Manufacturing executives evaluating computer vision cost manufacturing deployments face a critical information gap: most vendors provide vague estimates while implementation realities reveal expenses 40-60% higher than initial quotes. This comprehensive analysis delivers transparent CV system pricing based on 2025 market data, real implementation case studies from Jidoka Tech, and total cost of ownership frameworks that manufacturing leaders need for accurate budget planning.

The global industrial machine vision market reached $15.9 billion in 2025, growing at 12.3% annually toward $24.6 billion by 2030 according to Congruence Market Insights. Yet 68% of manufacturers report budget overruns on their first computer vision project, primarily due to underestimated integration complexity and ongoing operational expenses. Understanding the complete manufacturing AI budget requires examining five distinct cost categories: hardware, software development, implementation, hidden operational expenses, and opportunity costs.

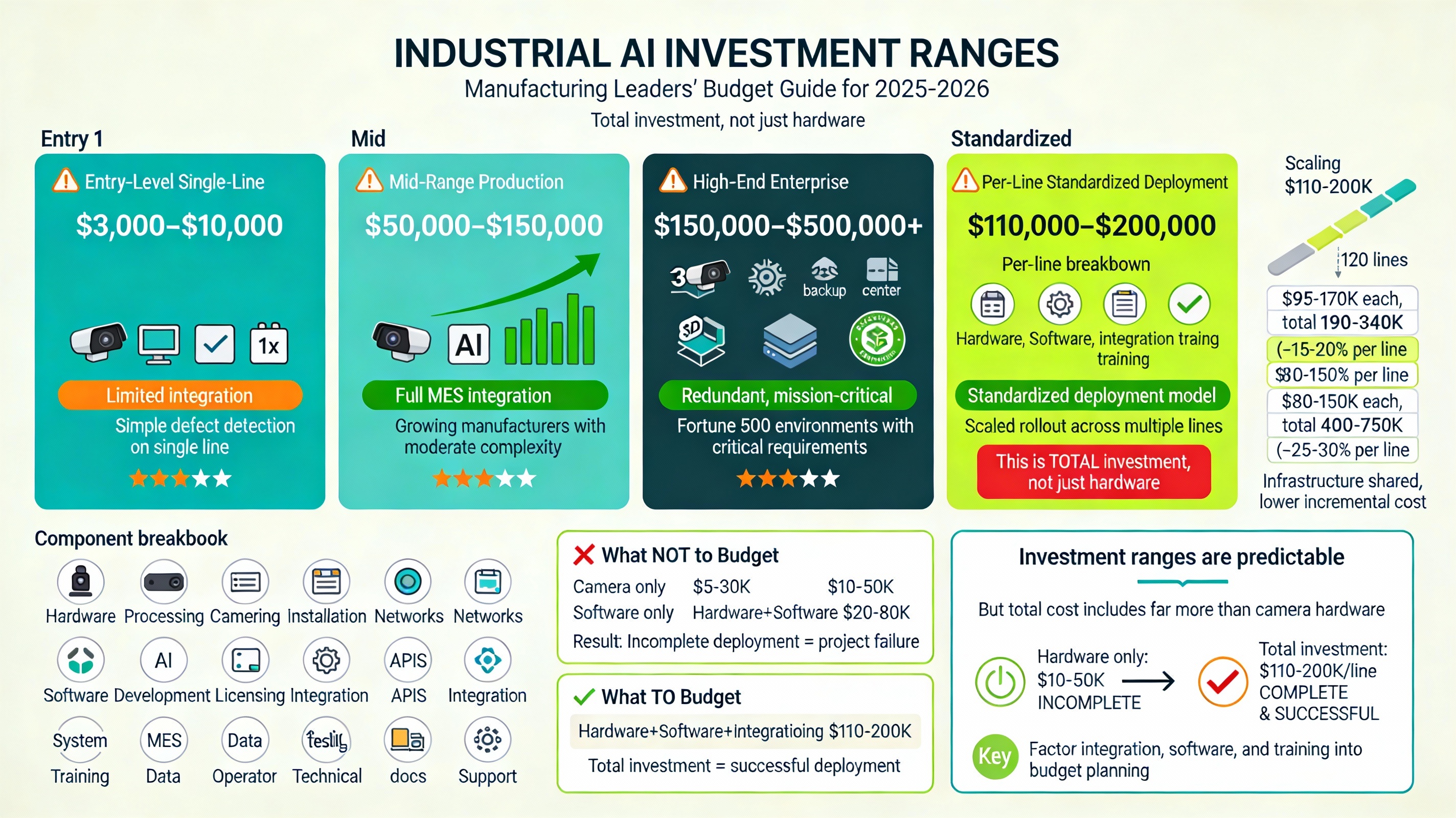

Executive Summary: Realistic Investment Ranges

Before diving into detailed cost breakdowns, manufacturing leaders need clear budget expectations. Based on 2025 deployment data across 200+ production facilities, industrial AI pricing follows predictable patterns based on system complexity and scale.

Entry-Level Single-Line Systems: $3,000-$10,000

-

Basic 2D cameras with standard software

-

Limited integration capabilities

-

Suitable for simple defect detection on single production lines

Mid-Range Production Systems: $50,000-$150,000

-

Professional-grade cameras and custom AI models

-

Full MES integration and multi-defect detection

-

Typical for growing manufacturers with moderate complexity

High-End Enterprise Deployments: $150,000-$500,000+

-

Multi-camera 3D arrays with advanced analytics

-

Redundant systems and centralized management

-

Fortune 500 manufacturing environments with critical quality requirements

Per-Line Implementation Cost: $110,000-$200,000 when accounting for hardware, software, integration, and training across a standardized deployment.

These figures represent total investment, not just hardware acquisition—a distinction that separates successful implementations from budget disasters.

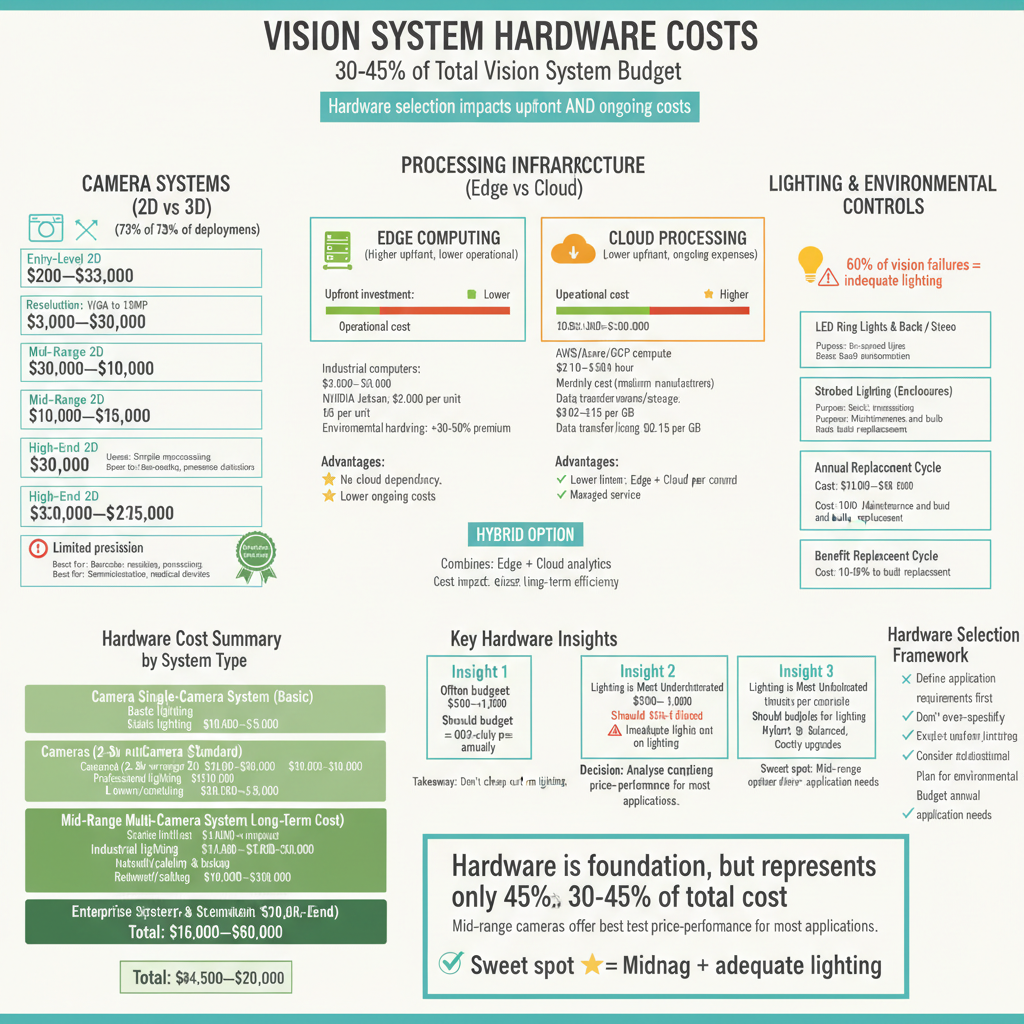

Hardware Costs: The Foundation of Vision System Pricing

Hardware represents 30-45% of total vision system development cost, yet receives disproportionate attention during procurement. Understanding camera specifications, processing requirements, and environmental considerations prevents costly mid-project upgrades.

Camera Systems: 2D vs 3D Vision

2D Vision Cameras dominate manufacturing applications, representing 73% of deployed systems due to lower cost and simpler implementation.

-

Entry-Level 2D Systems ($200-$3,000): VGA to 2MP resolution cameras suitable for barcode reading, basic presence/absence detection, and simple quality checks. These systems work for low-speed lines with minimal defect variation but lack the precision for critical applications.

-

Mid-Range 2D Systems ($3,000-$10,000): 5MP to 12MP resolution with faster processing speeds and better optics. Ideal for automotive component inspection, electronics assembly verification, and pharmaceutical packaging validation. This category offers the best price-performance ratio for most manufacturers.

-

High-End 2D Systems ($10,000-$25,000): Ultra-high-resolution cameras (21MP+) with sophisticated software suites for high-speed automation lines and intricate assembly checks. Semiconductor and medical device manufacturers typically require this tier for micron-level precision.

3D Vision Systems command premium pricing but deliver essential capabilities for volumetric measurement, robot guidance, and complex assembly verification.

-

Entry-Level 3D Systems ($3,000-$10,000): Basic structured light or stereo vision for simple measurements and inspections

-

Mid-Range 3D Systems ($10,000-$30,000): Higher resolution suitable for detailed inspections and precise robot guidance

-

High-End 3D Systems ($30,000-$60,000+): Top-tier resolution for complex applications

Processing Infrastructure: Edge vs Cloud

The processing architecture decision significantly impacts both upfront and ongoing manufacturing AI budget requirements.

Edge Computing Hardware delivers real-time processing with higher initial investment but lower operational costs:

-

Industrial-grade computers: $5,000-$50,000

-

NVIDIA Jetson modules: $2,000-$5,000 per unit

-

Environmental hardening: +30-50% cost premium

Cloud-Based Processing reduces upfront costs but introduces ongoing expenses:

-

AWS, Azure, Google Cloud compute: $0.10-$0.50 per processing hour

-

Monthly cloud costs for medium-volume manufacturer: $2,000-$8,000

-

Data transfer and storage: $0.02-$0.15 per GB

Hybrid Architectures combine edge processing for real-time decisions with cloud analytics, typically adding 20-30% to total system cost but optimizing long-term efficiency.

Lighting and Environmental Controls

Lighting represents the most underestimated hardware cost component, yet 60% of computer vision implementation failures trace to inadequate lighting systems. Professional lighting infrastructure requires:

-

LED ring lights and backlighting systems: $1,000-$5,000 per camera

-

Strobed lighting for high-speed applications: $3,000-$8,000

-

Controlled lighting enclosures: $5,000-$15,000

-

Regular replacement cycles: 10-15% of initial cost annually

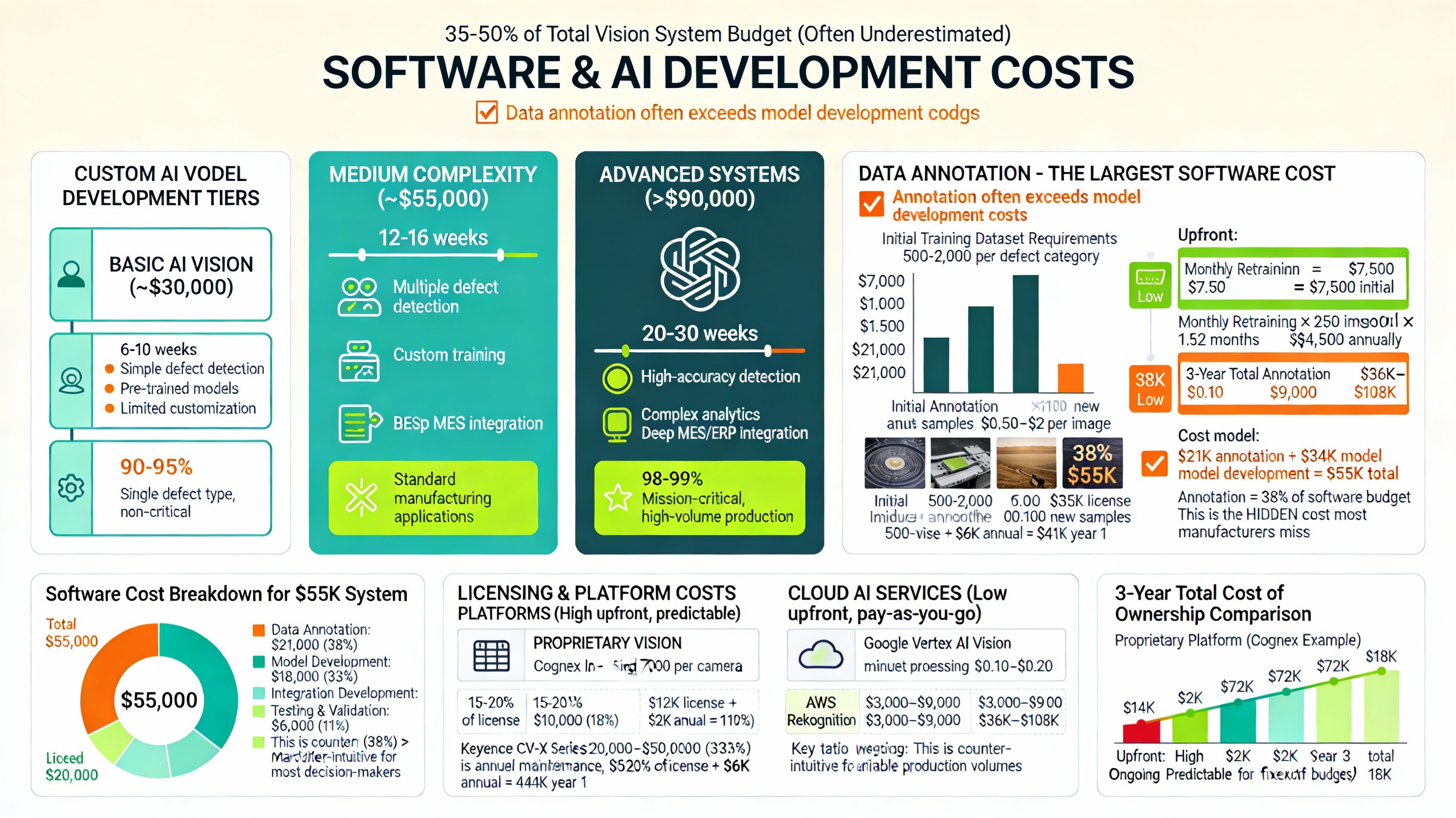

Software Development Costs: The Hidden Budget Killer

Software and AI model development typically consumes 35-50% of total vision system development cost, yet receives inadequate planning during initial budgeting. The complexity gap between off-the-shelf solutions and production-ready systems creates significant cost variance.

Custom AI Model Development Tiers

Basic AI Vision Software (~$30,000): Simple defect detection using pre-trained models with limited customization. Development timeline: 6-10 weeks.

Medium Complexity Solutions (~$55,000): Multiple defect detection capabilities, moderate accuracy requirements (95-97%), and integration with basic manufacturing systems. Development timeline: 12-16 weeks.

Advanced Systems (>$90,000): High-accuracy detection (98-99%), complex analytics, and deep integration with MES/ERP systems. Development timeline: 20-30 weeks.

Data Annotation: The Largest Software Cost

Paradoxically, data annotation often exceeds model development costs in total manufacturing AI budget calculations. A typical manufacturing deployment requires:

-

Initial training dataset: 500-2,000 labeled images per defect category

-

Ongoing data collection: 50-100 new samples monthly

-

Professional annotation services: $0.50-$2 per image

-

Total annotation cost for medium-complexity system: $15,000-$40,000

Annotation Cost Breakdown Example:

-

5 defect categories × 1,000 images each = 5,000 images

-

At $1.50 per image = $7,500 initial annotation

-

Monthly retraining: 250 images × $1.50 × 12 months = $4,500 annually

-

3-year annotation total: $21,000

This represents 38% of the $55,000 medium-complexity software budget.

Licensing and Platform Costs

Proprietary Vision Platforms:

-

Cognex In-Sight 7000 series: $8,000-$20,000 per camera system

-

Keyence CV-X series: $20,000-$50,000 per camera system

-

Annual software maintenance: 15-20% of license cost

Cloud AI Services offer pay-as-you-go models:

-

Google Vertex AI Vision: $0.10-$0.20 per minute processing

-

AWS Rekognition: $0.10-$0.30 per image

-

Monthly cloud costs for 10,000 daily images: $3,000-$9,000

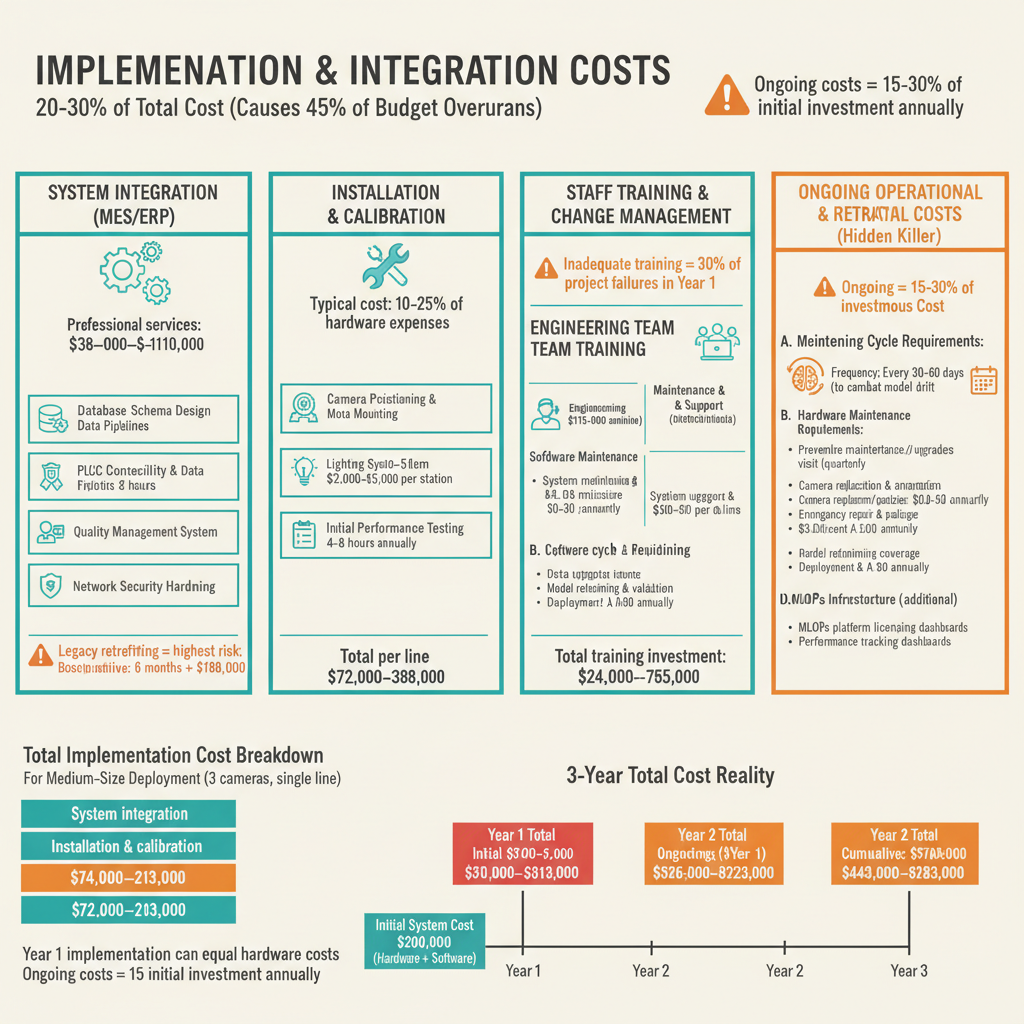

Implementation and Integration Costs

Implementation represents 20-30% of total computer vision cost manufacturing projects, yet causes 45% of budget overruns due to underestimated complexity. Professional integration services typically cost $150-$250 per hour.

System Integration with Manufacturing Infrastructure

MES/ERP Integration requires custom API development:

-

Database schema design: $15,000-$40,000

-

PLC connectivity and real-time data pipelines: $10,000-$30,000

-

Quality management system integration: $8,000-$25,000

-

Network security hardening: $5,000-$15,000

Legacy System Retrofitting presents the highest integration risk. A Bosch automotive components facility required 6 months and $180,000 to integrate computer vision with 20-year-old production equipment.

Installation and Calibration

Professional installation and calibration typically cost 10-25% of upfront hardware expenses:

-

Camera positioning and mounting: $3,000-$8,000 per camera

-

Lighting system optimization: $2,000-$5,000 per station

-

System calibration and validation: $5,000-$15,000 per line

-

Initial performance testing: $4,000-$10,000

Staff Training and Change Management

Inadequate training budgets cause 30% of computer vision project failures within the first year.

Operator Training ($5,000-$25,000 initial):

-

System operation and basic troubleshooting: 16-24 hours

-

Exception handling and manual override: 8-12 hours

-

Ongoing certification: 4-8 hours annually

Engineering Team Training ($15,000-$40,000):

-

System monitoring and performance optimization: 40-60 hours

-

Model retraining and dataset management: 30-50 hours

-

Advanced troubleshooting: 20-40 hours

Hidden and Ongoing Operational Costs

The most significant manufacturing AI budget surprises occur after deployment. Ongoing operational expenses typically equal 15-30% of initial investment annually.

Maintenance and Support Contracts

Hardware Maintenance ($10,000-$50,000 annually):

-

Preventive maintenance visits: $2,000-$5,000 per visit (quarterly)

-

Camera replacement and upgrades: $3,000-$15,000 annually

-

Emergency repair coverage: $5,000-$20,000 annually

Software Maintenance ($15,000-$60,000 annually):

-

Annual support agreements: 15-30% of initial software license cost

-

Version upgrades and security patches: $5,000-$15,000 annually

-

Performance monitoring: $5,000-$20,000 annually

Model Maintenance and Retraining

AI models require continuous maintenance to combat model drift—performance degradation caused by changing production conditions.

Retraining Cycles: Every 30-60 days for optimal accuracy

-

Data collection and annotation: $2,000-$5,000 per cycle

-

Model retraining and validation: $1,500-$4,000 per cycle

-

Deployment and A/B testing: $1,000-$3,000 per cycle

-

Annual retraining cost: $24,000-$72,000

Version Control and Monitoring Infrastructure:

-

MLOps platform licensing: $5,000-$15,000 annually

-

Performance tracking dashboards: $3,000-$8,000 annually

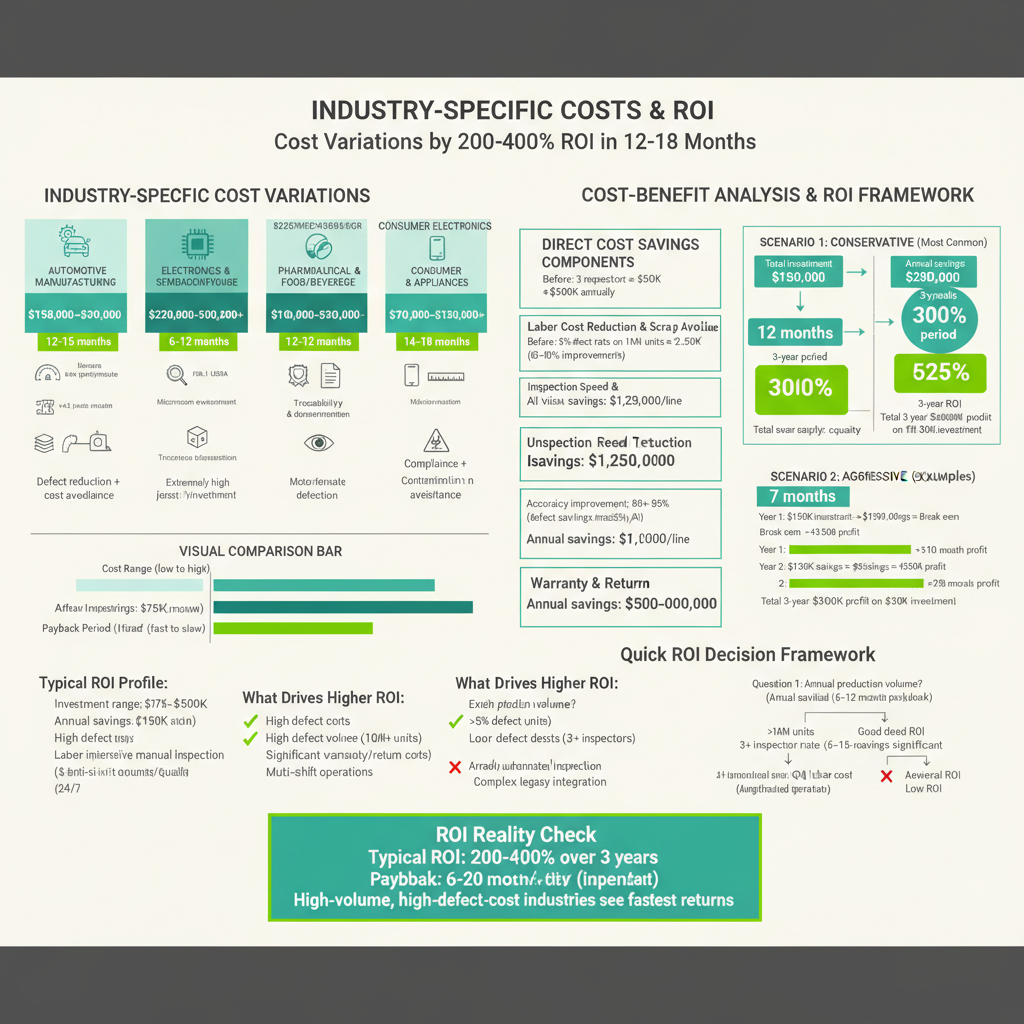

Industry-Specific Cost Variations

Computer vision cost manufacturing varies significantly by industry due to precision requirements, production volumes, and regulatory complexity.

Automotive Manufacturing

Typical System Cost: $150,000-$300,000 per production line

Key Cost Drivers:

- High-speed inspection requirements (60+ parts/minute)

- Precision tolerances (±0.1mm typical)

- Multi-camera arrays for comprehensive coverage

ROI Profile: 12-15 month payback through defect reduction and warranty cost avoidance. Explore Cognex’s automotive vision solutions for detailed specifications.

Electronics and Semiconductor Manufacturing

Typical System Cost: $200,000-$500,000+

Key Cost Drivers:

- Micron-level precision requirements

- Cleanroom environment specifications

- High-resolution 3D inspection

ROI Profile: 6-12 month payback due to extremely high defect costs. Learn more at Keyence’s semiconductor inspection systems.

Pharmaceutical and Food & Beverage

Typical System Cost: $100,000-$250,000

Key Cost Drivers:

- Regulatory compliance validation (FDA, USDA)

- Traceability and documentation requirements

- Contamination detection capabilities

ROI Profile: 12-20 month payback. Explore pharmaceutical packaging inspection solutions.

Consumer Electronics and Appliances

Typical System Cost: $75,000-$150,000

Key Cost Drivers:

- High-volume production (1M+ units annually)

- Cosmetic defect detection

- Moderate precision requirements

ROI Profile: 14-18 month payback through labor reduction and quality consistency.

Cost-Benefit Analysis: ROI Framework

The business case for computer vision cost manufacturing investments rests on quantifiable benefits that typically deliver 200-400% ROI within 12-18 months.

Direct Cost Savings Components

Labor Cost Reduction (40-50% of QA staff):

- Before: 3 inspectors × $50,000 = $180,000 annually

- After: 1 inspector = $60,000 annually

- Annual savings: $120,000 per production line

Defect Reduction and Scrap Avoidance (40-50% improvement):

- Before: 5% defect rate on 1M units = $2,500,000 waste

- After: 2.5% defect rate = $1,250,000 waste

- Annual savings: $1,250,000

Inspection Speed and Throughput:

- Manual inspection: 30 parts/minute maximum

- AI vision: 100+ parts/minute continuous

- Production capacity increase: 15-25%

Customer Return and Warranty Reduction:

- Detection accuracy improvement: 80-85% (manual) to 98-99% (AI)

- Estimated annual savings: $50,000-$200,000

ROI Calculation Examples

Conservative Scenario:

- Total investment: $150,000

- Annual savings: $150,000

- Payback period: 12 months

- 3-year ROI: 300%

Aggressive Scenario:

- Total investment: $200,000

- Annual savings: $350,000

- Payback period: 7 months

- 3-year ROI: 525%

Vendor Pricing Comparison: Cognex vs Keyence vs Emerging Alternatives

Understanding vendor pricing strategies helps manufacturers negotiate better terms and select appropriate technology partners.

Cognex Vision Systems

Cognex represents the premium tier with sophisticated software capabilities. Explore their full product range at Cognex Machine Vision.

In-Sight 7000 Series: $8,000-$15,000 per camera system

In-Sight 9000 Series: $20,000-$35,000 per system

Strengths: Superior defect detection algorithms, extensive training resources, proven reliability in harsh environments

Keyence Vision Systems

Keyence positions as user-friendly alternatives with integrated solutions. Check Keyence Vision Systems for latest offerings.

CV-X Series: $20,000-$35,000

VS Series: $5,000-$12,000

XG-X Series: $40,000-$70,000

Strengths: Exceptional ease of use, local support included, faster deployment times

Cost-Effective Alternatives

Basler Cameras: Industrial camera specialists offering 40-60% cost savings

-

Visit Basler Vision Components for specifications

OMRON and SICK: Mid-tier providers balancing cost and capability

-

Explore OMRON Industrial Vision for options

Emerging AI-First Providers: Cloud-native solutions with SaaS pricing

- Lower upfront hardware costs ($5,000-$15,000)

- Monthly subscription: $1,000-$5,000 per production line

- Faster deployment: 2-4 weeks typical

Ready to cut defect costs by $1.25M annually with computer vision?

Most manufacturers overshoot budgets by 40-60% on first deployment. SmartDev helps you evaluate real CV system pricing, compare costs, and calculate accurate ROI before implementation. Understand hardware ($50K-$150K), software ($30K-$300K), integration complexity, and hidden costs. Build a pilot strategy that delivers 12-18 month payback.

Get transparent pricing, vendor comparison, and ROI analysis tailored to your production line.

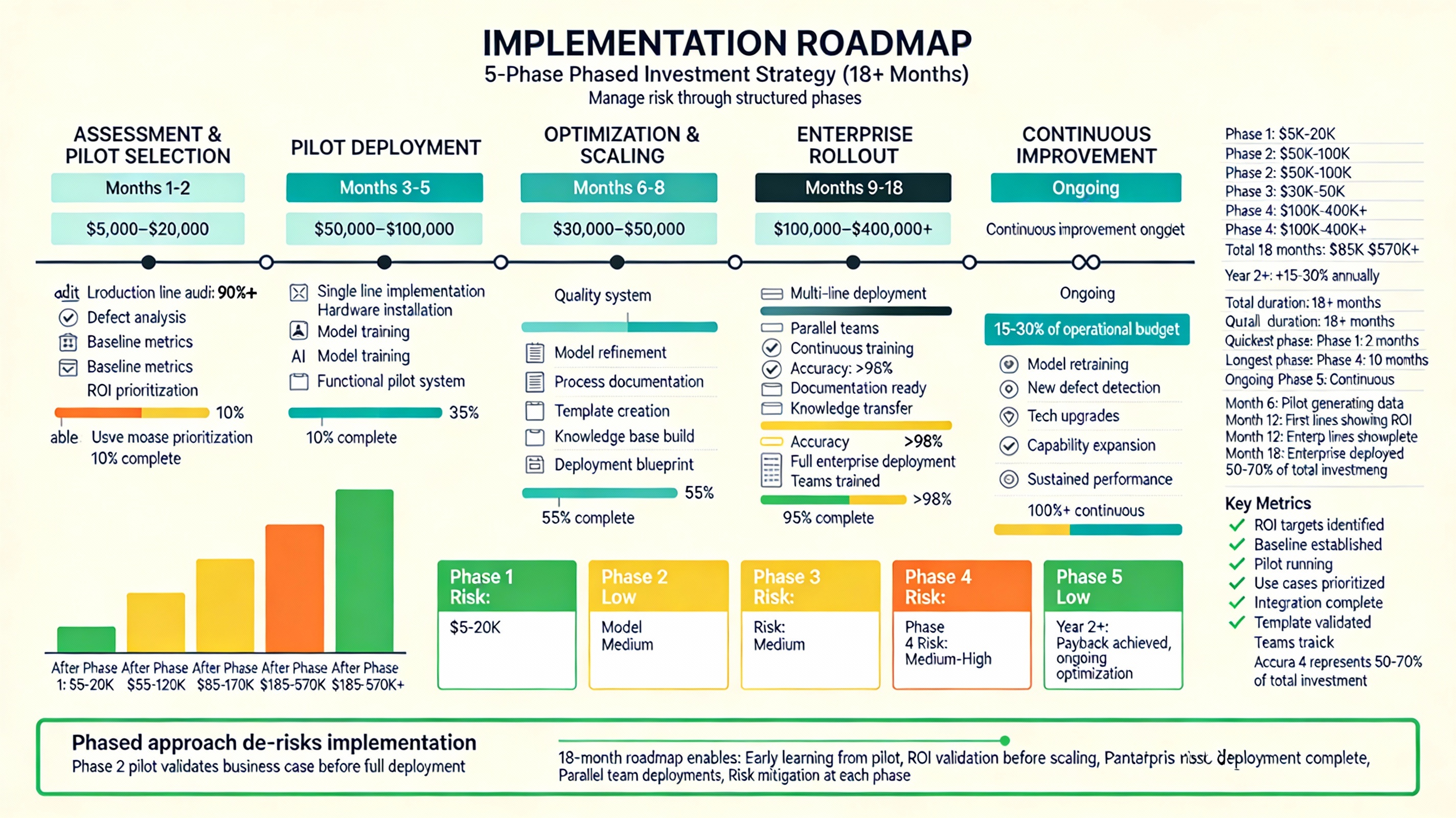

Schedule Your Manufacturing AI Cost Analysis TodayImplementation Roadmap and Phased Investment Strategy

Successful deployments follow structured implementation roadmaps that manage risk and optimize cash flow.

Phase 1: Assessment and Pilot Selection (Months 1-2)

Investment: $5,000-$20,000

- Production line audit and defect analysis

- Baseline metrics establishment

- Use case prioritization based on ROI potential

Phase 2: Pilot Deployment (Months 3-5)

Investment: $50,000-$100,000

- Single production line implementation

- Hardware installation and calibration

- Initial model training with production data

- Integration with existing quality systems

Phase 3: Optimization and Scaling (Months 6-8)

Investment: $30,000-$50,000

- Model refinement based on pilot data

- Process standardization and documentation

- Deployment template creation for additional lines

- Phase 4: Enterprise Rollout (Months 9-18)

Investment: $100,000-$400,000+

- Phased deployment across remaining production lines

- Parallel implementation teams for faster rollout

- Continuous training and knowledge transfer

Phase 5: Continuous Improvement (Ongoing)

Annual Investment: 15-30% of operational budget

- Model retraining and performance optimization

- New defect type identification and model updates

- Technology upgrades and capability expansion

For detailed implementation guidance, visit Jidoka’s AI implementation framework.

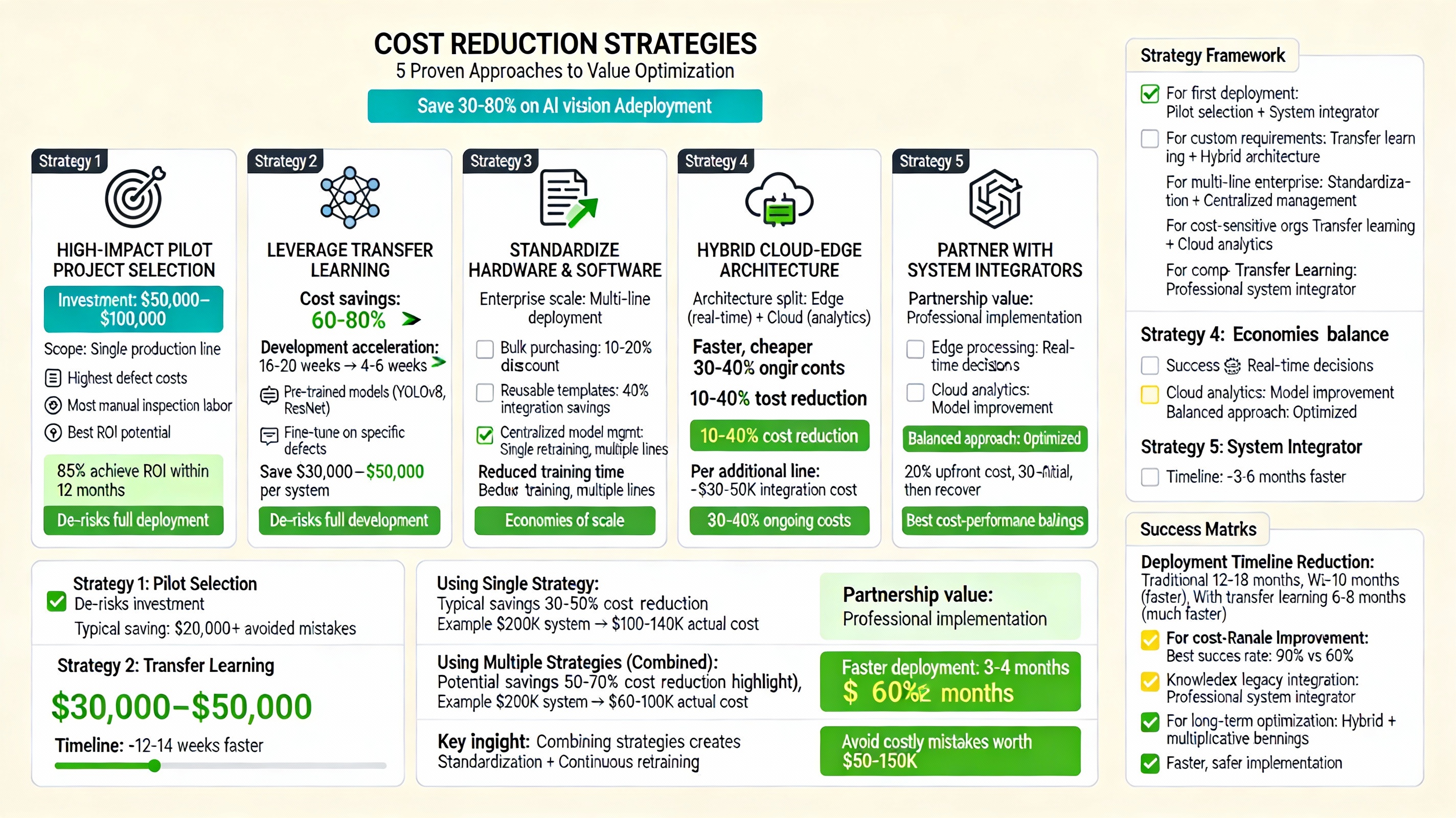

Cost Reduction Strategies and Value Optimization

Strategy 1: High-Impact Pilot Project Selection

Identify the single production line with highest defect costs and most manual inspection labor. Typical pilot investment: $50,000-$100,000. Success rate: 85% achieve ROI within 12 months.

Strategy 2: Leverage Transfer Learning

Modern approaches using transfer learning reduce costs by 60-80%:

- Start with pre-trained models (YOLOv8, ResNet) instead of training from scratch

- Fine-tune on your specific defects

- Development time: 16-20 weeks → 4-6 weeks

- Cost savings: $30,000-$50,000 per system

Learn more about ML frameworks at PyTorch and TensorFlow documentation.

Strategy 3: Standardize Hardware and Software Platforms

Enterprise standardization delivers significant economies:

- Bulk purchasing discounts: 10-20% reduction

- Reusable deployment templates: Reduce per-line integration costs by 40%

- Centralized model management: Single retraining serves multiple lines

Strategy 4: Hybrid Cloud-Edge Architecture

Hybrid approaches optimize cost-performance balance:

- Edge processing for real-time decisions and production control

- Cloud analytics for model improvement

- Cost Impact: Hybrid adds 20% to initial investment but reduces ongoing costs by 30-40%

- Discover integration partners at Basler integrator network.

Strategy 5: Partner with Experienced System Integrators

Professional integration prevents expensive mistakes:

- Faster deployment: 3-4 months vs 6-12 months

- Success rate: 90% vs 60% for first-time internal implementations

- Knowledge transfer: Teams learn best practices during implementation

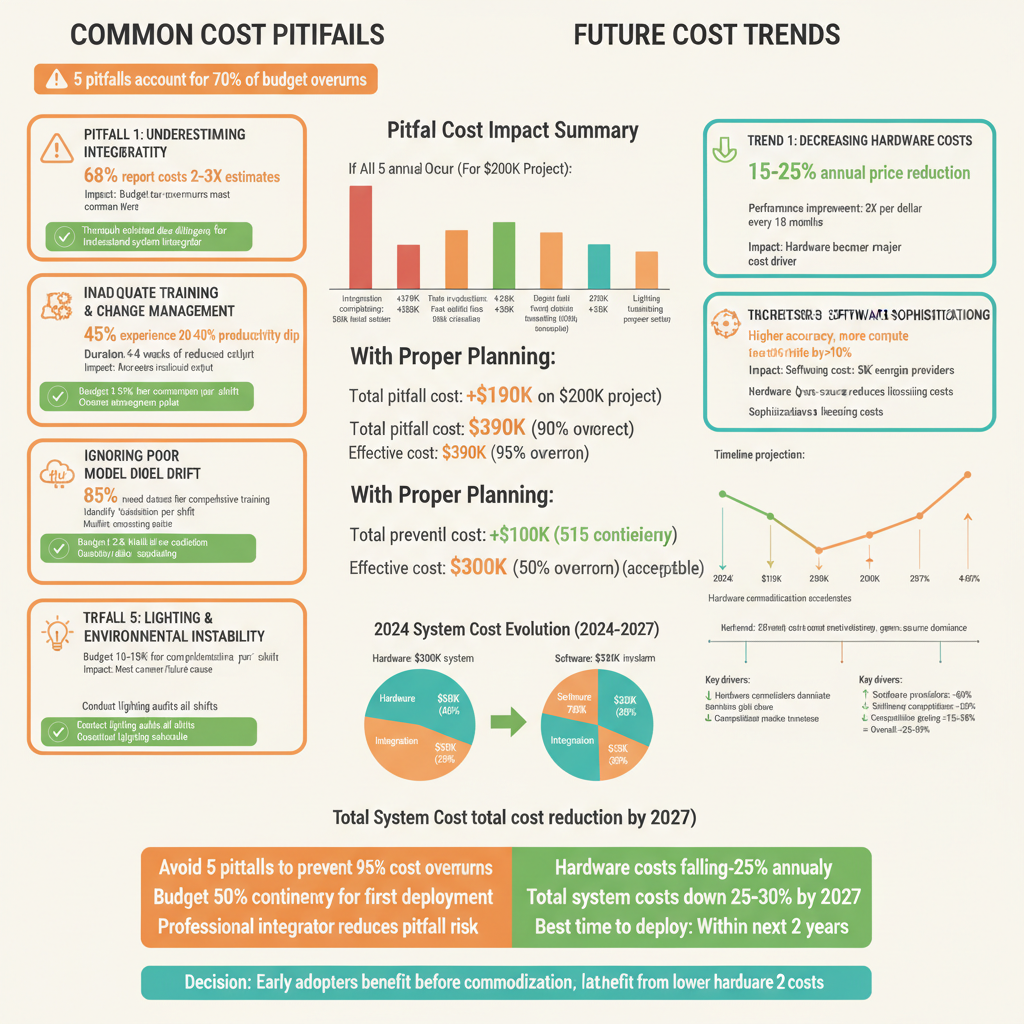

Common Cost Pitfalls and How to Avoid Them

Pitfall 1: Underestimating Integration Complexity

68% of manufacturers report integration costs 2-3x initial estimates. Conduct thorough technical due diligence before budgeting. Budget 50% contingency for integration costs. Learn from Xenoss’s hidden cost analysis.

Pitfall 2: Inadequate Training and Change Management

45% experience productivity dips of 20-40% for 4-8 weeks. Budget 10-15% of project cost for comprehensive training. Identify “vision champions” on each shift. Explore NobleProg’s computer vision training.

Pitfall 3: Poor Data Quality

55% require dataset expansion within 3 months. Collect data across all shifts and variations. Budget for 2-3x initial data collection estimate. Understand the importance from Roboflow’s AI manufacturing guide.

Pitfall 4: Ignoring Model Drift

85% underestimate ongoing costs by >10%. Budget 15-30% of initial software cost for annual maintenance. Schedule monthly performance reviews and quarterly retraining.

Pitfall 5: Lighting and Environmental Instability

60% of failures trace to inconsistent lighting. Invest in controlled lighting systems ($10,000-$30,000 per station). Conduct lighting audits across all shifts. For guidance, see Cognex’s vision lighting guide.

Future Cost Trends and Market Evolution

Decreasing Hardware Costs

Camera sensor commoditization drives 15-25% annual price reductions for equivalent resolution. NVIDIA Jetson and Intel Movidius platforms deliver 2x performance improvement per dollar every 18 months.

Increasing Software Sophistication

State-of-the-art models require more computational resources but deliver higher accuracy. Cloud training costs: $5,000-$15,000 vs $2,000-$5,000 for traditional approaches.

Market Growth and Competitive Pricing

The industrial machine vision market’s 12.3% annual growth attracts new entrants. Emerging providers from China, Korea, and India offer comparable hardware at 30-50% lower prices. Open-source ecosystems reduce software licensing costs significantly.

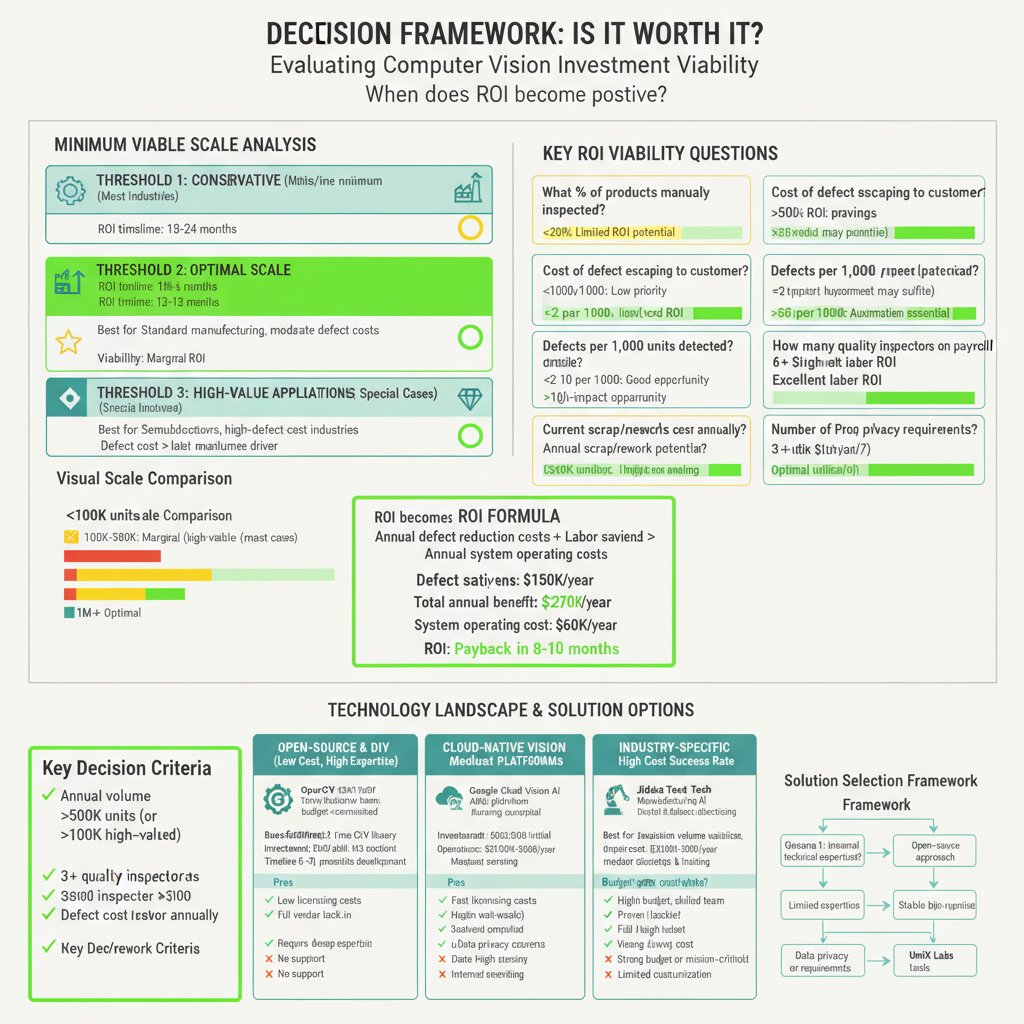

Decision Framework: Is Computer Vision Worth the Investment?

Manufacturing leaders need clear criteria for evaluating computer vision cost manufacturing decisions.

Minimum Viable Scale Analysis

Computer vision becomes cost-effective when labor automation savings exceed system costs:

Conservative Threshold: 500,000 units annually per production line

Optimal Scale: 1M+ units annually per production line

High-Value Applications: 100K+ units annually (semiconductors, high-defect-cost industries)

Key Questions to Determine ROI Viability

- What percentage of products are currently manually inspected?

- What is the cost of a defect escaping to the customer?

- How many defects per 1,000 units currently detected?

- What is production line speed (parts per minute)?

- How many quality inspectors are on payroll?

- What is current scrap/rework cost annually?

ROI becomes positive when: Annual defect reduction costs + labor savings > Annual system operating costs

Technology Landscape: Latest Platforms and Solutions

Open-Source and DIY Approaches

For manufacturers with strong technical capabilities, open-source frameworks offer cost-effective alternatives:

- OpenCV – Free computer vision library

- TensorFlow – Open-source ML platform

- PyTorch – Machine learning framework for research and production

Cloud-Native Vision Platforms

Modern SaaS offerings democratize computer vision:

- Google Cloud Vision AI

- AWS Rekognition

- Azure Computer Vision

- Roboflow Enterprise – Dataset and model management

Industry-Specific Solutions

Vertical-specific platforms address manufacturing challenges directly:

- Jidoka Tech – Manufacturing AI focus

- Overview AI – Defect detection accuracy

- SmartDev – Quality control solutions

- UnitX Labs – ROI calculation tools

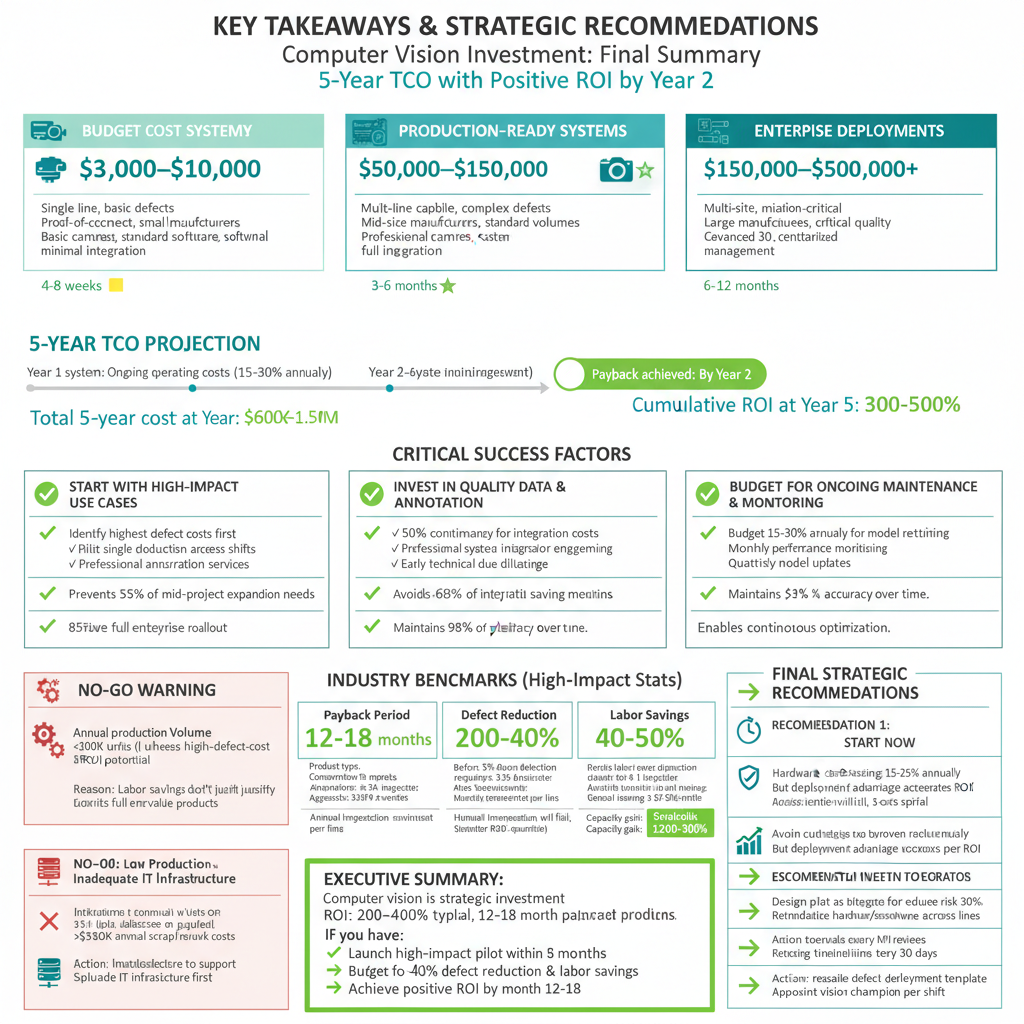

Key Takeaways and Strategic Recommendations

Typical Cost Summary:

- Budget systems: $3K-$10K

- Production-ready systems: $50K-$150K

- Enterprise deployments: $150K-$500K+

- 5-year TCO: $600K-$1.5M (with positive ROI by year 2)

Critical Success Factors:

- Start with high-impact, high-ROI use cases

- Invest in quality training data and annotation

- Plan for integration complexity upfront

- Budget for ongoing model maintenance (15-30% annually)

- Establish clear KPIs and performance monitoring

When NOT to Implement:

- Annual production volume <100K units (unless high-defect costs)

- Highly variable/custom products requiring constant retraining

- Inadequate IT infrastructure for integration support

Industry Benchmarks:

- Payback period: 12-18 months typical

- Annual ROI: 200-400%

- Defect reduction: 40-50%

- Labor savings: 40-50% of QA staff

- Processing speed: 100x faster than humans

Next Steps: Starting Your Computer Vision Journey

- Conduct ROI Analysis: Use the framework provided to calculate your specific payback period

- Identify High-Impact Lines: Select 1-2 production lines with highest defect costs for pilot

- Request Vendor Quotes: Contact Cognex, Keyence, Basler, and emerging providers for competitive bids

- Schedule Technical Assessment: Arrange facility audits to understand integration requirements

- Build Business Case: Develop detailed implementation plan with stakeholder buy-in

Additional Resources and Further Reading

For continued education and industry insights:

- Roboflow’s Manufacturing AI Guide – Comprehensive AI implementation strategies

- Calvary Robotics ROI Guide – Understanding manufacturing ROI

- Engineered Vision’s ROI Calculator – Automated ROI calculation

- UnitX Labs Visual Inspection ROI – Latest ROI metrics

- Food Industry Executive’s Vision Benefits – Industry-specific insights

- Tech-Stack’s AI Manufacturing Guide – Adoption best practices

- Averroes AI Vision Comparison – Vendor comparison

Final Recommendations

The window for competitive advantage through manufacturing automation is narrowing. Manufacturers who implement vision systems in 2025-2026 will establish quality and efficiency advantages that competitors can only chase. The cost-benefit analysis is clear: the question is not whether to invest, but when and how to optimize that investment.

For immediate action: Schedule a 30-day technical assessment with your top 2-3 preferred vendors. Most offer free consultations that clarify integration requirements and refine cost estimates. This small upfront investment ($0-$5,000 in evaluation costs) eliminates surprises during actual implementation.

For risk mitigation: Always structure implementations as phased pilots. A $50,000-$100,000 pilot investment over 3-5 months provides proof of concept with lower risk than enterprise-wide rollout. Success metrics from pilot (defect detection rate, labor savings, payback timeline) drive funding decisions for scaling.