Introduction

Fast-moving consumer goods (FMCG) companies face relentless pressure: slim margins, volatile demand, and increasingly demanding consumers. AI is emerging as a game-changer, automating supply chains, fueling product innovation, and delivering highly targeted marketing with surprising speed.

This in-depth guide explores how AI is driving real-world impact across FMCG from boosting operational agility and sustainability to reshaping customer interactions, while highlighting implementation challenges and practical strategies.

What is AI and Why Does It Matter in FMCG?

Definition of AI and Its Core Technologies

AI refers to the simulation of human intelligence processes by machines, particularly computer systems. These processes include learning (gathering and applying data), reasoning (drawing conclusions from patterns), and self-correction. Foundational AI technologies such as machine learning (ML), natural language processing (NLP), and computer vision allow systems to process large-scale data, recognize consumer trends, and make real-time decisions with minimal human intervention.

AI refers to the simulation of human intelligence processes by machines, particularly computer systems. These processes include learning (gathering and applying data), reasoning (drawing conclusions from patterns), and self-correction. Foundational AI technologies such as machine learning (ML), natural language processing (NLP), and computer vision allow systems to process large-scale data, recognize consumer trends, and make real-time decisions with minimal human intervention.

In the FMCG sector, AI is applied to automate and optimize a wide range of functions, from demand forecasting and inventory management to consumer insights and personalized marketing. ML models predict future buying behavior, computer vision monitors shelf stock levels, and NLP tools analyze product reviews and social sentiment. Together, these tools help FMCG companies enhance operational agility, innovate faster, and deliver tailored consumer experiences.

The Growing Role of AI in Transforming FMCG

AI is transforming FMCG from a reactive supply-driven model to a dynamic, data-powered ecosystem. Companies are no longer limited to historical sales data and manual processes, AI systems can detect emerging trends, forecast demand spikes, and adjust production or distribution strategies accordingly. This shift enables brands to respond faster to market changes and reduce waste through more precise planning.

In addition, AI empowers FMCG teams with deeper, real-time consumer insights. Platforms that analyze customer reviews, social media, and purchase behavior help marketers tailor messaging and promotions to specific audience segments. This level of personalization improves conversion rates and builds brand loyalty in an increasingly competitive landscape.

Key Statistics and Trends Highlighting AI Adoption in FMCG

AI adoption in FMCG is accelerating as companies seek more predictive and personalized strategies. A recent McKinsey report shows that AI can reduce forecasting errors in supply chains by up to 50%, which directly translates into lower stockouts and better inventory management. These results are pushing more FMCG firms to embed AI across their operations.

The potential for efficiency and innovation is significant. Deloitte notes that early AI adopters in FMCG have seen up to a 20% reduction in supply chain costs and a 30% improvement in speed to market for new product launches. These gains make AI not just a tech upgrade but a strategic differentiator.

The market outlook is robust. According to Market.us, the global AI in FMCG market is expected to reach $57.7 billion by 2033, growing at a CAGR of 22%. As AI capabilities evolve, companies will increasingly rely on intelligent systems for everything from product development to hyper-personalized engagement strategies.

Business Benefits of AI in FMCG

AI is solving critical business challenges in the FMCG sector, ranging from supply chain inefficiencies and lost revenue from poor forecasting to low ROI in marketing spend. Below are five key benefits where AI delivers tangible, enterprise-level value:

1. Enhanced Demand Forecasting and Inventory Optimization

1. Enhanced Demand Forecasting and Inventory Optimization

AI models apply machine learning to synthesize diverse data, such as historical sales, promotions, local events, and weather to produce highly accurate demand forecasts. These systems continuously learn and adapt, enabling FMCG companies to predict demand spikes or declines with greater precision and agility.

This minimizes stockouts and overstock situations, reducing lost sales and excess inventory holding costs. With more reliable forecasts, companies can streamline replenishment, improve service levels, and maintain leaner, more efficient supply chains.

2. Accelerated Product Innovation

AI tools process consumer reviews, social media chatter, and competitive trends to uncover product gaps and emerging preferences. This allows R&D teams to make data-backed decisions on which features, formats, or flavors to pursue before consumer needs become obvious in sales data.

As a result, FMCG brands can launch products faster and with higher success rates. AI reduces the trial-and-error cycle in innovation, ensuring that investments are focused on concepts with clear market demand and reducing the risk of underperforming SKUs.

3. Hyper-Personalized Marketing

Using behavioral data and real-time analytics, AI segments consumers at a granular level based on preferences, purchasing habits, and online interactions. Campaigns can then be dynamically adjusted for each audience group, down to the individual level.

This leads to more relevant communications and higher engagement, ultimately increasing conversion rates and customer lifetime value. FMCG brands gain the ability to execute personalization at scale—without the manual lift typically required.

4. Operational Efficiency and Cost Savings

AI automates routine processes across manufacturing, procurement, and logistics, such as scheduling, demand planning, and route optimization. These efficiencies reduce human error, speed up decision-making, and lower overall operational costs.

In manufacturing, predictive maintenance powered by AI prevents downtime by identifying equipment failures before they happen. This proactive approach cuts repair expenses and avoids costly production delays, leading to more consistent output and improved margins.

5. Stronger Consumer Loyalty

AI enhances consumer experiences by personalizing interactions across digital and physical touchpoints. Tools like chatbots, recommendation engines, and sentiment analysis platforms make each interaction more relevant and responsive to individual needs.

This boosts satisfaction and builds emotional connections with the brand. Over time, these tailored experiences drive repeat purchases, positive word-of-mouth, and stronger loyalty in a competitive FMCG landscape.

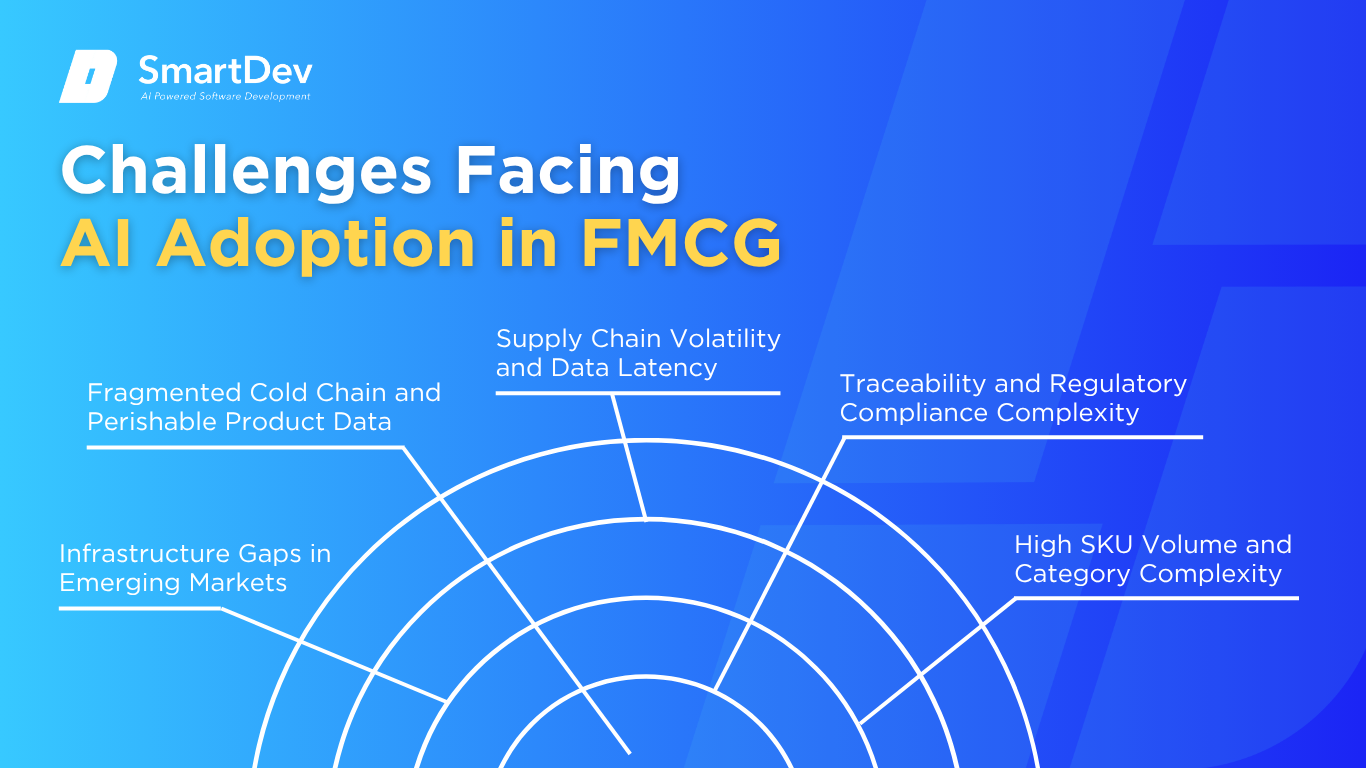

Challenges Facing AI Adoption in FMCG

Fragmented Cold Chain and Perishable Product Data

Fragmented Cold Chain and Perishable Product Data

FMCG companies, particularly those dealing with perishable goods or cold-chain logistics, face fragmented data across supply points like farms, warehouses, refrigerated trucks, and retail shelves. Sensor data on temperature, expiry, or transit conditions is often isolated or delayed, making it hard to train real-time AI models for spoilage prediction, dynamic pricing, or waste reduction.

Solving this requires IoT integration and real-time data architecture across the entire cold chain. Without synchronized, high-fidelity data inputs, AI tools will underperform—missing critical events that lead to stock losses or compliance failures. Bridging this data gap is essential for accurate forecasting and sustainability in perishable product segments.

Traceability and Regulatory Compliance Complexity

FMCG products, especially food, cosmetics, and pharmaceuticals, are subject to strict traceability and safety regulations. However, data supporting compliance (e.g., sourcing, quality audits, shelf-life testing) is often stored in disparate formats across internal systems and third-party vendors. This undermines AI’s ability to automatically flag non-compliance or optimize sourcing based on risk.

To address this, companies must digitize and unify their compliance documentation, potentially integrating blockchain or AI-powered document analysis tools. Without clear traceability, AI can misclassify risks or fail to catch regulatory breaches – posing reputational and legal risks for global FMCG brands.

Infrastructure Gaps in Emerging Markets

Many FMCG companies rely heavily on growth in emerging markets, but these regions often lack the digital infrastructure required for AI, such as consistent internet connectivity, cloud services, or IoT coverage. Data collection from distributors, mom-and-pop stores, or local warehouses is inconsistent or manual, reducing AI’s reach and reliability.

To fully unlock AI’s potential, companies must invest in mobile-friendly tools, localized data pipelines, and lightweight AI models that work with limited connectivity. Ignoring these infrastructure constraints limits innovation to mature markets – undermining AI’s role in global expansion and inclusive strategy execution.

Supply Chain Volatility and Data Latency

The FMCG sector is highly sensitive to global disruptions like climate events, geopolitical tensions, or pandemics, which rapidly alter supply chain conditions. Yet many firms still rely on periodic data refreshes or manual inputs, preventing AI from responding to disruptions in real-time. This latency renders predictive models outdated when agility is most needed.

Building resilient AI systems requires real-time data ingestion and adaptive learning capabilities. FMCG firms must transition from static forecasting to AI that evolves with market shocks. Without this shift, AI risks offering false confidence rather than actionable foresight during supply chain crises.

High SKU Volume and Category Complexity

FMCG companies manage thousands of SKUs across fast-moving, seasonal, and region-specific products. Training AI to optimize pricing, promotions, or assortments across this volume, while factoring in cross-elasticities, regional trends, and competitor moves is enormously complex. Errors in one segment can ripple across portfolios, harming profitability.

Addressing this requires deep integration between category managers and AI teams to align models with business logic and ground-level realities. If AI is treated as a one-size-fits-all tool, it will fail to capture the nuanced decisions that drive FMCG performance—leading to poor adoption and trust issues at the commercial level.

Specific Applications of AI in FMCG

1. AI‑Powered Demand Forecasting

1. AI‑Powered Demand Forecasting

AI‑powered demand forecasting applies machine learning algorithms to predict future product demand, solving the problem of inventory imbalances in FMCG supply chains. These models ingest historical sales data, promotional schedules, seasonal patterns, and factors like weather or local events. Integrated with ERP and supply chain systems, they automate ordering and production planning.

Demand forecasting improves cash flow, reduces waste, and enhances service levels by minimizing stockouts and overstock. The strategic value also includes agility in response to market shifts. However, it requires high-quality data ingestion and seamless integration with legacy systems.

Technical considerations include regular model retraining to adapt to changing buying trends and comprehensive data governance. Scalability is vital to handle demand variance across multiple SKUs and regions. Data security is also important, especially when using external data sources.

Real-World Example:

Procter & Gamble implemented an AI forecasting system using Azure ML that processed retail POS and internal sales data. The system led to a 15% drop in stockout rates and a 10% reduction in inventory carrying costs. Forecast accuracy improved by over 20%, driving better supply chain performance.

2. AI‑Driven Consumer Sentiment Analysis

NLP‑based consumer sentiment analysis processes unstructured text from social media, product reviews, and customer feedback to identify brand perception and emerging issues. Models detect sentiment polarity, key topics, and emotional tone to aid marketing strategy decisions. Integrated into CRM and marketing dashboards, these insights trigger timely actions.

This application accelerates response to negative sentiment and fine-tunes messaging based on consumer trends. It enhances brand reputation and informs product innovation. However, it faces challenges like handling slang, sarcasm, and multilingual text.

Ensuring representative data from diverse sources is vital to avoid skewed insights. Regular model updates and human-in-the-loop validation help maintain accuracy. Privacy compliance must be considered when monitoring consumer conversations.

Real-World Example:

Unilever used AWS Comprehend to analyze social media sentiment around new ice-cream flavors. They achieved a 20% higher flavor acceptance rate by refining products pre-launch. Campaign messaging was optimized based on sentiment trends, improving engagement.

3. AI‑Enhanced Pricing Optimization

AI‑enhanced pricing uses machine learning and reinforcement learning to dynamically adjust prices based on demand elasticity, competitor pricing, and inventory levels. Models draw on historical sales, competitor feeds, and promotional strategies, feeding insights to pricing engines and dashboards. Integration with e-commerce and in-store pricing systems enables real-time updates.

The strategic benefit includes optimized margins, improved competitive positioning, and the ability to test pricing strategies quickly. It also supports personalized promotions and segmented price targeting. Ethical considerations include maintaining transparency and avoiding consumer exploitation.

Operational challenges include ensuring pricing changes don’t disrupt retailer agreements and aligning with legal pricing guidelines. Ongoing calibration helps models respond to seasonality and changing consumer behavior. A/B testing validates model outputs before broad rollout.

Real-World Example:

Nestlé deployed a TensorFlow-based dynamic pricing engine for both e-commerce and brick-and-mortar products. They saw a 5% increase in gross margin and 3% revenue growth from mid-pilot. The system allowed nimble pricing adjustments during promotional events without sacrificing volume.

4. Intelligent Logistics & Route Optimization

AI-powered route optimization uses graph algorithms and machine learning to plan FMCG distribution routes based on order volumes, vehicle capacities, delivery windows, and real-time traffic. It ingests GPS, telematics, and historical delivery data, then suggests optimized routes to fleet management platforms. Results are updated dynamically to adapt to delays.

This increases delivery efficiency, reduces fuel consumption, and improves customer satisfaction through faster, on-time deliveries. It also enables better fleet utilization and lowers carbon emissions. However, it requires robust real-time data connectivity with vehicles and warehouses.

Scalability is key to manage large distribution networks with varying capacity constraints. Integration with existing TMS and handling data latency can be challenging. Continuous route simulation ensures adaptation to varying demand and traffic patterns.

Real-World Example:

Coca‑Cola implemented route-optimization model across its APAC logistics network. Delivery times reduced by 12% and fuel usage dropped 8%. On-time delivery performance improved by 6%, boosting customer satisfaction.

5. AI‑Enabled Computer Vision Quality Control

Computer vision systems with deep learning inspect packaging and product lines for defects, mislabeling, or foreign objects in real time. High-resolution images are processed by convolutional neural networks to detect anomalies and flag issues to operations staff. The systems operate inline at production speeds.

Quality control improves consistency, reduces waste, and enhances safety compliance. Automated inspection minimizes human error and supports high-speed production. Technical challenges include ensuring diverse training datasets and managing variations in lighting.

System calibration is essential for different packaging types and line speeds. Regular retraining is required to adapt to new products or formats. Infrastructure reliability and maintenance are vital to prevent inspection downtime.

Real-World Example:

Kellogg’s implemented NVIDIA Jetson-powered vision systems to detect misprints on cereal boxes. They reduced packaging defects by 30% and cut quality-control labor costs. The system also helped avoid costly product recalls related to labeling errors.

6. Personalized Marketing with Predictive Targeting

AI-powered predictive targeting uses clustering, collaborative filtering, and deep learning to create personalized marketing campaigns for FMCG consumers. These models analyze purchase history, demographic data, and online behavior to predict preferences. Insights feed into CRM, email marketing, and programmatic ad platforms for targeted messaging.

Personalization increases campaign engagement, boosts brand loyalty, and drives higher conversions by offering relevant content to consumers. It also enables real-time adjustments based on performance metrics, optimizing ROI. Regulatory compliance is crucial, requiring explicit consumer consent for data use.

Privacy and security frameworks must ensure data handling transparency and opt-ins. Continuous A/B testing refines messaging and targeting effectiveness. Ethical data stewardship builds consumer trust over time.

Real-World Example:

Danone used Google AI tools to segment yogurt consumers and deliver personalized ads across digital channels. They achieved a 40% increase in click-through rates and a 7% lift in incremental sales. Real-time optimization enabled ongoing campaign refinement.

Examples of AI in FMCG

Examples of AI in FMCG

Real-World Case Studies

1. Procter & Gamble: Transforming Supply Chains with AI Forecasting

To overcome persistent issues with demand unpredictability and inventory inefficiencies, Procter & Gamble turned to AI-powered demand forecasting. The goal was to enhance supply chain agility by integrating real-time data from retail partners, distributors, and internal operations into predictive models. These AI systems aimed to reduce manual forecasting errors and enable dynamic planning across regional markets.

The forecasting model, built on Azure Machine Learning, analyzed vast datasets including POS data, promotional activity, and external factors like weather. It continuously refined predictions through machine learning feedback loops and enabled the company to automate production schedules and order fulfillment. The solution integrated directly with their supply chain systems, enabling proactive rather than reactive decisions.

Following implementation, P&G reduced stockouts by 15% and cut expedited shipping costs by 12%, while inventory turnover improved by 8%. Forecast accuracy jumped by over 20%, supporting more precise manufacturing and distribution alignment. This case highlights the power of predictive AI in solving traditional supply chain pain points and setting a new standard for operational efficiency in FMCG.

2. Nestlé: Leveraging AI for Dynamic Pricing

Nestlé faced a major challenge in adapting to competitive pricing fluctuations and seasonal consumer behavior in real-time. Legacy systems were too rigid, resulting in missed revenue opportunities during promotional windows and inefficiencies in price setting across diverse markets. To address this, Nestlé launched a dynamic pricing initiative powered by AI to optimize price decisions based on demand and market signals.

Using TensorFlow-based models, the pricing system continuously analyzed historical sales data, competitor prices, and promotional calendars to recommend pricing actions. It enabled real-time price adjustments across both e-commerce platforms and brick-and-mortar channels. Pricing managers accessed model recommendations via intuitive dashboards, enhancing decision speed and accuracy.

The results were notable: gross profit margins increased by 5% and revenue rose by 3% in test markets, all without reducing sales volumes. Teams also reported faster campaign execution and better ROI on discounts. Nestlé’s case illustrates how AI can inject agility into traditionally static pricing models and directly impact financial performance.

3. Coca-Cola: Optimizing Logistics with AI Routing

Coca-Cola encountered recurring inefficiencies in its delivery network, particularly in congested urban regions across APAC. Traditional routing systems struggled to keep up with the complexity of real-time traffic, fleet capacity, and delivery constraints. The company needed a smarter logistics solution to reduce delays, cut fuel usage, and improve service levels to retail partners.

To tackle this, Coca-Cola integrated AI-based route optimization using HERE Maps APIs and in-house telematics. The system dynamically recalculated optimal delivery routes based on live traffic, weather, vehicle capacity, and order urgency. It provided dispatchers and drivers with adaptive route plans, improving reliability and reducing variability in delivery performance.

Post-implementation, Coca-Cola reported a 12% reduction in average delivery time and an 8% decrease in fleet fuel consumption. On-time delivery rates improved by 6%, contributing to better retailer satisfaction and lower logistics costs. This case demonstrates how AI can modernize traditional logistics and unlock measurable efficiency gains in FMCG distribution.

4. Danone: Personalized Consumer Engagement through Predictive Targeting

Danone faced challenges in scaling personalized marketing across its diverse product lines and customer segments. Traditional campaigns lacked precision and failed to reflect individual consumer preferences, leading to lower engagement and inefficient ad spend. The company needed a solution to deliver targeted, data-driven marketing that could adapt to consumer behavior in real time.

To address this, Danone adopted an AI-driven predictive targeting platform using Google Cloud tools. The system analyzed historical purchase patterns, browsing behavior, and demographic data to create micro-segments and deliver personalized messaging across digital channels. AI models continuously learned from campaign performance to optimize delivery and maximize relevance.

The campaign resulted in a 40% increase in click-through rates and a 7% lift in incremental sales for targeted yogurt products. Consumer feedback indicated higher satisfaction due to more relevant offers and content. Danone’s success illustrates how AI can elevate customer experience and maximize marketing efficiency in FMCG.

Innovative AI Solutions

Many FMCG brands are now deploying AI-powered robotics in fulfillment centers to address labor shortages and accelerate order processing. These systems, equipped with computer vision and lidar, autonomously identify, pick, and move products, eliminating the need for manual intervention. With integration into warehouse management systems, they enable real-time inventory updates and seamless coordination between logistics and supply chain functions.

In manufacturing, predictive maintenance is being revolutionized by edge AI, which processes sensor data directly on factory floors. By monitoring machine vibration, temperature, and acoustic signals, AI models can forecast failures and recommend preemptive maintenance actions. This shift has helped manufacturers reduce downtime by up to 25%, extend equipment lifespan, and improve overall plant efficiency.

On the consumer front, FMCG companies are embracing conversational AI to deliver responsive, personalized support via chatbots and voice assistants. These AI systems handle common queries, guide product discovery, and support reordering, available 24/7 across multiple platforms. The result is faster response times, up to a 30% reduction in call center volume, and improved customer satisfaction in digital environments.

AI-Driven Innovations Transforming FMCG

Emerging Technologies in AI for FMCG

Generative AI in Marketing and Packaging

Generative AI is helping FMCG brands transform creative workflows by generating personalized ads, product packaging, and content at scale. Brands like Coca-Cola and Nestlé are already experimenting with generative AI to co-create campaigns, using tools like OpenAI and Canva’s AI integrations.

Beyond content, generative AI is being used to simulate and test packaging designs that resonate with local markets. This helps companies meet consumer preferences faster and more cost-effectively. The ability to localize and personalize experiences gives FMCG brands a major edge in competitive retail environments.

Computer Vision in Retail and Production

Computer vision enables real-time insights on product quality and shelf management in retail and manufacturing. These technologies reduce lost sales due to out-of-stock products and improve merchandising consistency.

In production environments, AI cameras detect packaging defects or labeling errors before products leave the line. This minimizes recalls and enhances customer satisfaction. It also helps reduce waste and quality-related returns, improving both operational efficiency and sustainability.

AI’s Role in Sustainability Efforts

Minimizing Waste with Predictive Intelligence

AI is playing a pivotal role in reducing waste across the FMCG supply chain by making demand forecasting more accurate. These predictive tools help balance supply with actual consumption, slashing unnecessary production. The result is a leaner, more sustainable model that cuts costs while supporting eco-conscious goals.

Greener Operations Through AI-Powered Energy Management

AI-driven systems are optimizing energy use in FMCG factories, warehouses, and logistics by adjusting operations in real-time. In logistics, AI is used to plan shorter delivery routes and consolidate shipments, lowering fuel consumption and emissions.

By integrating these tools, FMCG players are reducing carbon footprints while maintaining high delivery performance. Sustainability targets are met without sacrificing business goals or product availability.

How to Implement AI in FMCG

Step 1. Assessing Readiness for AI Adoption

Step 1. Assessing Readiness for AI Adoption

Before adopting AI, FMCG companies need to assess which parts of their operations can benefit most from intelligent automation. Common areas include demand forecasting, inventory planning, route optimization, and product personalization. Identifying pain points such as stockouts, high return rates, or manual processes helps clarify where AI will have the highest impact.

It’s also critical to evaluate the company’s digital maturity and infrastructure. Teams must ensure their systems can integrate with AI tools and that they have reliable access to relevant data sources like POS data, ERP logs, and consumer feedback. Without this foundation, even the most advanced AI tools won’t deliver meaningful results.

Step 2. Building a Strong Data Foundation

AI thrives on quality data, making strong data management practices essential for FMCG businesses. This means consolidating sales, logistics, marketing, and inventory data into centralized systems, while cleaning and formatting it to remove inconsistencies. Clean data improves the accuracy of AI predictions and reduces the risk of flawed decision-making.

In addition, implementing clear data governance policies ensures compliance with privacy laws and internal security standards. Regular updates and validation of data sets are crucial to keeping AI models aligned with real-world business changes. This foundation is what turns raw information into actionable insights.

Step 3. Choosing the Right Tools and Vendors

Selecting the right AI platforms depends on your FMCG company’s size, goals, and specific challenges. Whether it’s a tool for supply chain visibility, customer analytics, or visual merchandising, compatibility with existing tech infrastructure is key. Brands should prioritize solutions that are scalable, easy to integrate, and backed by strong customer support.

Working with experienced vendors who understand FMCG dynamics can greatly smooth the onboarding process. Look for partners with proven case studies in your industry and flexible tools that adapt to your workflows. A well-matched vendor can accelerate implementation and drive early wins.

Step 4. Pilot Testing and Scaling Up

Starting with a small pilot project helps FMCG companies understand the real-world performance of AI tools without major risk. For instance, a business might test AI demand forecasting in one region before rolling it out nationally. This trial period helps iron out technical issues, calibrate algorithms, and evaluate ROI.

Once validated, companies can develop a broader roadmap for scaling AI across product lines or geographies. This includes setting clear benchmarks, training teams on new workflows, and allocating budgets for phased expansion. A structured rollout ensures adoption is smooth and sustainable.

Step 5. Training Teams for Successful Implementation

AI adoption in FMCG isn’t just a technical challenge—it’s a people one too. Training teams to understand how AI works and how to use it effectively ensures smoother integration and faster value realization. Employees should be taught how to interpret AI-generated insights and adapt workflows accordingly.

Ongoing education, including workshops and digital learning, helps staff stay up to date as tools evolve. Cultivating a mindset of curiosity and innovation will encourage teams to embrace AI as a partner rather than a threat. This cultural shift is key to unlocking long-term competitive advantage.

Measuring the ROI of AI in FMCG

Key Metrics to Track Success

Measuring the return on AI investment in FMCG begins with tracking productivity, operational costs, and inventory efficiency. AI tools in forecasting, warehouse automation, and quality control speed up operations, reduce errors, and cut down on labor hours. This translates into faster time-to-market and fewer lost sales due to stockouts or spoilage.

Financially, companies report lower logistics costs, higher sell-through rates, and improved marketing ROI from personalized campaigns powered by AI. For instance, AI-driven demand forecasting minimizes overstock and markdowns, protecting margins and optimizing working capital. These savings directly boost profitability while improving supply chain agility.

Case Studies Demonstrating ROI

Coca-Cola leveraged AI to optimize their digital marketing campaigns, resulting in a 4X increase in ROI by targeting micro-audiences with personalized content. Meanwhile, Nestlé implemented AI-driven factory automation and predictive maintenance, reducing unplanned downtime and saving millions in operational costs. These initiatives helped streamline their global supply chain while enhancing production consistency.

Another example is PepsiCo, which used AI-powered shelf-monitoring to reduce out-of-stock incidents by over 30% in select markets. By integrating real-time image recognition with retail analytics, they not only increased sales but also improved retailer relationships. These results prove that AI investments deliver both top-line growth and bottom-line savings when aligned with business goals.

Common Pitfalls and How to Avoid Them

One common mistake in FMCG AI adoption is underestimating the importance of clean, high-quality data. Poor data can mislead AI models, resulting in flawed forecasts, inaccurate targeting, or inefficient logistics decisions. Companies must prioritize data governance and invest in systems that ensure continuous data validation.

Another issue is implementing AI in silos without full organizational alignment. Teams may resist new tools if not trained properly, or decisions may be made without cross-functional input. To avoid this, FMCG leaders should create cross-team AI strategies and ensure clear communication, training, and oversight throughout the AI journey.

Future Trends of AI in FMCG

Predictions for the Next Decade

Over the next decade, AI will become an essential strategic layer in FMCG operations, far beyond simple automation. It will power next-gen personalization in product design, marketing, and customer service by delivering real-time insights from billions of data points. Predictive AI will not just react to consumer behavior but forecast demand shifts, supply chain disruptions, and market trends before they happen.

Over the next decade, AI will become an essential strategic layer in FMCG operations, far beyond simple automation. It will power next-gen personalization in product design, marketing, and customer service by delivering real-time insights from billions of data points. Predictive AI will not just react to consumer behavior but forecast demand shifts, supply chain disruptions, and market trends before they happen.

Smaller FMCG brands will also begin to access advanced AI tools as cloud platforms democratize these capabilities. Innovations like generative packaging, voice-of-customer sentiment analysis, and AI-powered product R&D will become mainstream. Simultaneously, stricter regulations around AI ethics, transparency, and sustainability will push companies to deploy responsible and accountable AI at every level.

How Businesses Can Stay Ahead of the Curve

To stay competitive, FMCG businesses must invest in AI literacy and build agile, data-driven cultures. Training staff on how to use AI tools and interpret outputs will be as vital as the technology itself. Cross-functional collaboration between marketing, logistics, R&D, and IT will be crucial for seamless AI adoption.

Leading companies will treat AI as an evolving capability, not a one-time investment. This means running frequent pilot programs, analyzing outcomes, and adapting tools to meet changing needs. Those who blend human creativity with machine intelligence will not only future-proof their operations but redefine what’s possible in FMCG.

Conclusion

Key Takeaways on AI Use Cases in FMCG

AI is redefining how FMCG companies innovate, operate, and compete, from personalized marketing and intelligent shelf tracking to predictive supply chain optimization. The technology not only boosts efficiency but also enhances sustainability and agility, allowing businesses to meet shifting consumer demands in real time. As shown through industry examples, AI delivers measurable ROI by cutting costs, improving speed, and enabling smarter decisions across the value chain.

However, unlocking these benefits requires strategic planning and execution. A solid data foundation, the right tools, and a skilled team are crucial to sustainable AI success. Businesses that invest early in responsible, well-integrated AI systems will be best positioned to thrive in the rapidly evolving FMCG landscape.

Moving Forward: A Path to Progress

If you’re leading an FMCG company and aiming to reduce operational waste, accelerate decision-making, or deliver hyper-personalized experiences at scale, now is the time to explore AI. Start with a focused pilot in one key area like demand forecasting or digital shelf management and use it to build confidence and proof of ROI. Don’t wait for competitors to outpace you with smarter, faster, more adaptive systems.

At SmartDev, we help FMCG businesses harness AI to optimize everything from factory floor efficiency to customer engagement strategies. Whether you’re beginning your AI journey or ready to scale, we offer tailored solutions that align with your specific goals and infrastructure.

Let us help you turn AI from a buzzword into your most powerful growth driver!

—

References:

- AI-Driven Operations Forecasting in Data-Light Environments | McKinsey

- AI in Modern Supply Chain Management | Deloitte

- Generative AI in FMCG Market | Market.us

- Procter & Gamble Uses Azure AI to Enhance Operations | Microsoft

- How AI Is Transforming Unilever Ice Cream’s End-to-End Supply Chain | Unilever

- Artificial Intelligence at Nestlé | Emerj

- Coca-Cola Enterprises Optimizes Vehicle Routes for Efficient Product Delivery | ResearchGate

- Real-Time Inventory Analysis Using Jetson Nano with Object Detection and Analysis | ResearchGate

- Danone’s Digital Transformation Story | Danone

- P&G Taps AI and Automation for Faster, Smarter Operations | Consumer Goods Technology

1. Enhanced Demand Forecasting and Inventory Optimization

1. Enhanced Demand Forecasting and Inventory Optimization Fragmented Cold Chain and Perishable Product Data

Fragmented Cold Chain and Perishable Product Data 1. AI‑Powered Demand Forecasting

1. AI‑Powered Demand Forecasting Examples of AI in FMCG

Examples of AI in FMCG Step 1. Assessing Readiness for AI Adoption

Step 1. Assessing Readiness for AI Adoption