‑mile delivery, significantly reducing delivery time and cost across dense urban and remote areas. AI agents will increasingly simulate entire distribution networks—digital twins that test scenarios, configure layouts, and stress‑test logistics strategies virtually before committing physical changes.

AI models will also shift from descriptive and predictive analytics to prescriptive and agentic systems—automatically adjusting procurement, routing, staffing, and replenishment without human prompts. Generative AI will simulate unforeseen disruption scenarios and propose mitigations, embedding resilience directly into planning functions. Integration with blockchain-based smart contracts will enable real-time verifiable collaboration across suppliers, carriers, and distributors—enhancing trust and reducing execution lag.

How Businesses Can Stay Ahead of the Curve

To stay ahead, you must continually invest in data infrastructure and build agile teams that can rapidly test and adopt new AI tools. Maintain partnerships with AI innovators and solution providers who understand distribution complexities and offer transparent ROI tracking. Businesses should monitor industry benchmarks and pilot emerging technologies—e.g. drone delivery, VR/AR‑based training, or reinforcement learning algorithms for dynamic replenishment—to explore future upside.

A strategic approach: establish an innovation fund or COE (center of excellence) within your organization focused on AI experimentation. Empower cross-functional teams to run small pilots, measure impact, and scale successes. Keep executives and operational leaders aligned on vision, metrics, and resource prioritization so that innovation accelerates rather than stagnates.

Conclusion

Summary of Key Takeaways on AI Use Cases in Distribution

You’ve seen that AI use cases in distribution—notably demand forecasting, warehousing automation, predictive routing, maintenance alerts, fraud detection, and customer-service chatbots—are delivering measurable gains across inventory, logistics, labor, and service. When implemented thoughtfully, AI can reduce inventory by 20–30 %, slash logistics costs by roughly 5–20 %, and improve forecast accuracy by 10–30 % for major distributors.

The essential prerequisites are clear: strong data foundation, targeted pilot testing, vendor alignment, change management, and ROI-focused execution. With these in place, AI transforms distribution from reactive and inefficient to strategic, resilient, and growth‑oriented.

Call‑to‑Action for Businesses Considering AI Adoption

If you’re leading a mid‑ to large‑scale distribution operation, now is the time to act. Begin with identifying a high‑impact use case—perhaps demand planning, warehouse execution, or route optimization—and run a focused AI pilot with measurable goals. Invest in your data ecosystem, upskill your teams, and align AI implementation with strategic business metrics.

Establish a center of excellence if scale is your goal, and make innovation part of your operational DNA. With the right approach, AI becomes not just a tool for efficiency—but a cornerstone of competitive advantage in distribution.

Reference

- https://www.mckinsey.com/industries/industrials-and-electronics/our-insights/distribution-blog/harnessing-the-power-of-ai-in-distribution-operations

- https://www.mckinsey.com/industries/industrials-and-electronics/our-insights/distribution-blog/revolutionizing-sales-in-distribution-harnessing-the-power-of-ai

- https://wizcommerce.com/understanding-the-role-of-ai-in-distribution-process/

- https://www.proton.ai/blog/ai-in-distribution-how-artificial-intelligence-can-drive-growth

- https://definityfirst.com/blog/how-is-ai-transforming-the-distribution-industry

- https://www.dckap.com/blog/ai-in-distribution/

Definition of AI and Its Core Technologies

Definition of AI and Its Core Technologies 1. Intelligent Inventory Management

1. Intelligent Inventory Management 1. Fragmented Data Ecosystems

1. Fragmented Data Ecosystems 1. Demand Forecasting and Inventory Optimization

1. Demand Forecasting and Inventory Optimization Step 1: Assessing Readiness for AI Adoption

Step 1: Assessing Readiness for AI Adoption Predictions for the Next Decade

Predictions for the Next Decade