Introduction

Imagine knowing exactly where your products are, forecasting disruptions before they occur, and automatically optimizing your logistics operations. Artificial Intelligence (AI) isn’t just futuristic jargon; it’s reshaping supply chains today, making them smarter, faster, and more efficient. If you’re a supply chain leader, CTO, or innovation–driven executive, understanding how AI impacts logistics isn’t optional–it’s essential to staying competitive.

What is AI and Why Does It Matter in Supply Chain?

Illustration defining Artificial Intelligence and its role in supply chain management.

Illustration defining Artificial Intelligence and its role in supply chain management.

Definition of AI and Its Core Technologies

Artificial Intelligence (AI) refers to the ability of machines and systems to simulate human intelligence for tasks such as learning, reasoning, decision-making, and problem-solving. It enables organizations to process vast amounts of data, identify patterns, and make data-driven decisions with speed and accuracy-far beyond human capabilities.

At the core of AI are several key technologies:

- Machine Learning (ML): A method that enables systems to learn from historical and real-time data to improve predictions, detect anomalies, and automate decision-making.

- Natural Language Processing (NLP): Allows machines to interpret and generate human language, making it easier to extract insights from unstructured text such as supplier emails, contracts, and customer feedback.

- Computer Vision: Enables AI systems to analyze and interpret visual data, such as warehouse footage, product images, or scanned documents-critical for quality control and inventory tracking.

When applied to the supply chain, these technologies work together to optimize workflows, reduce operational risks, and improve visibility across every stage-from procurement and production to logistics and delivery. AI doesn’t just support efficiency; it empowers more agile, intelligent, and resilient supply chain ecosystems.

Want to explore how AI can transform your sector? Discover real-world strategies for deploying smart technologies in public systems-visit How to Integrate AI into Your Business in 2025 to get started today and unlock the full potential of AI for your business!

The Growing Role of AI in Transforming Supply Chain Management

Supply chains have always been complex, but globalization, consumer expectations, and recent disruptions-like the COVID-19 pandemic-have exposed their vulnerabilities. AI offers a solution by enhancing end-to-end visibility, predicting risks before they occur, and automating repetitive or error-prone processes. From warehouse robotics to intelligent transportation systems, AI is becoming the digital backbone of modern supply chains.

As McKinsey puts it, “Companies that aggressively digitize their supply chains can expect to boost annual growth of earnings before interest and taxes by 3.2%-the largest increase from digitizing any business area.”

Key Statistics and Trends Highlighting AI Adoption in Supply Chain Management

- According to Gartner, 75% of large enterprises will have adopted AI in their supply chain operations by 2026.

- A 2023 IBM report notes that businesses using AI-driven forecasting saw an 85% improvement in accuracy.

- Deloitte’s Global Chief Procurement Officer Survey found that AI implementation led to a 65% reduction in manual tasks in procurement functions.

- Capgemini research shows that AI applications in supply chain management can help companies reduce forecasting errors by up to 50% and reduce lost sales by up to 65%.

With these advantages, AI is no longer an experimental edge—it’s a core driver of resilience and performance.

Business Benefits of AI in Supply Chain Management

Artificial Intelligence is not just a technological upgrade—it’s a competitive advantage in modern supply chain management. From forecasting demand to delighting customers, AI enables faster decisions, leaner operations, and greater resilience across the value chain. Here’s how leading companies are turning AI into tangible results.

Key business benefits of AI adoption in supply chain management, including forecasting, visibility, cost reduction, efficiency, and customer experience.

Key business benefits of AI adoption in supply chain management, including forecasting, visibility, cost reduction, efficiency, and customer experience.

1. Improved Demand Forecasting

One of AI’s most valuable capabilities lies in its power to predict. By analyzing historical data, seasonal trends, external market signals, and real-time demand fluctuations, AI systems provide much more accurate forecasts than traditional models. This not only reduces inventory costs but also ensures you can meet customer expectations without overstocking. For example, Levi Strauss used AI-powered planning tools to achieve a 10% inventory reduction without impacting service levels.

2. Enhanced Supply Chain Visibility

Imagine having a live, panoramic view of your entire supply chain-from suppliers to end customers. AI tools connected with IoT sensors, GPS, and ERP systems make this a reality. Real-time updates on shipment status, location, and even temperature allow for quicker interventions and fewer disruptions. Cisco leverages AI to monitor its global supply chain and make instant decisions when bottlenecks or risks are detected, giving it a competitive edge.

Interested in how tech can bring real visibility to your supply chain? Check out how we helped a client build a secure, automated track & trace system that’s improving logistics in real time. Read the case study to see how it all came together.

3. Cost Reduction through Automation

Robotic Process Automation (RPA) paired with AI can automate mundane and repetitive tasks like invoice processing, order tracking, and data entry. At warehouses, AI-guided robots can pick, pack, and sort items with speed and precision, reducing labor costs. Ocado, a British online grocer, operates fully automated warehouses using AI-powered robots that handle over 50,000 orders per week, significantly cutting costs.

4. Increased Operational Efficiency

AI optimizes logistics by analyzing millions of variables to determine the best transportation routes, inventory placement strategies, and resource allocation. Dynamic route optimization considers real-time weather, traffic, and fuel prices, ensuring the most efficient delivery plan. DHL implemented an AI-based route planner that improved delivery speed by 15% and reduced fuel costs by 10%.

5. Better Customer Experience

From personalized product recommendations to real-time delivery updates, AI enhances customer satisfaction throughout the fulfillment journey. AI-enabled chatbots like those used by FedEx and UPS provide instant support for tracking inquiries and service issues, freeing up human agents for complex queries. Companies using AI in customer logistics are not only saving money but also building stronger loyalty.

Challenges Facing AI Adoption in Supply Chain Management

Key challenges faced when adopting AI in supply chain management, including data quality, costs, talent gaps, change management, and security.

Key challenges faced when adopting AI in supply chain management, including data quality, costs, talent gaps, change management, and security.

1. Data Quality and Management

Let’s face it-AI is only as good as the data you feed it. Poor-quality or inconsistent data can render even the most advanced algorithms ineffective. Many supply chain systems operate in silos, leading to fragmented and non-standardized data. Before you can expect reliable AI-driven insights, you need to lay a solid data foundation through improved governance, cleaning, and standardization processes.

2. High Implementation Costs

There’s no sugarcoating it: implementing AI can be expensive. The upfront investment often includes infrastructure upgrades, software licensing, training, and hiring new talent. For mid-sized and smaller businesses, this cost barrier can feel insurmountable. However, phased rollouts and pilot programs can help mitigate risk and demonstrate tangible ROI before going all in.

3. Skill Gaps and Talent Shortages

Even with the best tools in place, your AI initiative will fall flat without skilled professionals to manage and interpret the technology. The supply chain sector faces a growing talent gap in AI and data science. Upskilling existing employees and building strategic partnerships with AI vendors or consultancies is crucial for long-term success.

4. Organizational Resistance to Change

Technology may be ready, but people often aren’t. Resistance from employees-especially those worried about job security or those unfamiliar with digital tools-can derail AI projects. Transparent communication, clear role definition, and inclusive training programs can ease the transition and promote a culture of innovation.

5. Security and Privacy Risks

AI systems often process sensitive data, including customer information, supplier contracts, and proprietary logistics models. This makes cybersecurity a top concern. Without strong security protocols and real-time monitoring, your AI initiative could become a target for cyberattacks, eroding trust and potentially breaching regulatory compliance.

For those navigating these complex waters, a business-oriented guide to responsible AI and ethics offers practical insights on deploying AI responsibly and transparently, especially when public trust is at stake.

Specific Applications of AI in Supply Chain Management

AI is redefining the operational core of supply chains by enabling real-time visibility, proactive decision-making, and adaptive systems. Below are key applications of AI that illustrate how organizations are using this technology to reduce risk, optimize performance, and stay competitive in a fast-moving global market.

Key AI applications in supply chain management: predictive maintenance, autonomous vehicles, and intelligent inventory management.

Key AI applications in supply chain management: predictive maintenance, autonomous vehicles, and intelligent inventory management.

-

Predictive Maintenance: Minimizing Downtime, Maximizing Uptime

Predictive maintenance is one of the most impactful applications of AI in industrial supply chains. By combining AI with IoT-enabled sensors, companies can continuously monitor the condition of critical machinery and infrastructure-tracking variables like temperature, vibration, pressure, and usage patterns.

AI algorithms analyze this data to detect early warning signs of equipment failure and recommend maintenance before issues escalate. This proactive approach minimizes unplanned downtime, reduces costly repairs, and extends the operational lifespan of assets.

Real-world examples

Global companies like General Electric (GE) have embraced predictive maintenance in sectors such as aviation and energy. GE’s implementation resulted in a 40% reduction in unplanned downtime and generated millions in annual savings by avoiding emergency maintenance and lost productivity.

Similarly, Maersk, one of the world’s largest shipping firms, uses AI to predict maintenance needs across its cargo fleet. This allows the company to schedule servicing at optimal times, avoid delays at sea, and ensure smoother logistics operations with fewer disruptions.

-

Autonomous Vehicles in Logistics: Redefining Transport and Fulfillment

AI is at the heart of the autonomous vehicle revolution in logistics. Self-driving trucks, delivery drones, and autonomous mobile robots (AMRs) are being used to streamline both last-mile delivery and internal warehouse operations.

These systems rely on computer vision, LiDAR, GPS, and AI-powered decision engines to navigate routes, avoid obstacles, and operate continuously without human intervention. The result is increased safety, 24/7 availability, and greater operational efficiency.

Real-world examples

UPS has piloted autonomous freight trucks in partnership with TuSimple, running select long-haul routes in the U.S. These self-driving trucks have demonstrated improved fuel efficiency, optimized delivery schedules, and reduced reliance on human drivers-addressing a critical labor shortage in the logistics industry.

Meanwhile, Amazon’s Prime Air is developing drone delivery systems capable of transporting small packages in under 30 minutes. These drones use AI to plan flight paths, avoid hazards, and complete deliveries autonomously, redefining speed and flexibility in last-mile fulfillment.

-

Intelligent Inventory Management: Balancing Stock with Precision

Inventory management has traditionally been reactive, often relying on fixed reorder points or periodic reviews. AI enables a shift toward dynamic, predictive inventory control. By analyzing demand trends, supplier reliability, seasonal fluctuations, and market data in real time, AI systems can make intelligent decisions about when and where to replenish stock. This helps reduce both stockouts and excess inventory, leading to better working capital utilization and improved service levels.

Real-world examples

Walmart utilizes AI to manage its massive inventory ecosystem across thousands of stores. Its predictive models adjust restocking strategies in real time based on customer demand, supply chain delays, and regional trends. This has significantly reduced overstocks and improved on-shelf availability.

Zara, the global fashion retailer, applies machine learning to analyze in-store sales and online behavior, allowing it to adapt inventory levels at individual stores with remarkable precision. This responsive inventory system has helped Zara minimize markdowns, improve sell-through rates, and stay aligned with fast-changing fashion cycles.

Examples of AI in Supply Chain Management

Real-World Case Studies

Across industries, leading companies are using AI to solve long-standing logistical challenges, improve visibility, and enhance service delivery at scale. Below are three detailed examples that illustrate how AI is transforming supply chain operations from end to end.

1. Case Study 1: DHL – AI-Optimized Logistics for Global Freight Management

As one of the world’s largest logistics providers, DHL manages a vast network of distribution centers, delivery routes, and cross-border freight movements. With rising customer expectations and growing shipment volumes, DHL faced mounting pressure to improve delivery accuracy, reduce operating costs, and streamline warehouse operations-all while responding to real-time disruptions like weather events or customs delays.

To meet these challenges, DHL invested in AI-powered analytics and machine learning models. Within warehouses, AI was used to optimize pick-and-pack workflows, predict inbound and outbound order volumes, and dynamically assign labor based on activity forecasts. In transportation, route optimization engines analyzed traffic, fuel costs, and delivery urgency to create real-time routing recommendations.

The result was a 15% improvement in on-time deliveries and a double-digit reduction in operational costs across several regions. Moreover, predictive analytics enabled DHL to shift from reactive problem-solving to proactive management, allowing it to scale efficiently and respond rapidly to unexpected disruptions-making its global supply chain both leaner and more resilient.

2. Case Study 2: Coca-Cola – Real-Time AI for Global Demand Forecasting

With a presence in over 200 countries and a highly decentralized production network, Coca-Cola faced a growing challenge: how to manage fluctuating consumer demand while minimizing inventory imbalances and reducing waste across global markets. Traditional forecasting methods lacked the agility to respond to regional differences, seasonal changes, and unexpected shifts in buying behavior.

Coca-Cola turned to AI and real-time data analytics to modernize its supply chain planning. The company deployed machine learning models that continuously ingest data from POS systems, weather forecasts, social media sentiment, and historical sales. These models created hyper-local demand forecasts that allowed each bottling facility to plan more accurately based on region-specific trends.

The impact was substantial. Coca-Cola significantly reduced stockouts and overstocks across multiple product categories, while also optimizing production runs and transportation schedules. By aligning supply more closely with real-time demand, the company not only improved service levels but also reduced operational waste and enhanced agility across its global supply network.

3. Case Study 3: BMW – Smart Logistics and AI-Driven Quality Control in Manufacturing

In BMW’s high-precision manufacturing environment, maintaining quality across thousands of vehicle components and complex assembly workflows is both mission-critical and resource-intensive. Manual quality checks were time-consuming and vulnerable to inconsistencies, while real-time visibility into component movement and status across production sites was limited.

To address these pain points, BMW implemented AI-driven solutions within its logistics and quality assurance functions. Computer vision systems were introduced on assembly lines to inspect critical components-such as body panels, welding seams, and paint finishes-in real time. These systems could detect micro-defects invisible to the human eye and immediately alert technicians or trigger corrective actions. Simultaneously, AI-powered tracking systems monitored the flow of materials and components, predicting delays and optimizing parts delivery to each station.

The deployment resulted in a measurable drop in defect rates and a smoother, more synchronized production flow. With real-time anomaly detection and logistics optimization, BMW was able to accelerate manufacturing cycles, reduce waste, and ensure consistent product quality-all while enhancing traceability and transparency across its global production footprint.

Besides, if you are curious how leading companies are applying AI to solve real supply chain challenges? Discover how SmartDev helped build a bank-agnostic supply chain finance platform that streamlines operations, enhances transparency, and drives financial agility at scale. Read the full case study to see innovation in action.

Innovative AI Solutions

As supply chains become more complex and globalized, traditional tools alone can no longer keep up with the speed, scale, and volatility of modern operations. Emerging AI technologies—particularly Generative AI and Computer Vision—are pushing the boundaries of what’s possible, enabling businesses to move from reactive management to predictive and autonomous decision-making.

1. Emerging AI Technologies Being Applied in Supply Chain

Generative AI is gaining traction as a powerful tool for scenario planning and supply chain simulation. By using generative models, companies can create thousands of “what-if” scenarios to explore the impact of various disruptions-such as supplier failures, raw material shortages, transportation delays, or geopolitical instability-before they happen. These simulations help planners visualize consequences, compare mitigation strategies, and develop contingency plans in advance. Rather than relying on static, spreadsheet-based forecasts, generative AI enables dynamic modeling that adjusts to changing market variables and real-time inputs.

At the same time, computer vision is revolutionizing quality control and inspection processes across warehouses and manufacturing environments. Traditionally, visual inspections relied heavily on human labor, which is not only time-consuming but prone to error-especially under high-volume conditions. With AI-enabled vision systems, companies can monitor product quality continuously and with unmatched precision. These systems detect micro-defects, packaging inconsistencies, or incorrect labeling in real time, alerting technicians or automatically removing faulty products from the line before they reach the customer.

2. How These Solutions Are Transforming Business Operations

The operational impact of these technologies is substantial. Generative AI, for example, is enabling supply chain leaders to respond faster to volatility by replacing slow, manual planning cycles with continuous, AI-assisted forecasting. Unilever has adopted generative AI to simulate demand scenarios across global markets, helping its teams make more agile decisions about procurement, inventory, and production. This capability has become especially valuable in fast-changing environments, such as during the COVID-19 pandemic, where historical data alone was no longer a reliable planning input.

Meanwhile, Tesla leverages computer vision on its assembly lines to inspect vehicle components during production. These systems identify surface defects, alignment issues, and part mismatches instantly-ensuring that only flawless components move forward in the build process. This has allowed Tesla to reduce rework costs, shorten production cycles, and enhance product consistency across its high-volume manufacturing plants. Beyond just cost savings, these technologies elevate operational precision and support scalable growth without compromising on quality or speed.

Together, these innovations are redefining what it means to be agile and resilient in supply chain management. By proactively detecting risks and enabling smarter decision-making, they empower businesses to anticipate disruption, protect margins, and deliver better outcomes-faster.

AI-Driven Innovations Transforming Supply Chain Management

As supply chains become more complex and globalized, traditional tools alone can no longer keep up with the speed, scale, and volatility of modern operations.

Emerging AI technologies—particularly Generative AI and Computer Vision—are pushing the boundaries of what’s possible, enabling businesses to move from reactive management to predictive and autonomous decision-making.

-

Emerging Technologies in AI for Supply Chain

The next wave of transformation in supply chains is being driven by cutting-edge AI technologies. Generative AI, for instance, is no longer just for chatbots or content creation-it’s being deployed to simulate complex supply chain scenarios, helping companies make proactive decisions during disruptions. By generating simulations around raw material shortages or geopolitical risks, supply chain managers can identify the most effective contingency plans in advance.

On the visual side, computer vision is revolutionizing warehouse and quality control operations. Systems powered by computer vision can instantly detect defects, verify packaging compliance, or even track product movements using cameras and AI interpretation-at speeds and scales that humans simply can’t match.

-

AI’s Role in Sustainability Efforts

AI is also a powerful ally in achieving sustainability goals. Through predictive analytics, companies can align production more closely with actual demand, which minimizes waste and excess inventory. Smart sensors combined with AI help optimize energy usage in warehouses, factories, and transportation networks.

For example, Schneider Electric uses AI to analyze energy consumption patterns across its facilities. This has allowed the company to reduce energy usage by over 20%, demonstrating how AI can drive both environmental and financial performance. As ESG regulations grow stricter, AI’s ability to improve sustainability while maintaining efficiency will become even more critical.

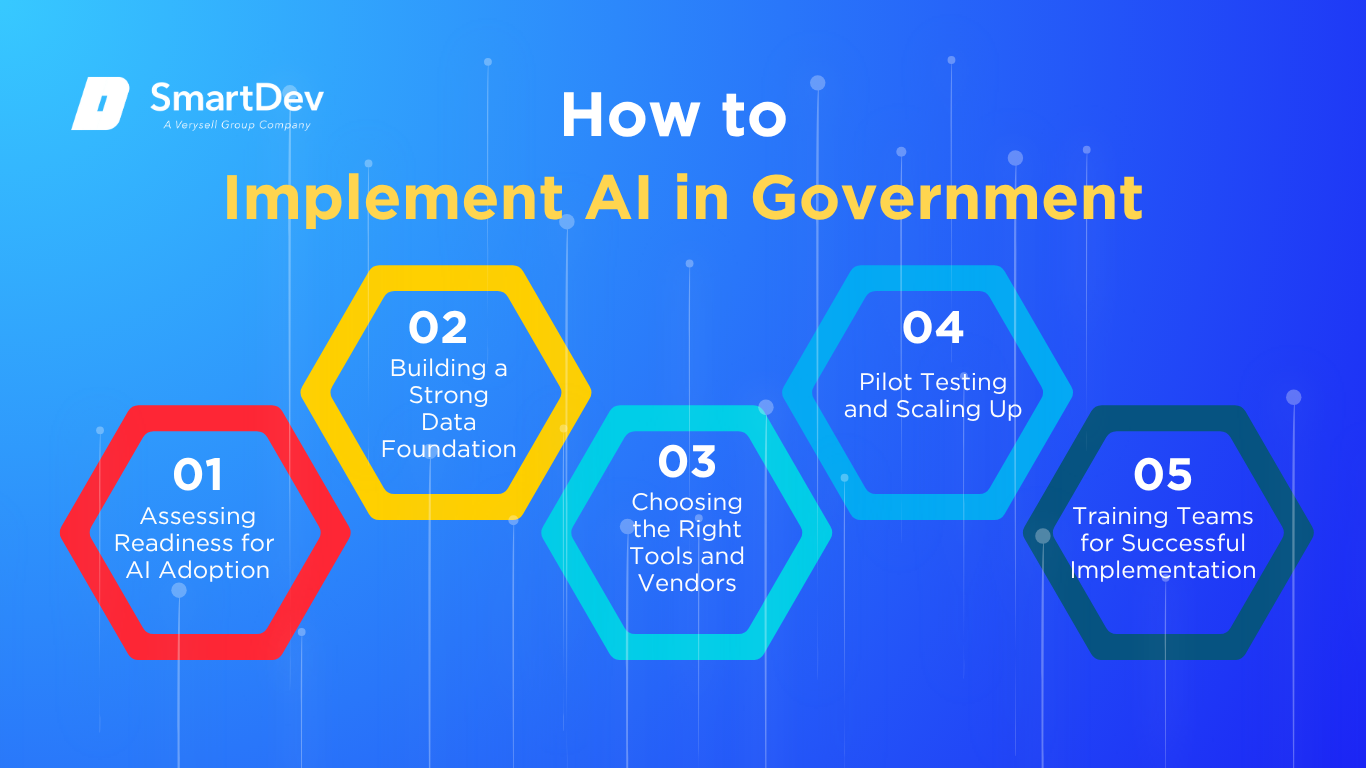

How to Implement AI in Supply Chain Management

-

Assessing Readiness for AI Adoption

Before diving into implementation, take stock of your organization’s current digital maturity. Are your data systems integrated? Is there executive support for innovation? Identifying the right use cases-those with high potential impact and available data-is crucial. Start with business areas where AI can solve specific pain points, such as excess inventory, inefficient routing, or inaccurate forecasting.

-

Building a Strong Data Foundation

Data is the lifeblood of AI. Ensure that your data is clean, complete, and consistently formatted. Break down silos between departments to create a centralized data repository. Establish governance practices for data quality, security, and compliance. The more accessible and standardized your data, the more value AI can deliver.

-

Choosing the Right Tools and Vendors

Not all AI tools are created equal. Look for solutions tailored to your industry with a proven track record in logistics and supply chain optimization. Whether you’re considering IBM Watson, Microsoft Azure AI, or specialized platforms like Llamasoft (a Coupa company), evaluate them based on integration capabilities, ease of use, scalability, and vendor support.

-

Pilot Testing and Scaling Up

Start small-launch pilot projects in one area of your supply chain to validate value and minimize risk. For example, test predictive maintenance on a single production line or deploy AI forecasting for one product category. Use the insights and ROI from these pilots to build a business case for broader rollout across your operations.

-

Training Teams for Successful Implementation

Technology is only one side of the equation; your people need to be ready too. Provide training on how to use AI tools, interpret insights, and collaborate with these systems. Encourage a mindset shift by highlighting how AI enhances roles rather than replacing them. Cross-functional collaboration between IT, operations, and business teams is essential for a successful rollout.

Whether you’re exploring your first pilot or scaling an enterprise-wide solution, our team is here to help. Get in touch with SmartDev and let’s turn your supply chain challenges into opportunities.

Measuring the ROI of AI in Supply Chain Management

As AI continues to reshape supply chain operations, quantifying its return on investment (ROI) becomes critical. Leaders need more than anecdotal evidence—they need measurable outcomes tied to efficiency, accuracy, cost savings, and customer satisfaction. Understanding how to evaluate, validate, and optimize AI initiatives is key to scaling success and sustaining competitive advantage.

-

Key Metrics to Track Success

To assess the ROI of AI in the supply chain, organizations should establish a clear set of performance indicators before implementation. Some of the most common and meaningful KPIs include forecast accuracy, inventory turnover, and order fulfillment rates. These metrics help determine whether AI is improving planning precision and aligning supply with actual demand. For example, an increase in forecast accuracy directly translates into better inventory positioning and fewer stockouts or excess inventory.

Beyond core operational metrics, companies should also measure the financial and process-driven impact. Cost-per-order, labor savings, and fuel consumption are tangible indicators of AI’s contribution to bottom-line improvements. In warehouse and fulfillment settings, AI-driven automation should be tracked through picking efficiency, error rates, and employee productivity.

In logistics, route optimization can be evaluated through reduced delivery times, lower fuel usage, and improved on-time performance. By capturing both efficiency and quality gains, businesses can build a comprehensive view of AI’s real value.

Understanding ROI is possibly a challenge to many businesses and institutions as different in background, cost. So, if you need to dig deep about this problem, you can read AI Return on Investment (ROI): Unlocking the True Value of Artificial Intelligence for Your Business

-

Case Studies Demonstrating ROI

Several organizations have already realized significant ROI from AI-driven supply chain transformation. Lenovo, for instance, implemented an AI-based demand sensing platform to improve planning accuracy and reduce excess inventory. By analyzing real-time sales, channel data, and market signals, the company achieved a 20% reduction in surplus inventory and a 25% improvement in forecast accuracy. These improvements not only freed up working capital but also enhanced supply chain responsiveness to market changes.

Another compelling case is Amazon, which has embedded AI across every layer of its supply chain-from robotic warehouse automation to predictive last-mile delivery routing. Through machine learning algorithms and real-time optimization, Amazon has dramatically reduced shipping delays, improved customer satisfaction scores, and saved billions in operational costs.

The company’s AI-driven warehouse systems, including predictive inventory placement and autonomous mobile robots, allow for faster picking and packing with minimal human intervention. These examples highlight how AI, when strategically deployed, drives both operational excellence and financial return at scale.

-

Common Pitfalls and How to Avoid Them

Despite the promise of AI, many organizations encounter roadblocks that can derail ROI. A frequent mistake is assuming AI is a plug-and-play solution. Without clean, integrated data and the right infrastructure, even the most advanced algorithms can fail to deliver meaningful insights.

Additionally, teams often underestimate the complexity of change management-particularly when introducing AI into roles traditionally handled by humans. Resistance from staff, lack of cross-functional collaboration, or unclear goals can stall momentum and limit adoption.

To avoid these pitfalls, companies should start with pilot programs tied to specific objectives and KPIs. Pilots help build internal credibility, demonstrate short-term wins, and identify gaps in data or process readiness. Executive sponsorship is also essential-AI initiatives must align with broader business strategy and have the support of leadership to overcome institutional inertia.

Finally, success hinges on setting realistic expectations and investing in training, communication, and stakeholder engagement. AI is not a one-time fix-it’s an evolving capability that requires continuous refinement, measurement, and iteration to drive sustained ROI.

Future Trends of AI in Supply Chain Management

-

Predictions for the Next Decade

Over the next ten years, Artificial Intelligence (AI) is poised to transition from a supportive operational tool to a central orchestrator of global supply chains. This evolution will be marked by several key developments:

Self-Healing Supply Networks: AI-driven systems will increasingly possess the capability to autonomously detect and rectify disruptions in real time. By leveraging predictive analytics and machine learning, these networks can anticipate potential issues-such as equipment failures or logistical bottlenecks-and implement corrective measures without human intervention.

Federated Learning Models: To address data privacy concerns, federated learning allows AI models to be trained across multiple decentralized devices or servers holding local data samples, without exchanging them. This approach enables collaborative model development while maintaining data confidentiality, facilitating cross-company cooperation in supply chain optimization.

Integration with Blockchain Technology: The convergence of AI and blockchain will enhance transparency and trust in supply chain transactions. Blockchain’s immutable ledger, combined with AI’s analytical capabilities, will ensure real-time tracking and verification of goods, particularly crucial in industries like food, pharmaceuticals, and luxury goods where provenance is essential.

These advancements signify that AI will no longer be a differentiator but a fundamental requirement for supply chain resilience and efficiency.

-

How Businesses Can Stay Ahead of the Curve

To remain competitive in this rapidly evolving landscape, organizations must adopt a proactive and holistic approach:

Strategic Integration of AI: Businesses should embed AI into their long-term strategic planning, ensuring that AI initiatives align with overarching goals and deliver measurable value. This involves identifying key areas where AI can drive improvements, such as demand forecasting, inventory management, and logistics optimization.

Cultivating an AI-Literate Workforce: Developing AI literacy across all organizational levels is critical. Training programs should be implemented to equip employees-from warehouse staff to executives-with the skills to understand and leverage AI tools effectively. A recent survey indicates that 74% of workers feel that a lack of training is hindering their ability to work with AI technologies.

Fostering a Culture of Innovation: Encouraging a mindset that embraces experimentation and iterative development is essential. Organizations should be willing to pilot cutting-edge technologies, learn from failures, and scale successful initiatives. Engaging in cross-industry partnerships can also provide access to diverse perspectives and expertise, accelerating innovation.

By focusing on these areas, businesses can not only adapt to the changing landscape but also position themselves as leaders in the next generation of supply chain management.

Conclusion

-

Summary of Key Takeaways on AI Use Cases in Supply Chain

Artificial Intelligence is no longer a future aspiration—it’s a present-day imperative. From predictive maintenance and intelligent inventory management to autonomous logistics and real-time quality control, AI is transforming supply chain operations across every sector. These innovations are driving measurable gains in efficiency, accuracy, sustainability, and customer satisfaction. The benefits aren’t theoretical—they’re happening today, in warehouses, on production lines, and in global distribution networks.

What these use cases reveal is clear: AI offers scalable, actionable solutions to some of the most pressing challenges in supply chain management. Whether you’re dealing with legacy inefficiencies, supply volatility, or rising customer expectations, AI empowers you to respond with speed and precision. The organizations succeeding with AI aren’t just adopting new tools—they’re embracing a mindset of continuous innovation, backed by strategic execution and data-driven decisions.

-

Call-to-Action for Businesses Considering AI Adoption

If you’re thinking about AI, the best time to start is now. Begin by identifying high-impact areas in your supply chain where AI can deliver immediate value—be it forecasting, automation, or visibility. Build a strong foundation by investing in the right data infrastructure and empowering your teams with the training and tools they need to succeed. Pilot projects that solve specific pain points can build momentum and lay the groundwork for scalable transformation.

At SmartDev, we specialize in helping organizations unlock the full potential of AI in supply chain operations. Ready to bring AI into your supply chain? Let SmartDev help. Start with a tailored pilot today.

—

References:

- What is AI in supply chain management?

- Top 15 Real-Life Use Cases For AI In the Supply Chain Industry

- 7 generative AI use cases in supply chain

- Top 20 AI in Supply Chain Examples: Applications in the Industry

- How supply chains benefit from using generative AI

- AI in Supply Chain: How Supply Chains Benefit from AI

- What is AI in supply chain?

- Supply Chain AI: 25 Current Use Cases (and A Handful Of Future Ones)