Quick Introduction

The food industry is facing mounting pressure—from escalating food waste and supply chain complexity to shifting consumer preferences and tight margins. AI use cases in food industry are emerging as powerful levers—enhancing quality control, optimizing logistics, and driving innovation from production to delivery.

This guide details how AI is applied across the food value chain to generate measurable impact and competitive advantage.

What is AI and Why Does It Matter in the Food Industry?

Definition of AI and Its Core Technologies

Definition of AI and Its Core Technologies

Artificial Intelligence (AI) refers to computer systems designed to perform tasks that typically require human intelligence—such as pattern recognition, decision-making, and learning from experience. These systems often rely on core technologies like machine learning (ML), natural language processing (NLP), and computer vision.

In the food industry, AI enables smarter production, logistics, and consumer engagement. Whether it’s using computer vision for quality control on assembly lines or applying ML for predictive maintenance in food processing equipment, AI improves accuracy, scalability, and responsiveness across the value chain.

Want to explore how AI can transform your sector? Discover real-world strategies for deploying smart technologies in airline systems. Visit How to Integrate AI into Your Business in 2025 to get started today and unlock the full potential of AI for your business!

The Growing Role of AI in Transforming Food Industry

AI-powered precision agriculture is helping farmers optimize planting schedules, irrigation, and pesticide use—reducing waste and increasing yields. Satellite imagery and AI-based sensors can detect crop stress or disease early, enabling timely interventions and protecting food security.

In manufacturing and processing, AI models monitor temperature, hygiene compliance, and shelf life to improve food safety. Robotics integrated with computer vision are now automating packaging and grading tasks, reducing labor dependency and minimizing human error.

Consumer-facing innovations are also emerging. AI is personalizing meal recommendations and nutritional guidance based on dietary restrictions or health goals. Food brands use AI to analyze trends from social media, reviews, and purchase data to develop products that meet evolving tastes.

Key Statistics or Trends in AI Adoption

AI is gaining momentum across the global food value chain. According to Precedence Research, the global AI in food and beverages market is projected to reach $48.9 billion by 2032, growing at a CAGR of 45.4% from 2023 to 2032.

One of the biggest adoption drivers is the demand for smarter supply chain forecasting. A McKinsey report noted that AI-driven demand forecasting can improve service levels by up to 65% while reducing inventory costs by 20–30%—a game-changer in an industry with tight margins and perishable goods.

Food safety is another focal point. According to the FDA, about 48 million Americans get sick from foodborne illnesses each year. AI-powered inspection and anomaly detection systems help prevent such incidents, boosting compliance and consumer trust.

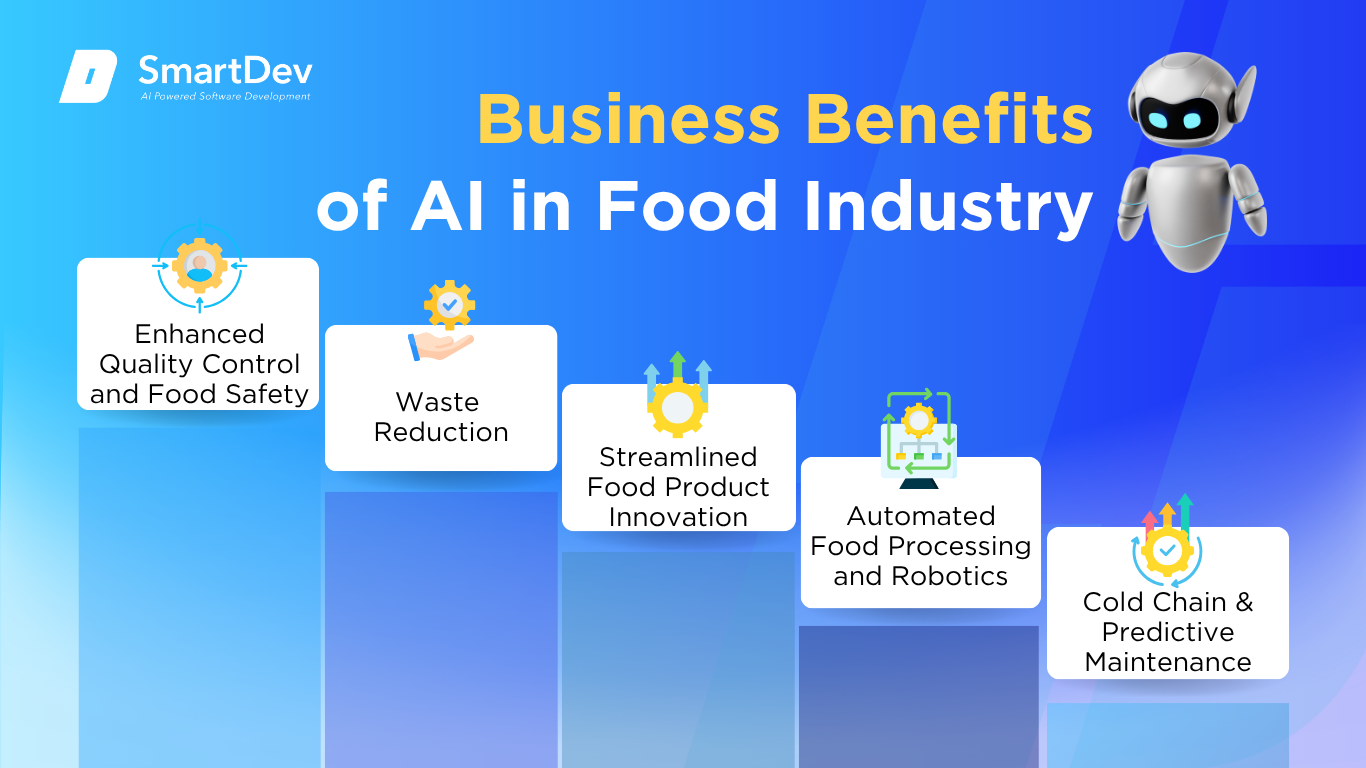

Business Benefits of AI in the Food Industry

AI is generating tangible returns by addressing costly, persistent challenges such as waste, quality inconsistency, and inefficient logistics. Let’s look at five core benefits tied to real‑world problems.

1. Enhanced Quality Control and Food Safety

1. Enhanced Quality Control and Food Safety

AI‑powered computer vision systems inspect every product on the line—detecting defects, contamination, or packaging errors in real time. This reduces food safety risks and recall potential. For example, companies like Coca‑Cola and other beverage producers use AI inspection tools to flag anomalies early, improving defect detection and minimizing waste.

The result is fewer product errors, stronger regulatory compliance, and better consumer trust. You get higher consistency without relying solely on manual inspectors, lowering recall costs and enhancing reputation across channels.

2. Waste Reduction Through Predictive Demand and Inventory

Food spoilage and overstock cost billions. AI systems analyze historical sales, weather patterns, and external trends to predict demand accurately. For instance, Juici Patties boosted U.S. sales by 12% while reducing stock‑outs by applying AI‑based forecasting tools in fast food supply chain operations.

These insights help you align orders with real-time demand, significantly cutting spoilage, markdowns, and inventory holding costs. As a result, your supply chain becomes both leaner and more responsive.

3. Streamlined Food Product Innovation

Recipe development often involves months of trial and consumer testing. AI accelerates this by simulating ingredient blends and predicting consumer acceptance. Mondelez’s use of an AI platform reduced product development timelines by 4–5 ×, resulting in a 5.4% sales lift and faster delivery of innovations like gluten‑free Golden Oreo.

You’ll launch new food products faster, reduce R&D cost, and align more closely with evolving consumer taste trends—fueling growth without traditional trial‑and‑error bottlenecks.

4. Automated Food Processing and Robotics

On the production floor, robotics integrated with AI and computer vision streamline tasks like sorting, packaging, and inspection. U.S. companies such as FarmWise deploy robotic weeders using ML to precisely remove weeds, reducing chemical use and labor costs in vegetable fields.

In manufacturing plants, AI‑guided robots improve throughput, reduce manual handling, and maintain hygiene standards. These systems enable efficient high-volume processing while adhering to stringent safety protocols.

5. Efficient Cold Chain and Predictive Maintenance

Temperature-sensitive products rely on reliable cold chain infrastructure. AI monitors sensors and equipment data to detect anomalies and predict failure before breakdowns occur. Companies like Unilever in Sweden improved forecast accuracy by 10%, enhancing frozen inventory control and reducing waste through AI systems.

This predictive capability prevents spoilage, cuts downtime, and ensures continuity in distribution—critical in frozen, dairy, or perishable categories.

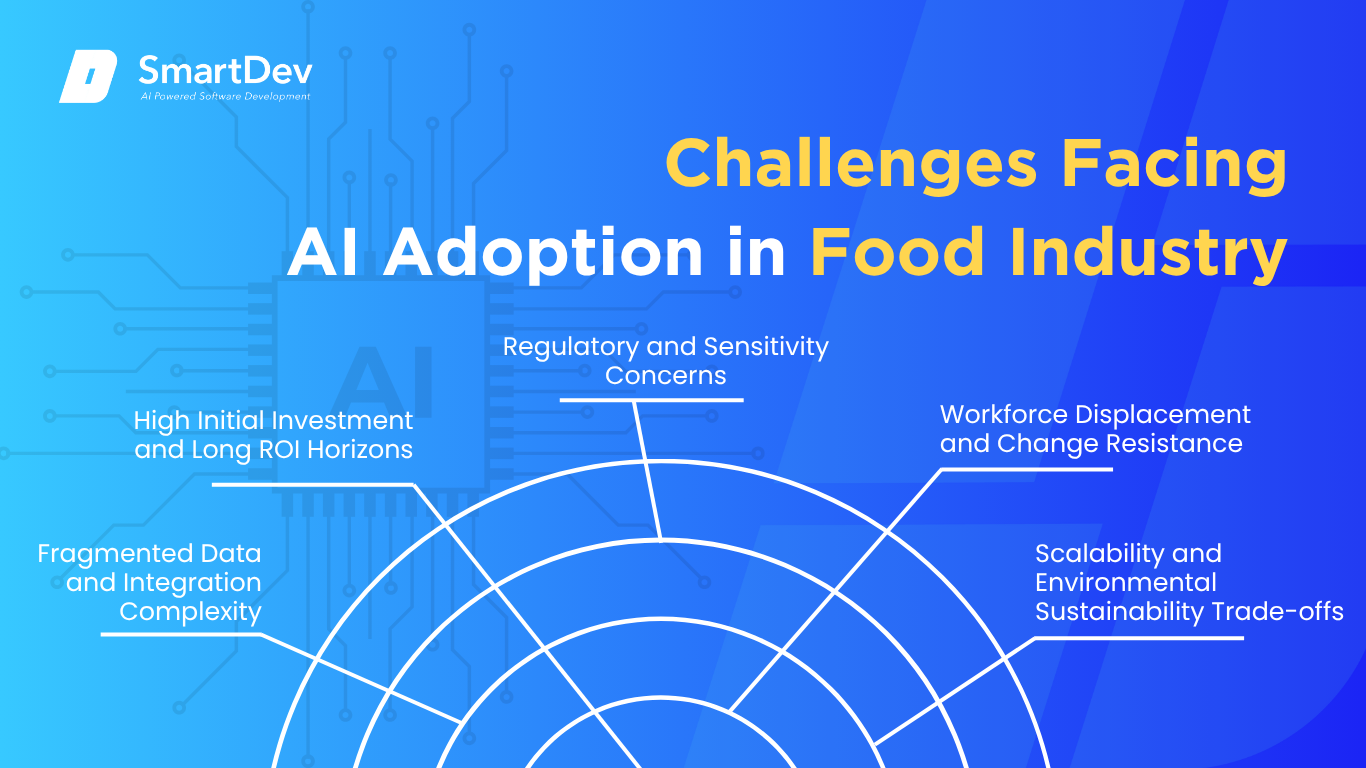

Challenges Facing AI Adoption in the Food Industry

Implementing AI-powered systems isn’t without obstacles. Here are five specific challenges that could limit impact if not managed proactively.

1. Fragmented Data and Integration Complexity

1. Fragmented Data and Integration Complexity

Food systems generate data across farms, processing lines, logistics, and retail—often in silos. Inconsistent formats, manual entry errors, and legacy systems make it hard for AI models to ingest high-quality data. Without integration and cleaning, predictive analytics or vision systems fail to perform reliably.

Bridging these silos requires standardization, APIs, and robust pipelines. Establishing data governance across agribusiness, manufacturing, and logistics teams is essential—yet often neglected until late in projects.

Siloed systems and scattered data can cripple decision-making and slow growth. Discover how AI is helping organizations unify, clean, and unlock value from their data faster and smarter. Explore the full article to see how AI transforms data chaos into clarity.

2. High Initial Investment and Long ROI Horizons

Deploying AI in manufacturing or robotics often means expensive hardware, sensor arrays, and integration costs. Early adopters face uncertain ROI timelines—particularly for SMEs. That can deter investment until case studies prove value.

To overcome this, companies should pilot narrowly—e.g., vision inspection on one SKU—then measure outcomes before scaling. Starting with cost‑sensitive areas (e.g. waste reduction) enables clearer ROI justification.

3. Regulatory and Sensitivity Concerns

AI in food safety must satisfy stringent regulations, especially for allergens, contamination, and traceability. Models must be auditable, explainable, and validated under food compliance standards. Vision systems must capture near-perfect accuracy; false negatives could risk public health.

You must implement human-in-the-loop verification and oversight. Partnerships with audit bodies and validation protocols minimize risks and foster trust in AI‑based decisions.

For those navigating these complex waters, a business-oriented guide to responsible AI and ethics offers practical insights on deploying AI responsibly and transparently, especially when public trust is at stake.

4. Workforce Displacement and Change Resistance

Automation can raise concerns about job loss in processing or quality control roles. Workers may resist AI if it seems opaque or threatens livelihoods. Without clear transition planning, adoption stalls and ROI suffers.

Address this by reskilling staff, positioning AI as an assistant rather than a replacement. Human‑AI collaboration training helps operators trust validation flags, exceptions handling, and oversight functions.

5. Scalability and Environmental Sustainability Trade-offs

High-throughput AI systems require powerful compute, sensors, and electricity—raising sustainability questions in resource-sensitive operations. Expanding pilots across global facilities can strain standards and cloud infrastructure. Additionally, infrastructure may vary by region, making uniform deployment difficult.

Balancing environmental impact requires edge computing, energy-efficient hardware, and optimized models. You’ll need to design AI architecture that scales responsibly across facilities and geographies.

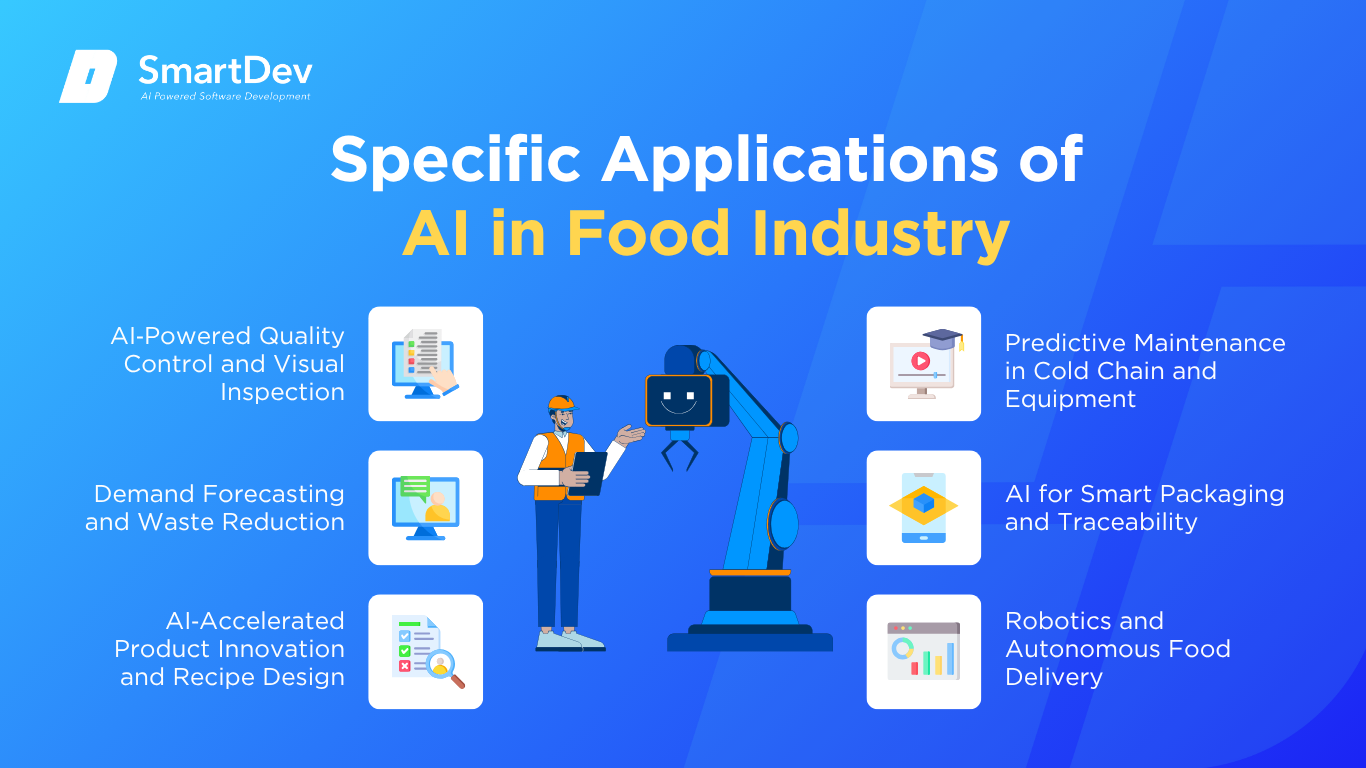

Specific Applications of AI in the Food Industry

Use case 1: AI‑Powered Quality Control and Visual Inspection

Use case 1: AI‑Powered Quality Control and Visual Inspection

AI in food industry increasingly tackles visual defects that manual inspection often misses—crucial for maintaining safety and reducing waste. Computer vision systems can detect foreign objects, discoloration, bruising, or packaging errors at line speed. These systems use deep learning models trained on thousands of labeled images to recognize anomalies and flag non‑conforming products in real time.

Working with convolutional neural networks (CNNs), AI models analyze high-resolution video or still images from conveyor belts to distinguish acceptable items from rejects. Feeding continuous data into the system enables real‑time defect detection, integrating with sorting conveyors and alert mechanisms. Vision systems help streamline quality workflows and reduce dependence on slower human inspection.

The operational value is clear: fewer recalls, improved consistency, and lower waste. For safety‑critical categories like dairy, meat, or produce, this translates directly to cost savings and regulatory compliance. Ethical considerations include ensuring diverse training data to avoid bias toward specific product variations or lighting conditions.

In one real‑world example, a large beverage and snack producer implemented vision AI on its bottling lines to catch label misalignment and liquid level discrepancies. They used a third‑party AI vision vendor integrated with existing sorting systems. The result: a 30% reduction in defects and a 20% drop in manual rework time.

Use case 2: Demand Forecasting and Waste Reduction

Over‑ordering and poor demand alignment frequently lead to spoilage and margin erosion in food retail and quick‑service operations. AI demand forecasting analyzes historical point‑of‑sale data, external factors like weather and holidays, and consumer trends to generate precise daily and SKU‑level forecasts. This approach minimizes overstock and aligns procurement with real-time demand signals.

These systems leverage time‑series forecasting, machine learning algorithms, and external data ingestion (e.g. weather, events, promotions). Algorithms are trained continuously and integrate with inventory systems to automate reorder alerts and optimize stock levels. When predictive models flag potential surpluses, inventory managers adjust procurement upstream.

By tightening alignment between demand and inventory, companies reduce waste, lower carrying costs, and improve sales uptime. Strategic operational value includes increased inventory turnover and leaner supply chain operations. Ethical considerations include data privacy when ingesting customer data and maintaining transparency in algorithmic decisions.

A case in point: Juici Patties, a fast‑casual chain, implemented AI forecasting for its distribution center logistics using POS and weather data. Partnering with an AI vendor, they prevented stockouts and improved inventory turns. As a result, they reported a consistent increase in daily sales and higher customer satisfaction metrics.

Use case 3: AI‑Accelerated Product Innovation and Recipe Design

Traditional food R&D often involves lengthy experimentation, sensory testing, and high costs. AI platforms now simulate ingredient combinations, optimize for nutrition, cost, supply, and taste preference, enabling rapid concept iteration. This accelerates recipe development while reducing lab testing and consumer panels.

These tools use generative machine learning, optimization algorithms, and multi‑objective modeling to generate candidate recipes from ingredient databases. They consider environmental impact, allergen constraints, and sensory characteristics. The AI system then ranks options, and human sensory teams finalize selected versions.

Strategically, accelerated innovation cycles increase speed to market, cost efficiency, and alignment with consumer trends. Ethical and technical considerations involve transparency in ingredient sourcing, label compliance, and cultural appropriateness. Models must ensure allergen safety and regulatory validation.

Mondelez International worked with Fourkind to apply recipe‑generating AI across over 70 product projects, including a Gluten Free Golden Oreo. The system accelerated development time by 4–5×, and the new products lifted sales by ~5.4% in the quarter after launch.

Use case 4: Predictive Maintenance in Cold Chain and Equipment

Cold chain logistics requires precise temperature control to prevent spoilage, often across multiple facilities. AI monitors sensors from refrigeration units, forklifts, and storage environments to predict equipment failures or temperature excursions. This helps to proactively maintain systems and protect inventory integrity.

Using anomaly detection, digital twins, and predictive modeling, the system learns normal operating patterns and flags deviations. Models integrate with IoT sensor networks and facility management systems to trigger alerts or maintenance workflows. When thresholds are breached, control systems can self-adjust or escalate to maintenance teams.

Operational gains include fewer breakdowns, less spoilage, and better labor efficiency in refrigerated storage or fleet logistics. Risk mitigation through AI reduces financial loss and supports regulatory compliance. Data security and connectivity must be managed across distributed facilities and third‑party suppliers.

For example, Unilever in Sweden used AI in its cold chain logistics to correlate weather with inventory demands, improving forecast accuracy by ~10% and boosting U.S. sales by 12% via reduced downtime and spoilage.

Use case 5: AI for Smart Packaging and Traceability

Ensuring freshness, traceability, and shelf life across multi‑tier distribution is a rising consumer and regulatory expectation. Intelligent packaging embeds sensor data and real‑time analytics to monitor temperature, humidity, and time‑in‑transit. AI processes this data to validate product integrity and trigger alerts when thresholds are exceeded.

This solution combines IoT-enabled tags, decentralized sensors, and cloud‑based analytics to continuously monitor product conditions. Machine learning identifies risk patterns—such as early warming during transit—and propagates alerts back through the supply chain. Data dashboards feed back into operations and quality verification processes.

The strategic value lies in elevated transparency, reduced spoilage, and improved brand trust. Recall response time decreases and traceability improves. Key ethical considerations include consumer privacy, sensor-infrastructure costs, and data ownership across the supply chain.

Academic studies highlight AI‑embedded packaging improving safety and shelf‑life tracking in fresh produce and cold chain environments.

Use case 6: Robotics and Autonomous Food Delivery

Delivering meals consistently at scale involves operational and labor challenges—especially in fast food and local delivery. AI‑driven autonomous robots and drones now navigate sidewalks and airspace to deliver meals with reduced human contact and increased precision. They optimize routes, avoid obstacles, and interface directly with order systems.

These delivery systems incorporate computer vision, sensor fusion (e.g. LIDAR, GPS), and path‑planning algorithms to chart safe routes and handle deliveries. AI agents coordinate pickups and drop‑offs, communicate with recipients, and manage battery or payload logistics. Their systems integrate with restaurant order platforms and logistical workflows.

The value is faster delivery, lower labor dependence, and consistent service quality. Delivery bots reduce human error, minimize delays, and support scalability in urban areas. Considerations include regulation, sidewalk accessibility, privacy, and initial infrastructure investment.

Coco Robotics and Serve Robotics are already delivering food autonomously in U.S. cities, while drone services like Zipline and Wing conduct aerial delivery tests—collectively addressing food delivery demands with better speed and precision.

Need Expert Help Turning Ideas Into Scalable Products?

Partner with SmartDev to accelerate your software development journey — from MVPs to enterprise systems.

Book a free consultation with our tech experts today.

Let’s Build TogetherExamples of AI in the Food Industry

These specific use cases underscore operational impact. The following case studies showcase measurable outcomes from pioneering food industry AI initiatives.

Real-World Case Studies

Mondelez International: Recipe Innovation at Scale

Mondelez International: Recipe Innovation at Scale

Mondelez collaborated with Fourkind to deploy AI for new snack formulation and product variants, incorporating cost, nutrition, taste, and sustainability into optimized recipe generation. The AI system supported over 70 projects, including a gluten‑free Oreo variant. After deployment, R&D timelines accelerated by 4–5×, and new product launches drove ~5.4% incremental sales growth in representative quarters.

Meanwhile, the company maintained human sensory validation to preserve brand consistency. This hybrid approach reduced lab testing cycles and eliminated many expensive formulation iterations. As a result, product innovation moved from artisanal timelines to data‑driven agility.

Juici Patties / Fast‑Food Chains: Demand Forecasting & Supply Efficiency

Juici Patties implemented AI demand forecasting by blending POS, weather, and local event data to manage inventory for its distribution centers. This reduced stockouts and improved daily sales consistency. The chain also optimized opening hours and delivery logistics based on insights from the AI system, boosting operational efficiency across multiple locations.

Major fast-food chains like McDonald’s, Domino’s, Starbucks, and Yum Brands adopted similar platforms using partnerships with Google Cloud, Microsoft, Nvidia, and IBM. Systems are now handling inventory orders, labor optimization, and menu personalization. Chains reported meaningful reductions in waste and improvements in digital same-store sales, such as a 15% increase reported by Yum Brands in 2024.

Fresho (Australia): Wholesale Food Order Optimization

Fresho built an AI-powered ordering and forecasting system for fresh-produce wholesalers, structuring inbound orders and recommending optimal quantities. Processing over 30 million orders to date, the platform significantly reduced ordering errors and typical wastage rates. Fresh food suppliers using the system experienced measurable reductions in spoilage—driving more accurate purchases and lowering inventory write-offs in the 30–40% wastage range common in fresh food distribution.

These results underscore the strategic value of AI in fresh food supply chain transparency and waste reduction.

These examples reflect the value of working with technology partners who understand both the technical and policy implications. If you’re considering a similar digital transformation, don’t hesitate to connect with AI implementation experts to explore what’s possible in your context.

Innovative AI Solutions

Bridging past use cases and future innovation, emerging AI solutions are poised to reshape how food companies operate at scale. The trend toward more autonomous, explainable, and sustainable AI is accelerating across R&D, operations, and delivery.

Generative AI continues to redefine recipe and product development by simulating ingredient combinations and consumer preferences for rapid iteration. Meanwhile, computer vision and sensor fusion are advancing inspection, traceability, and delivery systems that can act autonomously—and yet remain auditable and transparent.

AI is also powering smart packaging solutions, digital twins for cold chain modeling, and autonomous delivery. These innovations not only drive efficiency and quality but also support sustainability by reducing wastage, lowering carbon footprint, and enhancing transparency across the food value chain.

AI‑Driven Innovations Transforming Food Industry

Emerging Technologies in AI for Food Industry

You’ve probably noticed how AI technologies are reshaping the food sector—especially through generative AI and computer vision applications. Generative AI can now assist with content creation and creative recipe formulation by simulating flavor combinations and predicting consumer acceptance. Companies like Mondelez and Fourkind have used these models to prototype new snacks rapidly, reducing R&D timelines by 4–5× and achieving measurable sales increases in weeks rather than months (wsj.com).

Meanwhile, computer vision systems have matured significantly, enabling live visual inspection of food items and packaging. These AI-driven inspection lines detect defects, mislabeling, or contamination using convolutional neural networks, reducing defect rates by up to 30% and lowering manual rework significantly. Implemented at scale in beverage and produce operations, these systems elevate product consistency and consumer safety without slowing throughput.

AI’s Role in Sustainability Efforts

Sustainability isn’t a buzzword—it’s a strategic necessity, and AI plays a pivotal role. Predictive analytics help you forecast demand more accurately, cutting spoilage and food waste by aligning production or procurement levels with expected consumption. OrderGrid and ThroughPut AI report grocery operations reducing waste by up to 40% and stockouts by 30% through data-driven forecasting (turn0search5, turn0search17).

Smart systems also minimize energy consumption in cold-chain logistics by dynamically allocating refrigeration based on load forecasts and optimizing pallet placement. Companies like Lineage Logistics and Americold use AI-driven warehouse optimization and digital twins to minimize temperature deviations and worker inefficiencies in sub-zero environments. Unilever reports a 10% forecast accuracy uptick in Sweden and a 12% U.S. sales improvement in ice cream lines through AI‑enabled climate-demand alignment.

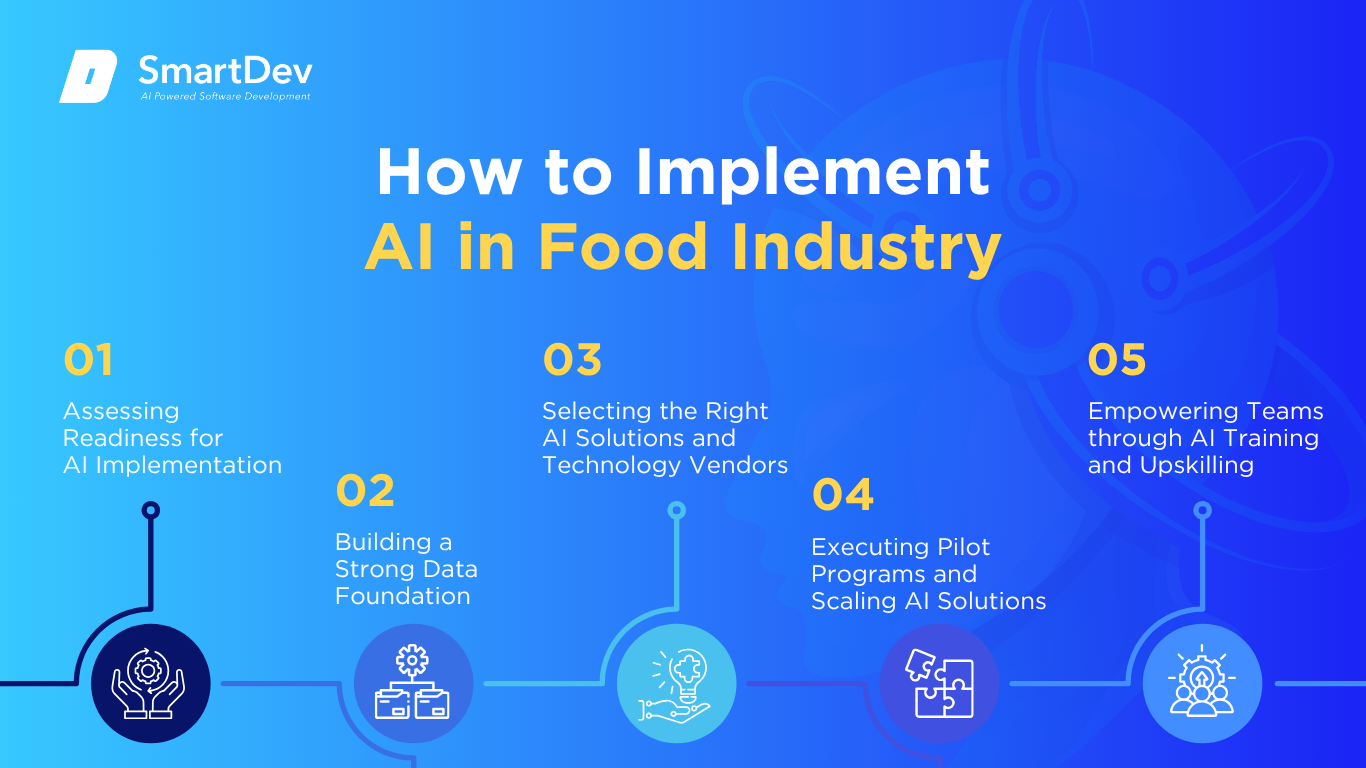

How to Implement AI in Food Industry

Step 1: Assessing Readiness for AI Adoption

Before investing in technologies, assess which parts of your food operation are most ripe for AI—like forecasting, inspection, or recipe innovation. Identify workflows with repetitive tasks or high waste rates, such as manual quality checks or forecasting errors, where automation can deliver measurable impact. Map use cases to business problems—such as spoilage, labor bottlenecks, or innovation speed—to prioritize pilot projects.

You’ll also need to evaluate your existing systems: are your ERP, POS, and DMS platforms flexible enough to integrate AI? Legacy systems often isolate key data in silos, undermining model accuracy. A readiness assessment should cover data quality, stakeholder alignment, and operational goals—ensuring project scope is realistic, ROI-focused, and scalable.

Step 2: Building a Strong Data Foundation

High-performing AI relies on clean, integrated data from across the value chain—from raw material sourcing and batch records to sales and spoilage data across channels. Establish governance roles to standardize file formats, metadata, and cleaning protocols; this minimizes bias and improves model accuracy. Consistent data labeling across suppliers and SKUs lets ML models generalize instead of overfitting to narrow conditions.

Secure data pipelines are equally essential. Use cloud services or encrypted storage to centralize data ingestion while maintaining access control. Once data flows are in place, conduct validation tests on sample datasets to ensure models won’t falter on edge cases like seasonal SKU surges or regional demand anomalies.

Step 3: Choosing the Right Tools and Vendors

You have many vendor choices: from enterprise-grade platforms such as C3 AI, Google Cloud’s Document AI (repurposed for recipe generation and forecasting), and Microsoft Syntex to niche providers like Fourkind, OrderGrid, and ThroughPut AI. Evaluate providers on integration capabilities, domain expertise, compliance support, explainability, and scalability.

For example, C3 AI worked with a global food manufacturer to unify data from 18 sources and implement demand forecasting and schedule optimization, achieving an 8% lift in forecast accuracy and nearly $30M in gross margin gains over 16 weeks (turn0search1). Seek vendors with track records in food specifically—so you get faster time to value and industry-relevant outcomes.

Step 4: Pilot Testing and Scaling Up

Start with small, high-impact pilots—such as applying vision AI on one production line or deploying forecasting for a single product category. Use these pilots to measure accuracy improvements, waste reduction, or cycle time gains. Introduce human-in-the-loop feedback so that the models learn from exceptions and improve their decision-making over time.

Once your pilot meets performance thresholds, gradually scale across SKUs, facilities, or regions. Maintain centralized oversight of exceptions, KPI dashboards, and audit logs. As scale grows, ensure governance evolves, feedback loops are continuous, and models are retrained periodically to avoid drift.

Step 5: Training Teams for Successful Implementation

Even the most advanced AI requires humans who understand its limitations and can interpret outcomes. Train your production and operations teams in how to review alerts, flag exceptions, and validate AI decisions—particularly around quality control or forecasting. Engage “superusers” who champion adoption, mentor peers, and liaise with vendors to refine systems.

Clear communication from leadership is vital too. Show your teams real benefits—such as reduced spoilage or faster inspection—and connect these gains to organizational goals. When people understand the “why” behind AI, adoption improves significantly, and the technology transitions from threat to valuable collaborator.

Whether you’re exploring your first pilot or scaling an enterprise-wide solution, our team is here to help. Get in touch with SmartDev and let’s turn your supply chain challenges into opportunities.

Measuring the ROI of AI in Food Industry

Key Metrics to Track Success

You need to measure success beyond basic model accuracy; focus on hard business metrics such as waste reduction, labor hours saved, throughput improvements, and revenue uplift. Track processing time savings—like manual inspection time dropping from minutes to seconds—or inventory carrying cost improvements driven by better forecasting.

Also, monitor user adoption rates, exception resolution times, and compliance incidents. For instance, improvement in fill rate or on-time deliveries reflect system reliability in forecasting and cold chain coordination. Combing qualitative feedback (staff satisfaction, fewer manual interventions) with quantitative results gives you a balanced ROI scorecard that resonates with executive stakeholders.

Case Studies Demonstrating ROI

Axelliant’s implementation with a global food manufacturer improved demand forecasting accuracy and streamlined production scheduling, delivering $30M in additional gross margin across production sites and reducing scheduling time by 96% (turn0search1). The company unified over 72M rows of data and optimized 8 production lines in just 16 weeks.

Meanwhile, ThroughPut AI helped Church Brothers Farms improve short-term forecast accuracy by up to 40%, minimizing overstock and aligning supply with customer demand. This translated into improved logistics efficiency and more competitive margins across perishable goods operations (turn0search5).

Zest’s AI tool trial with Nestlé in the UK resulted in an 87% reduction in edible food waste, potentially saving 700 tonnes of surplus and reducing CO₂ emissions by 1,400 tonnes—translating to approximately £14M in cost savings during just a two-week test period.

Understanding ROI is possibly a challenge to many businesses and institutions as different in background, cost. So, if you need to dig deep about this problem, you can read AI Return on Investment (ROI): Unlocking the True Value of Artificial Intelligence for Your Business

Common Pitfalls and How to Avoid Them

A frequent pitfall is rushing into AI without a clean data foundation; poor data leads to inaccurate forecasts or misclassifications that erode trust quickly. Avoid this by ensuring rigorous data cleaning, governance workflows, and pilot validation before scaling.

Another challenge is ignoring user adoption. If end-users distrust AI outputs—especially in critical areas like quality inspection or payroll—they may circumvent the system. Solicit feedback, train teams, and maintain human-in-the-loop oversight. Additionally, beware over-reliance on AI in regulatory or safety contexts—always align with compliance frameworks and validate decisions via expert review.

Future Trends of AI in Food Industry

Predictions for the Next Decade

Predictions for the Next Decade

Looking ahead, AI will evolve into sophisticated assistants—virtual agents that understand commands like “show me all recalled batches of dairy items this quarter” and surface compliant documents or risk screens. Explainable AI (XAI) will become essential regulatory infrastructure, especially in food safety contexts where auditability and transparency are critical. Digital twins of entire food supply chains—from farm sensors to cold storage to retail shelves—will enable simulation-based optimization, supporting more resilient operations.

AI-driven packaging that actively communicates freshness and expiry via blockchain-backed traceability will further boost consumer confidence and reduce waste. Generative AI will move into marketing and operations—auto-generating labels, content, and tailored production suggestions based on seasonal demand and consumer trends. Autonomous delivery robots, drones, and microbiome-enhanced personalized nutrition are also poised to converge with AI to make food delivery highly individualized and scientifically grounded.

How Businesses Can Stay Ahead of the Curve

To maintain leadership, begin by investing in pilot projects with clear ROI paths—such as demand forecasting or vision inspection—and gradually layer in AI innovations like generative recipe modeling or smart packaging. Build cross-functional teams combining supply chain, IT, operations, and compliance to map out long-term strategies and identify integration opportunities early.

Stay plugged into vendor innovation—XAI, hybrid retrieval architectures, and GenAI + digital twin platforms can offer new capabilities. Engage with food industry consortiums and regulatory bodies to influence best practices and maintain alignment with evolving safety and traceability standards. By proactively aligning AI initiatives with ESG goals and consumer transparency expectations, your organization can scale responsibly and lead in a competitive, sustainability-driven landscape.

Conclusion

Summary of Key Takeaways on AI Use Cases in Food Industry

We’ve explored powerful AI use cases in food industry—from quality inspection powered by computer vision and predictive demand forecasting to recipe accelerated innovation, cold-chain predictive analytics, smart packaging, and autonomous delivery systems. Each application drives real business value in waste reduction, operational efficiency, sales growth, and compliance readiness through measurable interventions.

We’ve also shown how to implement AI successfully: assess readiness, build clean data pipelines, pilot wisely, choose domain-experienced vendors, and focus on user training. Robust measurement of ROI via actual business KPIs ensures you build the case for scaling while avoiding common pitfalls like data bias, low trust, or overreliance.

Moving Forward: A Path to Progress for Businesses Considering AI Adoption

If you’re ready to transform operations and drive real ROI from AI in the food industry, begin with a high-impact pilot in forecasting or quality inspection. Partner with vendors who understand your domain and can embed explainable, secure, and scalable models.

Combine technology with human oversight and governance to build trust and maximize results. Let us help you design a strategic roadmap—from data foundation to pilot, scale, and innovation—enabling you to lead with smarter, more sustainable food operations.

References

- The Latest AI Trends Transforming The Food Industry

- How AI is Crafting the Future of the Food Industry

- Top 10: Uses of AI in the Food Industry

- Powering the food industry with AI

- AI in food industry automation: applications and challenges

- AI in the Food Industry: Case Studies, Challenges & Future Trends

Definition of AI and Its Core Technologies

Definition of AI and Its Core Technologies 1. Enhanced Quality Control and Food Safety

1. Enhanced Quality Control and Food Safety 1. Fragmented Data and Integration Complexity

1. Fragmented Data and Integration Complexity Use case 1: AI‑Powered Quality Control and Visual Inspection

Use case 1: AI‑Powered Quality Control and Visual Inspection Mondelez International: Recipe Innovation at Scale

Mondelez International: Recipe Innovation at Scale

Predictions for the Next Decade

Predictions for the Next Decade